PRODUCT

How about production process for clutch bearing?

2021-11-27

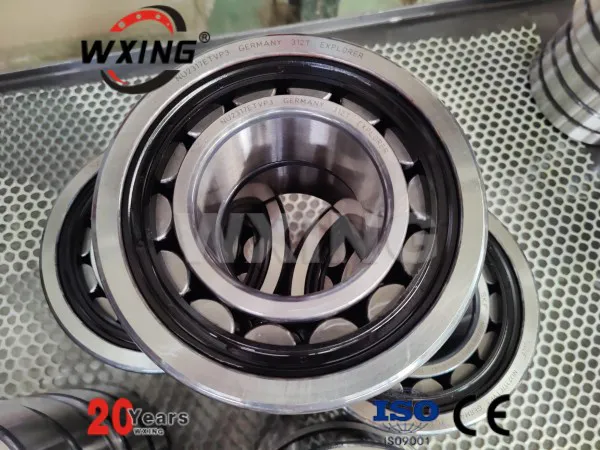

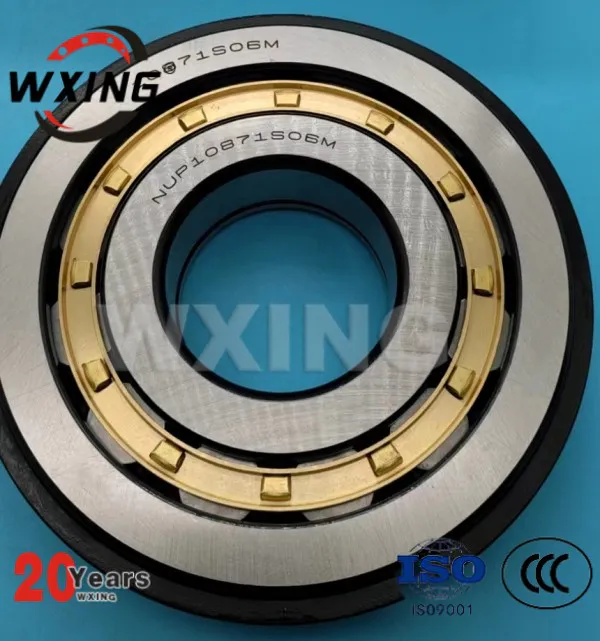

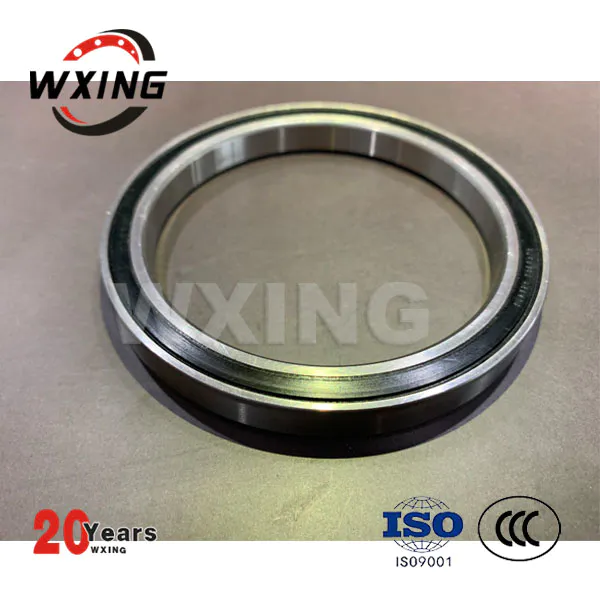

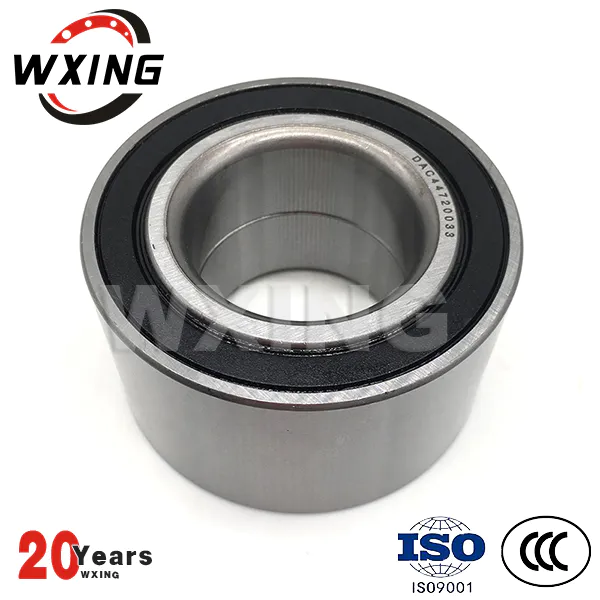

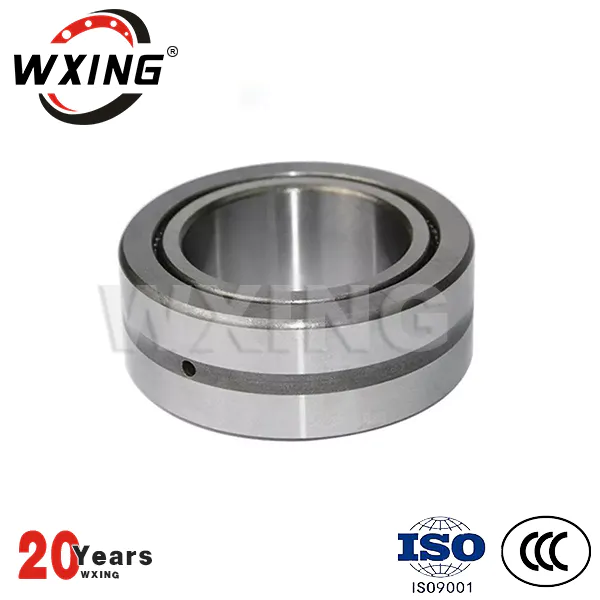

A complete set of production process of clutch bearing needs to be performed from raw materials introduction to finished product sales. As for the crafts process, it is the most basic part during the production process. Each crafts step should be conducted by professional technicians to ensure the quality of products. Offering considerate service is part of production process. Equipped with skilled after-sales service team, Zhejiang Waxing Electromechanical Co., Ltd can efficiently solve the problems after you purchase the products.

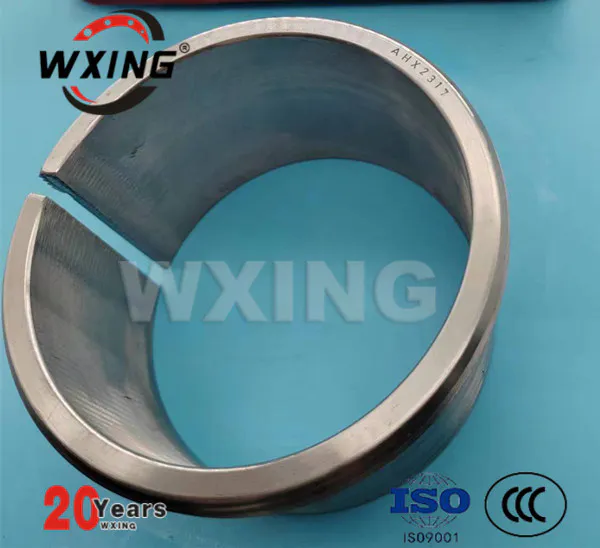

Zhejiang waxing electromechanical co.LTD. is a mainstay Chinese enterprise of joint bearing. According to the material, WAXING's products are divided into several categories, and universal joint bearing is one of them. Waxing spherical roller thrust bearing dimensions is required to go through several performance tests. They are water washability, breathability, impact resistance, tearing strength, and rub colorfastness testing. With a compact radial structure, it has a strong bearing capacity. Strict quality control system is the guarantee of product quality. The internal structure of the product compensates for shaft deflections and housing distortions caused by the heavy loads.

Winning the favor of customers need the effort of Waxing each staff. Check it!

Zhejiang waxing electromechanical co.LTD. is a mainstay Chinese enterprise of joint bearing. According to the material, WAXING's products are divided into several categories, and universal joint bearing is one of them. Waxing spherical roller thrust bearing dimensions is required to go through several performance tests. They are water washability, breathability, impact resistance, tearing strength, and rub colorfastness testing. With a compact radial structure, it has a strong bearing capacity. Strict quality control system is the guarantee of product quality. The internal structure of the product compensates for shaft deflections and housing distortions caused by the heavy loads.

Winning the favor of customers need the effort of Waxing each staff. Check it!

Custom message