1) Determination of manufacturing process method

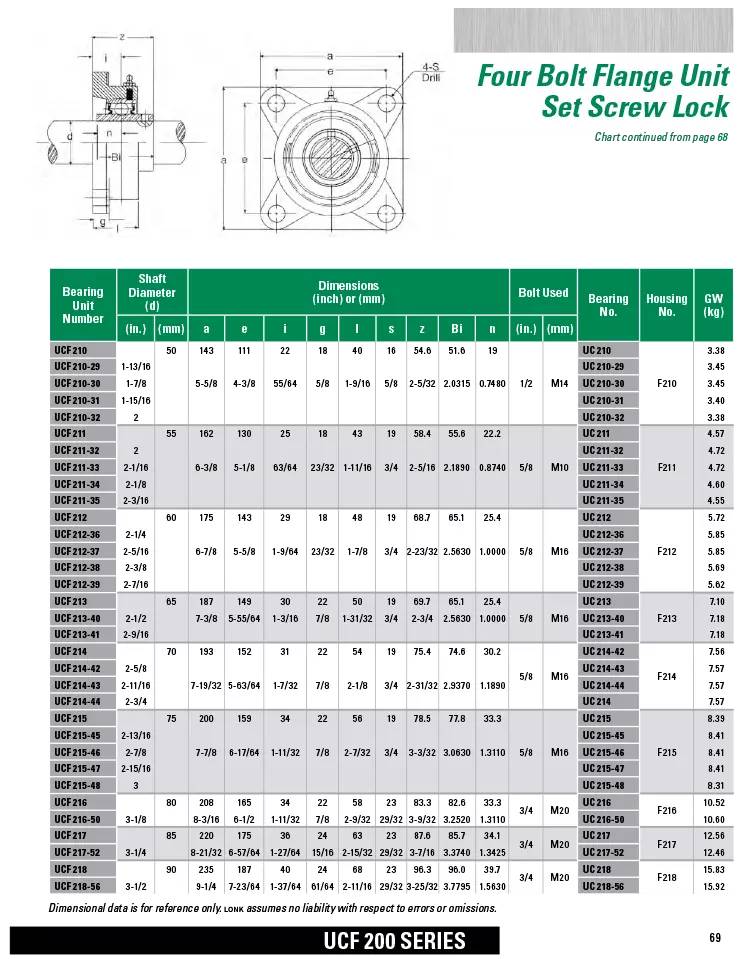

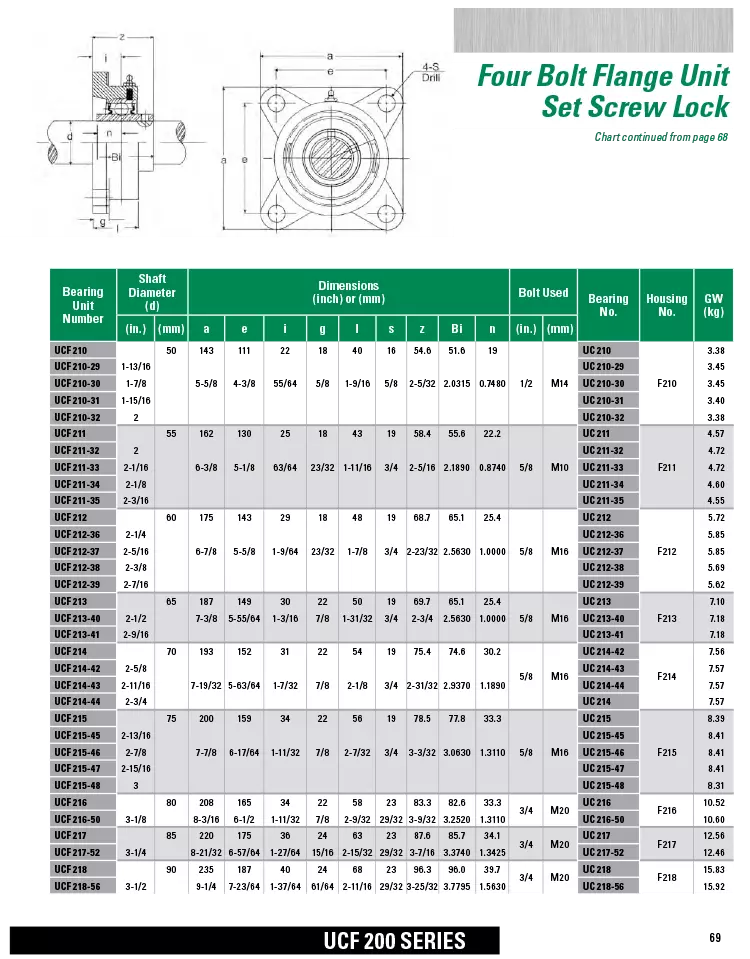

Analysis of the casting mechanism and its casting process. The bearing seat is used to clamp the bearing, thereby supporting the shaft and parts on the shaft.

The weight of the casting is about 10Kg

Part material is HT200

Outline size (215X80X146) mm

Production program: mass production

2) Because the casting is small, it is advisable to use a wet type that can be used as both a veil and a back veil.

3) Modeling methods: whole mold, loose block, two-box model modeling

4) Determination of parting surface

The entire shape of the bearing seat is used as the parting surface, and wood is used as the sand core of Φ62.5, and it is basically on a plane. Therefore, the entire shape of the bearing is selected as the parting surface, so that the entire cavity is in the lower mold, so The parting also facilitates the security of the pouring riser.

5) Determination of the position of the pouring riser

The casting is HT200, with a small volume shrinkage. However, the casting is a thick solid part, so attention must be paid to the occurrence of shrinkage defects. Therefore, the position and direction of the introduction of the ingate are very important. According to the structural characteristics of the casting, directional According to the solidification principle, the ingates should be introduced from both ends of one side of the base. This can also prevent the Φ62.5 sand mold from being damaged. The gate that resists the edge gap can reduce the contact hot spots between the gate and the casting. It can also avoid overheating of the thick middle part and shorten the solidification time, which is conducive to obtaining qualified castings. In addition, due to the good feeding effect of the edge gate, the casting does not need to be equipped with a feeding riser to prevent the occurrence of pores. , you can set a Φ8-Φ10mm air outlet riser position at the middle edge of the top.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.

CONTACT US

Consult our customers for surprise discounts.