1. Application of bearing materials in automobiles

As we all know, bearings are composed of four parts: outer ring, inner ring, rolling elements (ball, cylindrical, tapered or needle roller, etc.) and cage. Some have sealing rings. In addition to sealing rings and part of the cage, the rest The manufacturing material is mainly bearing steel.

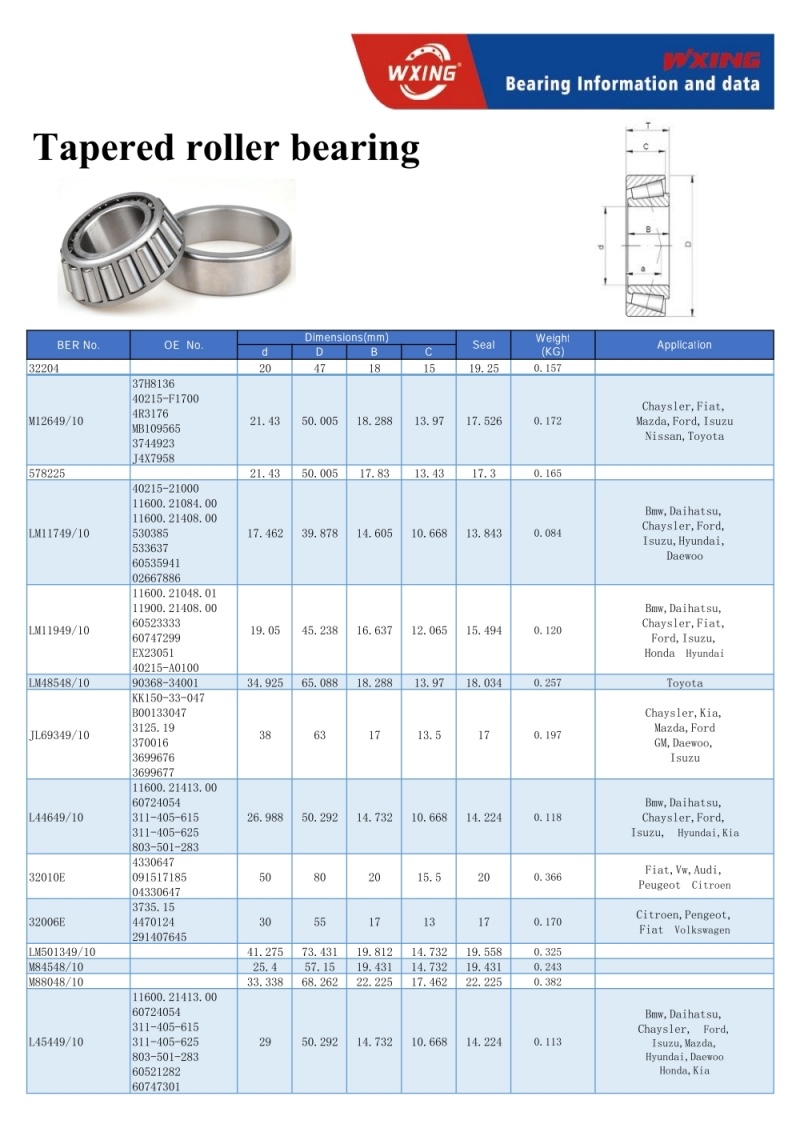

When selecting the type and model of automobile bearings, it is mainly based on the nature, direction, size of the load, the working environment of the actual location, as well as the requirements for the bearing's rigidity, limit speed, life, accuracy, etc., and is generally completed by the designer. Bearings are widely used in vehicles and vary with vehicle type, installation location and manufacturer, as shown in Figure 1.

The author has visited some important domestic automotive bearing suppliers, such as Shanghai Renben, Zhejiang Wanxiang Precision, Hubei New Torch, Changzhou Guangyang, Luoyang Dongsheng, Chongqing Yangtze, etc. The following only combines the automotive power system (alternator in the engine) , air conditioning electromagnetic clutch, tensioner pulley, idler pulley and other bearings), drive system (shaft teeth in the gearbox, differential, clutch and other bearings), wheel hub bearings and other related products are briefly introduced.

(1) Power system bearings

(1) Power system bearings

The engine is the heart of the car, continuously providing power to other components. The internal bearings were previously dominated by sliding bearings. Nowadays, most of them use sealed ball bearings on the premise of improving bearing performance. Figure 2 shows several typical bearings in engines.

The alternator bearing is a single-row sealed ball bearing, which is mainly affected by centripetal force. It is required to operate reliably when the speed exceeds 2000r/min and the temperature exceeds 180°C. The rings and rolling elements are made of high-purity GCr15, and the hardness after heat treatment is required to be 58 ~64HRC, the cage is generally made of nylon PA46, and the sealing ring is generally made of acrylic rubber ACM. The reference standard is JB/T8167-2006.

The electromagnetic clutch bearing of the air-conditioning compressor is a double-row angular contact ball bearing. The outer ring rotates. The speed of the air-conditioning pulley can reach 7000~13000r/min. The maximum temperature is 160°C. The material is the same as above. The cage is changed from a part of an ordinary single spherical pocket. Cylindrical surface, the reference standard is JB/T10531-2005.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.

CONTACT US

Consult our customers for surprise discounts.