CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

Product Description:

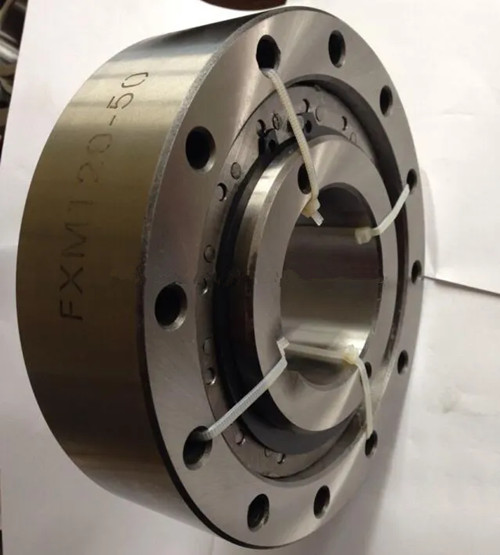

The one-way clutch FXM with centrifugal non-contact X series one-way clutch bearings.When the inner ring speed high, run a one-way clutch wear.

Suitable for high-speed idling operation and low-speed synchronous operation, the rated torque can reach 364000Nm, and the inner hole diameter can reach 320mm.

Freewheel one way clutch bearing CKA relative series

Sprag lift-off X

Integrated Freewheels FXM are equipped with sprag lift-off X. The sprag lift-off X is used for backstops and overrunning clutches, provided that in freewheeling operation the inner ring is rotating at high speed and providing with overrunning clutches that the driving operation is conducted at low speed.

In freewheeling operation, the centrifugal force FC causes the sprag to lift off from the outer track. In this operating state, the freewheel works wear-free, i.e. with unlimited service life.

Dimensions and Capacities:

| Type | d | A | B | D | E | F | G | J | L | P | T | U | V | W | Z** | w | ||||||

| bore | ||||||||||||||||||||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | |||

| FXM | 20* | 20* | 17 | 25 | 85 | 41 | 55 | M6 | 31 | 24 | 1,0 | 70 | 15 | 6 | 21 | 6 | 0,8 | |||||

| 31 -17 | ||||||||||||||||||||||

| FXM | 25* | 25* | 17 | 25 | 90 | 48 | 62 | M6 | 38 | 24 | 1,0 | 75 | 15 | 6 | 21 | 6 | 0,9 | |||||

| 38 -17 | ||||||||||||||||||||||

| FXM | 25 | 30 | 25 | 35 | 95 | 56 | 70 | M6 | 46 | 35 | 1,0 | 82 | 15 | 6 | 21 | 6 | 1,3 | |||||

| 46 -25 | ||||||||||||||||||||||

| FXM | 25 | 30 | 35 | 36 | 25 | 35 | 105 | 62 | 75 | M6 | 51 | 35 | 1,0 | 90 | 15 | 6 | 21 | 6 | 1,7 | |||

| 51 -25 | ||||||||||||||||||||||

| FXM | 35 | 40 | 25 | 35 | 110 | 66 | 80 | M6 | 56 | 35 | 1,0 | 96 | 15 | 6 | 21 | 8 | 1,8 | |||||

| 56 -25 | ||||||||||||||||||||||

| FXM | 30 | 35 | 40 | 45* | 19 | 27 | 120 | 74 | 85 | M8 | 61 | 25 | 1,0 | 105 | 15 | 6 | 21 | 6 | 1,8 | |||

| 61 -19 | ||||||||||||||||||||||

| FXM | 35 | 40 | 45 | 48* | 25 | 35 | 132 | 82 | 90 | M8 | 66 | 35 | 1,0 | 115 | 15 | 8 | 23 | 8 | 2,8 | |||

| 66 -25 | ||||||||||||||||||||||

| FXM | 45 | 55 | 60* | 25 | 35 | 140 | 92 | 100 | M8 | 76 | 35 | 1,0 | 125 | 15 | 8 | 23 | 8 | 3,1 | ||||

| 76 -25 | ||||||||||||||||||||||

| FXM | 40 | 45 | 50 | 60 | 65 | 70* | 25 | 40 | 150 | 102 | 110 | M8 | 86 | 40 | 1,0 | 132 | 15 | 8 | 23 | 8 | 4,2 | |

| 86 -25 | ||||||||||||||||||||||

| FXM | 55 | 70 | 80* | 25 | 50 | 175 | 117 | 125 | M10 | 101 | 50 | 1,0 | 155 | 20 | 8 | 28 | 8 | 6,9 | ||||

| 101 -25 | ||||||||||||||||||||||

| FXM | 45 | 50 | 60 | 65 | 65 | 40 | 50 | 175 | 102 | 125 | M10 | 85 | 60 | 1,0 | 155 | 20 | 8 | 28 | 8 | 7,4 | ||

| 85 -40 | ||||||||||||||||||||||

| FXM | 45 | 50 | 55 | 60 | 70 | 75 | 80* | 40 | 50 | 190 | 130 | 140 | M10 | 100 | 60 | 1,5 | 165 | 25 | 10 | 35 | 12 | 8,8 |

| 100 -40 | ||||||||||||||||||||||

| FXM | 60 | 65 | 70 | 75 | 80 | 95 | 95 | 50 | 60 | 210 | 150 | 160 | M10 | 120 | 70 | 1,5 | 185 | 25 | 10 | 35 | 12 | 12,7 |

| 120 -50 | ||||||||||||||||||||||

| FXM | 65 | 90 | 100 | 110 | 110 | 50 | 70 | 245 | 170 | 180 | M12 | 140 | 70 | 2,0 | 218 | 25 | 12 | 35 | 12 | 19,8 | ||

| 140 -50 | ||||||||||||||||||||||

| FXM | 70 | 85 | 90 | 100 | 120 | 130 | 63 | 80 | 290 | 200 | 210 | M16 | 170 | 80 | 2,0 | 258 | 28 | 12 | 38 | 12 | 33,0 | |

| 170 -63 | ||||||||||||||||||||||

| FXM | 130 | 155 | 63 | 80 | 310 | 230 | 240 | M16 | 200 | 80 | 2,0 | 278 | 32 | 12 | 42 | 12 | 32,0 | |||||

| 200 -63 | ||||||||||||||||||||||

| FXM | 185 | 63 | 80 | 400 | 280 | 310 | M20 | 240 | 90 | 2,0 | 360 | 48 | 15 | 60 | 12 | 60,0 | ||||||

| 240 - 63 | ||||||||||||||||||||||

| FXM | 185 | 96 | 125 | 420 | 280 | 310 | M24 | 240 | 120 | 2,0 | 370 | 48 | 18 | 60 | 16 | 95,0 | ||||||

| 240 - 96 | ||||||||||||||||||||||

| FXM | 205 | 63 | 80 | 430 | 300 | 330 | M20 | 260 | 105 | 2,0 | 380 | 48 | 18 | 60 | 16 | 75,0 | ||||||

| 260 - 63 | ||||||||||||||||||||||

| FXM | 230 | 70 | 80 | 460 | 330 | 360 | M20 | 290 | 105 | 2,0 | 410 | 48 | 18 | 60 | 16 | 90,0 | ||||||

| 290 - 70 | ||||||||||||||||||||||

| FXM | 230 | 96 | 110 | 460 | 330 | 360 | M20 | 290 | 120 | 2,0 | 410 | 48 | 18 | 60 | 16 | 91,0 | ||||||

| 290 - 96 | ||||||||||||||||||||||

| FXM | 240 | 70 | 125 | 497 | 360 | 380 | M20 | 310 | 110 | 3,0 | 450 | 48 | 18 | 60 | 24 | 135,0 | ||||||

| 310 - 70 | ||||||||||||||||||||||

| FXM | 240 | 96 | 125 | 497 | 360 | 380 | M20 | 310 | 120 | 3,0 | 450 | 48 | 18 | 60 | 24 | 145,0 | ||||||

| 310 - 96 | ||||||||||||||||||||||

| FXM | 250 | 70 | 80 | 490 | 360 | 390 | M24 | 320 | 105 | 3,0 | 440 | 55 | 20 | 68 | 16 | 105,0 | ||||||

| 320 - 70 | ||||||||||||||||||||||

| FXM | 280 | 100 | 120 | 540 | 400 | 430 | M24 | 360 | 125 | 3,0 | 500 | 55 | 20 | 68 | 24 | 170,0 | ||||||

| 360 - 100 | ||||||||||||||||||||||

| FXM | 320 | 100 | 120 | 630 | 460 | 480 | M24 | 410 | 125 | 3,0 | 560 | 55 | 20 | 68 | 24 | 245,0 | ||||||

| 410 - 100 | ||||||||||||||||||||||

| FXM | 320 | 200 | 220 | 630 | 460 | 480 | M30 | 410 | 220 | 3,0 | 560 | 55 | 20 | 68 | 24 | 440,0 | ||||||

| 2410 - 100 | ||||||||||||||||||||||

Application:

Notes:

The maximum transmissible torque is 2 times the specified nominal torque.

The theoretical nominal torque applies only for ideal concentricity between the inner and outer ring. In practice, the concentricity is affected by the bearing play and centering errors of the neighbouring parts.

Then the nominal torques specified in the table apply, while taking into consideration the existing run out (T.I.R.). Higher speeds upon request.

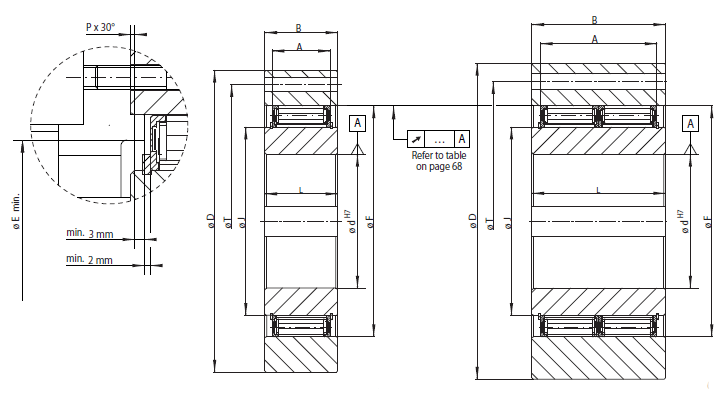

Mounting:

Integrated Freewheels FXM are without bearing support. Concentric alignment of inner and outer ring must be provided by the customer. The permissible run out (T.I.R.) must be observed. The Integrated Freewheel FXM is centered via the outer track F on the customer attachment part and bolted to this .

The tolerance of the pilot diameter of the attachment part must be ISO h6 or h7.

The tolerance of the shaft must be ISO h6 or j6. For fitting to shaft ends, end covers can be supplied upon request.

Lubrication:

At speeds in excess of the sprag lift-off speed, no special lubrication is required; the freewheel functions maintenance-free.

When operating below the sprag lift-off speed, an oil lubrication of the specified oil quality must be provided.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.