PRODUCT

How are materials used by WAXING for producing linear ball bearings?

2020-11-28

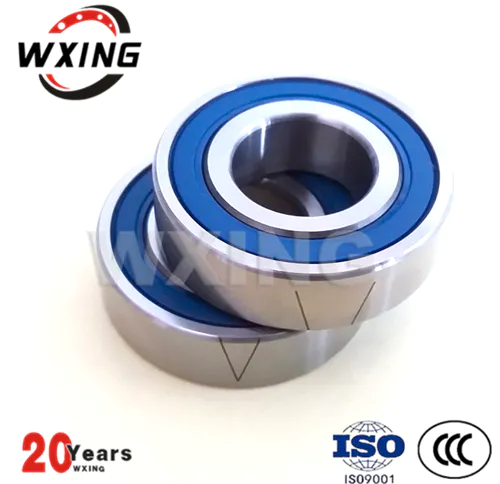

Our responsibility for quality starts with the selection of materials. We have a responsibility to make sure our suppliers take care of their materials. We use industry-wide guidelines to assess their materials and select only the best. And before we put the raw materials into production, we have a materials testing procedure. Our expert team will carefully test the materials to ensure that they are suitable for processing and meet the safety and quality requirements. Our strict quality control over the raw materials ensures you only get high-quality and high-performing linear ball bearings.

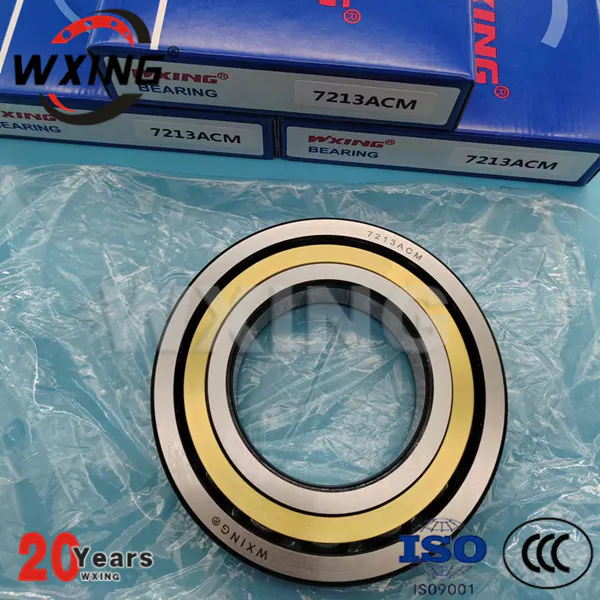

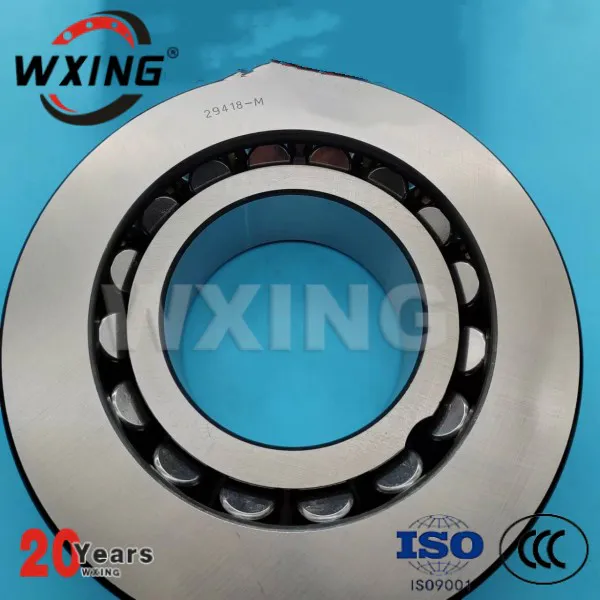

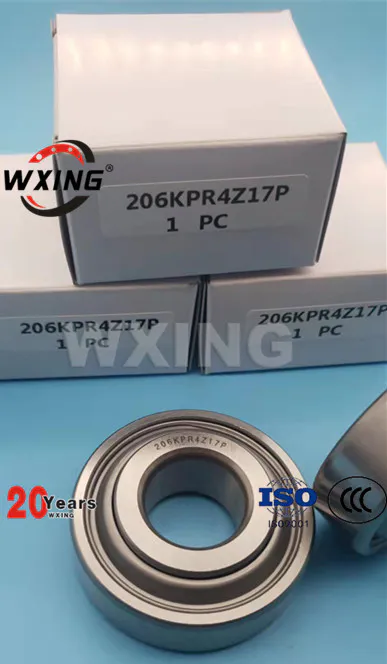

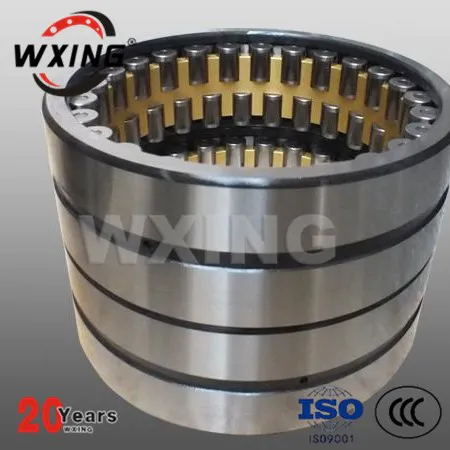

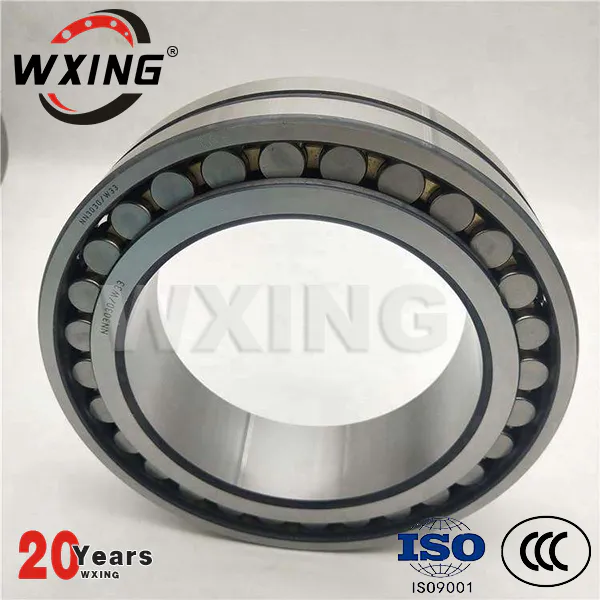

Zhejiang waxing electromechanical co.LTD. has a front-runner status when speaking of bike chain tensioner. Zhejiang Waxing Electromechanical Co., Ltd's bike chain tensioner is various in types and styles to meet the different needs of customers. Waxing universal joint bearing is produced based on the highest standards. It can show its good mechanical properties even at a high temperature. The product is of high precision. It is manufactured by a variety of specialized CNC machines such as a cutting machine, punching machine, polishing machine, and grinding machine. The high-quality roller bearing can help the product achieve high thrust capacity.

Zhejiang waxing electromechanical co.LTD. has always upheld 'Good Faith as Principle'. Call now!

Zhejiang waxing electromechanical co.LTD. has a front-runner status when speaking of bike chain tensioner. Zhejiang Waxing Electromechanical Co., Ltd's bike chain tensioner is various in types and styles to meet the different needs of customers. Waxing universal joint bearing is produced based on the highest standards. It can show its good mechanical properties even at a high temperature. The product is of high precision. It is manufactured by a variety of specialized CNC machines such as a cutting machine, punching machine, polishing machine, and grinding machine. The high-quality roller bearing can help the product achieve high thrust capacity.

Zhejiang waxing electromechanical co.LTD. has always upheld 'Good Faith as Principle'. Call now!

Custom message