The speed increaser of the wind turbine is installed at a high place and is difficult to maintain. Therefore, the life and reliability of the speed increaser bearings are very high. In recent years,

wind turbines have become larger and larger. In order to reduce the load on the tower, attempts have been made to make the generator cabin smaller and lighter. Therefore, the demand for

small bearings with high load capacity has further increased.

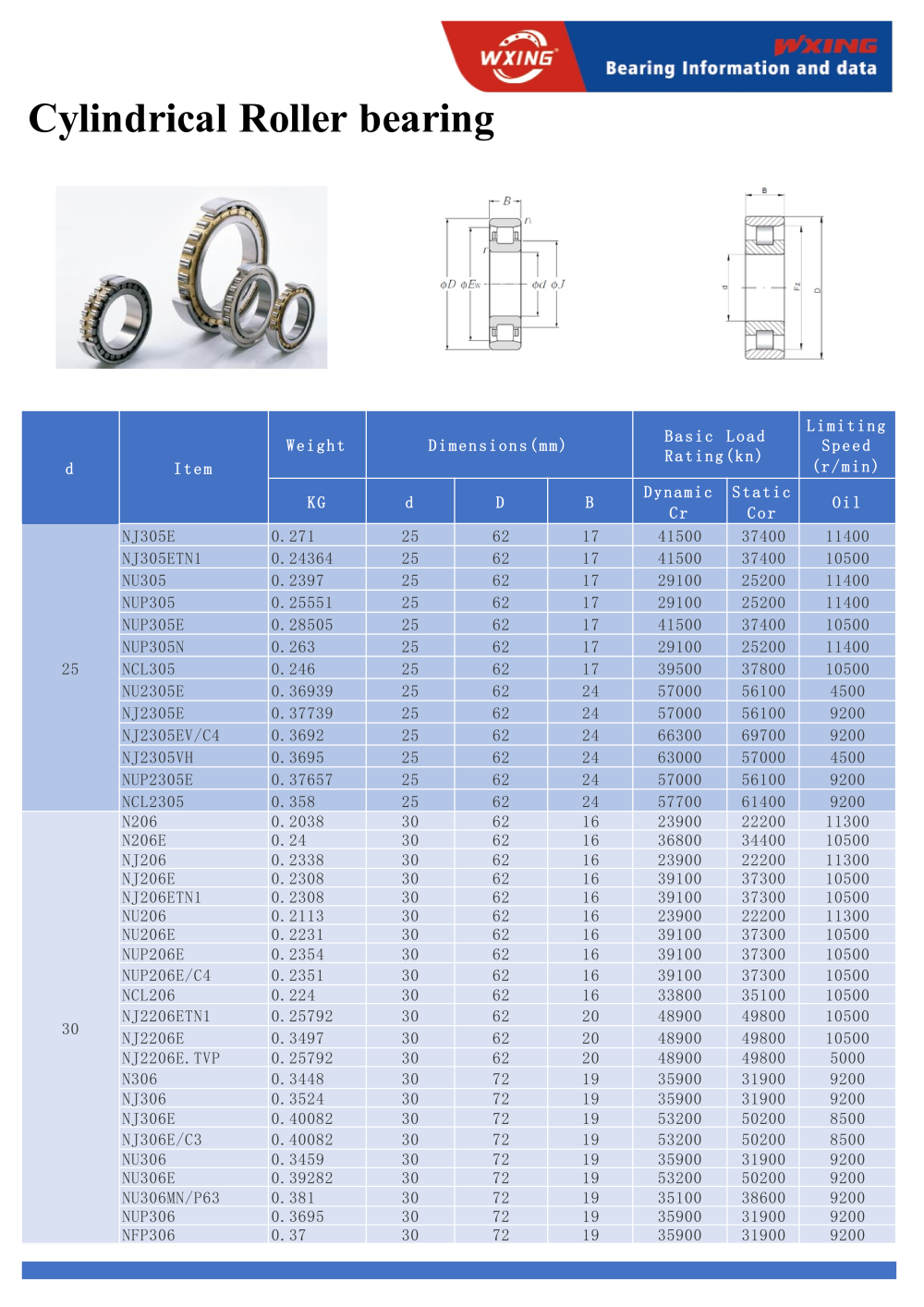

The high load capacity cylindrical roller bearing developed to meet this demand (as shown in Figure 1) uses rolling element spacers instead of cages, so the load capacity is increased without

The high load capacity cylindrical roller bearing developed to meet this demand (as shown in Figure 1) uses rolling element spacers instead of cages, so the load capacity is increased without

damaging the rotation performance, and the rated life reaches 1.5 times that of the original product. More than times.

Structure and characteristics of high load capacity cylindrical roller bearings:

The new product is designed with spacers made of resin material between the rollers to prevent the rollers from contacting each other. In addition, on the spacers that are independent of each other,

the tension caused by the clutch and separation of the rollers does not work, so the thickness can be reduced, thereby increasing the size and number of rollers.

By comparing the performance of the new product with the original product, the new product's high load capacity cylindrical roller bearing has the following advantages:

1. Long life

The size and number of rollers are optimized to increase the load capacity. The rated life of the bearing is more than 1.5 times that of the bearing with cage that has not changed in original size.

2. High speed

To prevent the rollers from contacting each other in a full complement roller bearing, it is best to optimize the shape and guide method of the spacer to achieve the same allowable rotation speed and

scratch resistance as a bearing with a cage.

3. Operability

Even if the inner ring is removed without causing the rollers to fall off, the inner ring and outer ring components can be installed separately, making installation on the machine easier.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.

CONTACT US

Consult our customers for surprise discounts.