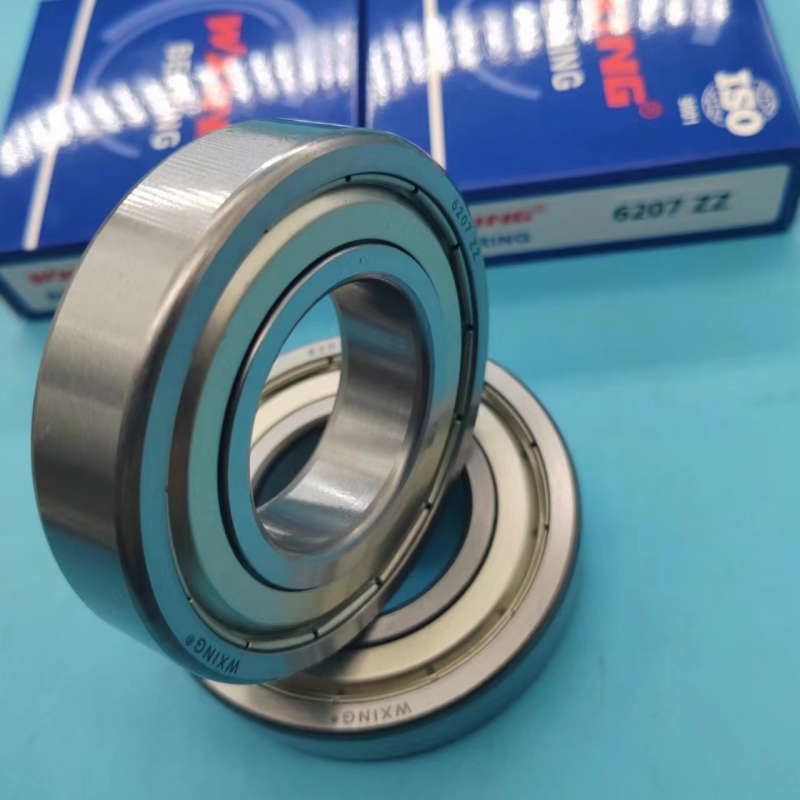

| Product Name | 95x170x32mm 6219zz deep groove ball bearing |

| Brand | WXING |

| Model No | 6219ZZ |

| Sizes(mm) | 95x170x32mm |

| Material | Chrome steel/100Cr6, GCr15 bearing steel |

| Sealed Type | 2RS rubber seals/ ZZ metal shields/Open |

| Precision | P0, P5, P6 |

| Clearance | C0, C2, C3, C4 |

| Used | 95x170x32mm 6219zz deep groove ball bearing 6219 z |

| Packing | 10pcs/tube+White small box+Carton |

| Shipping Method | By air or by sea |

The first point is to keep the bearing and its surrounding environment clean.

You don’t need to tell me what’s going on. Even if dust invisible to the naked eye enters the bearing, it will cause the bearing to wear. To put it bluntly, you can’t rub a little bit of sand into your eyes. This is the truth!

The second point is to install carefully and accurately when using and installing.

The second point is to install carefully and accurately when using and installing.

You don’t even know this bit of common sense. If you don’t, then don’t make deep groove ball bearings and go home and play. The most important thing is that strong stamping is not allowed and hammers are not allowed to directly hit the bearings. It's not that you're afraid of smashing it, but you're deformed by it. What should you do? Just bear the loss yourself, haha. Also, it's not allowed to transmit pressure through the body.

The third point is to use appropriate and accurate installation tools.

Try to use special tools and avoid using things like cloth and short fibers.

The fourth point is to prevent the bearings from rusting and do not soak them with water.

The bearing is made of fine steel, but it is also afraid of water. If you don't believe it, just put it in the water for a bath. Haha, when taking the bearing with your hands, you must fully wash off the sweat on your hands and apply high-quality mineral oil before operating it. , especially in the rainy season and summer, you must pay attention to rust prevention. Don't tell me what you are afraid of from rust. Well, try it yourself and see what the consequences of rust will be!

Even if a few bearings produce abnormal and irregular sounds in the fatigue peeling state, it is possible to hear them if you are skilled.

Use a bearing vibrator to quantitatively measure and analyze the vibration amplitude, frequency, etc., and infer the damage status of the deep groove ball bearing based on this.

However, since the operating conditions of the bearings and the measurement locations are different, it is necessary to make use of the measured values of the machine to determine the criteria for judgment.

The bearing temperature usually rises slowly after the operation starts and reaches a saturated state after a period of time. The steady temperature of bearings varies depending on mechanical heat capacity, heat release, rotation speed and load.

If the bearing temperature rises abnormally before it reaches the saturated state, consider the reasons shown on the following page, stop operation and take necessary countermeasures.

Investigating the grease and lubricating oil in use is effective in understanding the operating conditions of the bearings. Of course, the leakage, discoloration and deterioration of grease or oil can be judged from the moisture, debris, iron powder, etc. contained in it.

When it is believed that there is lubricant leakage or the mixing of foreign matter such as iron powder and metal powder, the leakage amount, temperature and vibration of the deep groove ball bearing should be regularly observed quantitatively. If any abnormalities are found, early maintenance should be carried out.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.

CONTACT US

Consult our customers for surprise discounts.