PRODUCT

How about production technology for clutch bearing in WAXING?

2021-11-21

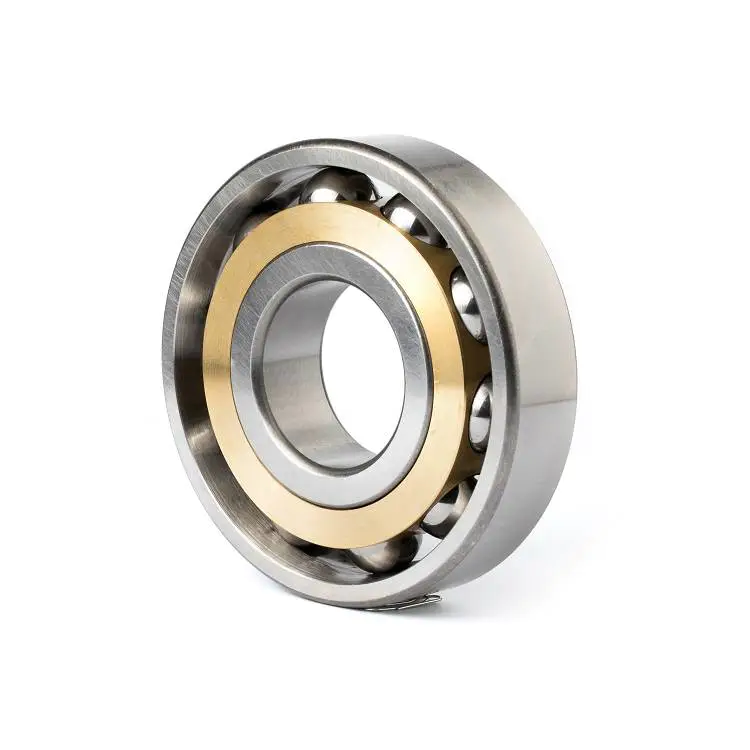

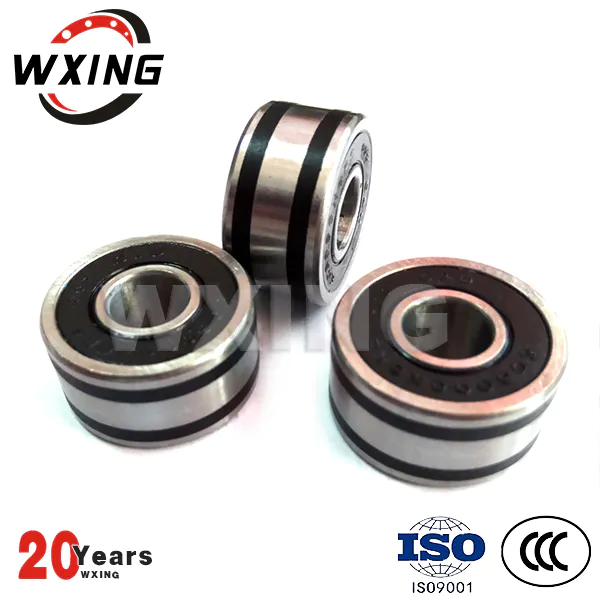

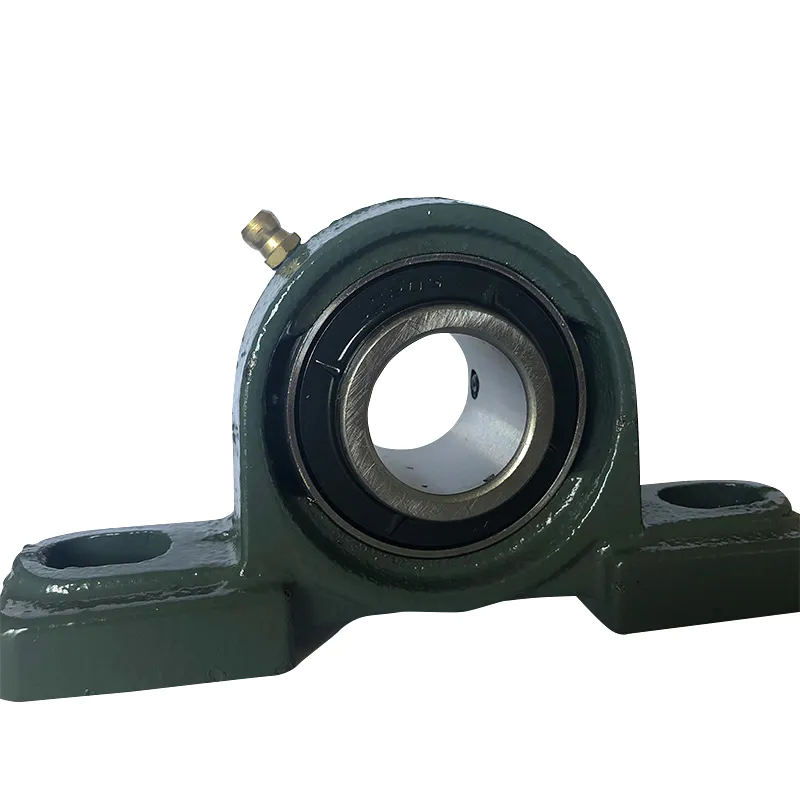

Zhejiang Waxing Electromechanical Co., Ltd has advanced production technology and superb manufacturing process for clutch bearing. Our first-class level of equipment, production technology as well as the operation and management ensure the product's first-class quality. We stick to the excellent material selection, advanced production technology application and strict environmental standards.

Zhejiang waxing electromechanical co.LTD., which is committed to corporating innovation, is a diversified enterprise group that focuses on the creativity, design and marketing of bearing. According to the material, WAXING's products are divided into several categories, and spherical roller bearing is one of them. During the Waxing thrust ball bearing size chart manufacturing process, diverse stages are involved. They mainly cover preparation for design (foot type collection), graphic design, pattern cutting, machining, and surface & edges trimming. Thanks to the high-grade steel ball, it stays quiet and smooth during high-speed running. A number of quality tests will be carried out to ensure that products meet industry quality standards. The well-selected ferrules of the product make sure no mounting error.

For the better development of Waxing, necessary enterprise culture will be more necessary. Check it!

Zhejiang waxing electromechanical co.LTD., which is committed to corporating innovation, is a diversified enterprise group that focuses on the creativity, design and marketing of bearing. According to the material, WAXING's products are divided into several categories, and spherical roller bearing is one of them. During the Waxing thrust ball bearing size chart manufacturing process, diverse stages are involved. They mainly cover preparation for design (foot type collection), graphic design, pattern cutting, machining, and surface & edges trimming. Thanks to the high-grade steel ball, it stays quiet and smooth during high-speed running. A number of quality tests will be carried out to ensure that products meet industry quality standards. The well-selected ferrules of the product make sure no mounting error.

For the better development of Waxing, necessary enterprise culture will be more necessary. Check it!

Custom message