SC8LUU Linear Motion Ball Bearing Slide Unit Block SCS8LUU Long Type for CNC Router Slide Block

Quality Grade: High Grade

Block Material: Aluminium case + high grade linear bearing

Surface Treatment: Sandblasting oxidation

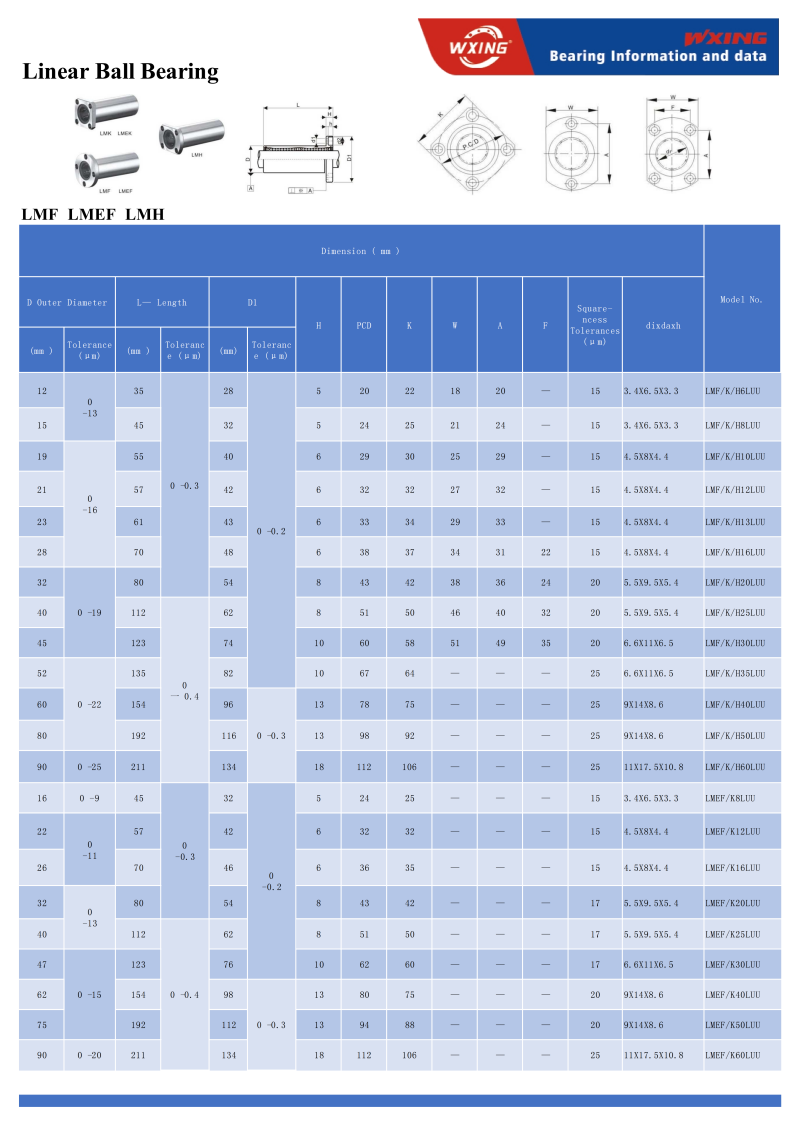

Main Dimensions: detail size in the belowing datasheet

Main Applications: CNC parts, 3d printer parts, Automation parts

Material: Aluminum

Vibration in stainless steel linear bearings during operation must be dealt with in time. There are many ways to deal with this situation, but which method is the most suitable for the bearing? Today we will focus on this issue. In the past, customers always came to us to tell us about problems with the bearing vibration series. We also gave many replies, but at present, this situation still exists.

If there are cracks, indentations or rust on the rolling surface of general stainless steel linear bearings, periodic vibration and noise will occur like riveting rivets. The period can be fixed but most of them have a certain corresponding relationship with the rotation speed. The scars will appear on the raceway. It will continue to occur, and the scars will appear and disappear on the steel ball. After assembling the bearing and the shaft and then installing it into the bearing seat, avoid installing the bearing at an angle, avoid bearing corrosion during storage, and avoid shock and vibration during transportation. In case the above problems occur during use, we should take corresponding measures in time so as to better solve the problem.

1 Gasket method:

Put the bearing in the bearing cap, put a face to fill the spacer between the soft material (soft or flexible steel paper), adjust, hold it for the first time, install the bearing cap gasket on one hand, and tighten the bearing end cap screws evenly, Hand the square shaft until the stainless steel linear bearing is in contact with the outer shaft until there is no gap in the house, and then measure the gap between the bearing cover and the bearing surface. The bearing needs to add the axial gap during normal working hours, which needs to be filled with pads. The total thickness of the piece is then prepared to fill the bearing cap with a gasket, between the bearing surfaces, and finally tighten the screws.

2. How to adjust the bolts:

Before adjusting the pressure on the outer ring of the stainless steel linear bearing, measure the first ball of the pressure adjustment bolt to measure the adjustment bolt, and then slowly tighten the adjustment screw until the internal bearing clearance is reached. Then calculate the corresponding rotation angle of the pressure of the adjustment bolt.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.

CONTACT US

Consult our customers for surprise discounts.