Structure:

Type:

Applicable Industries:

Bore Size:

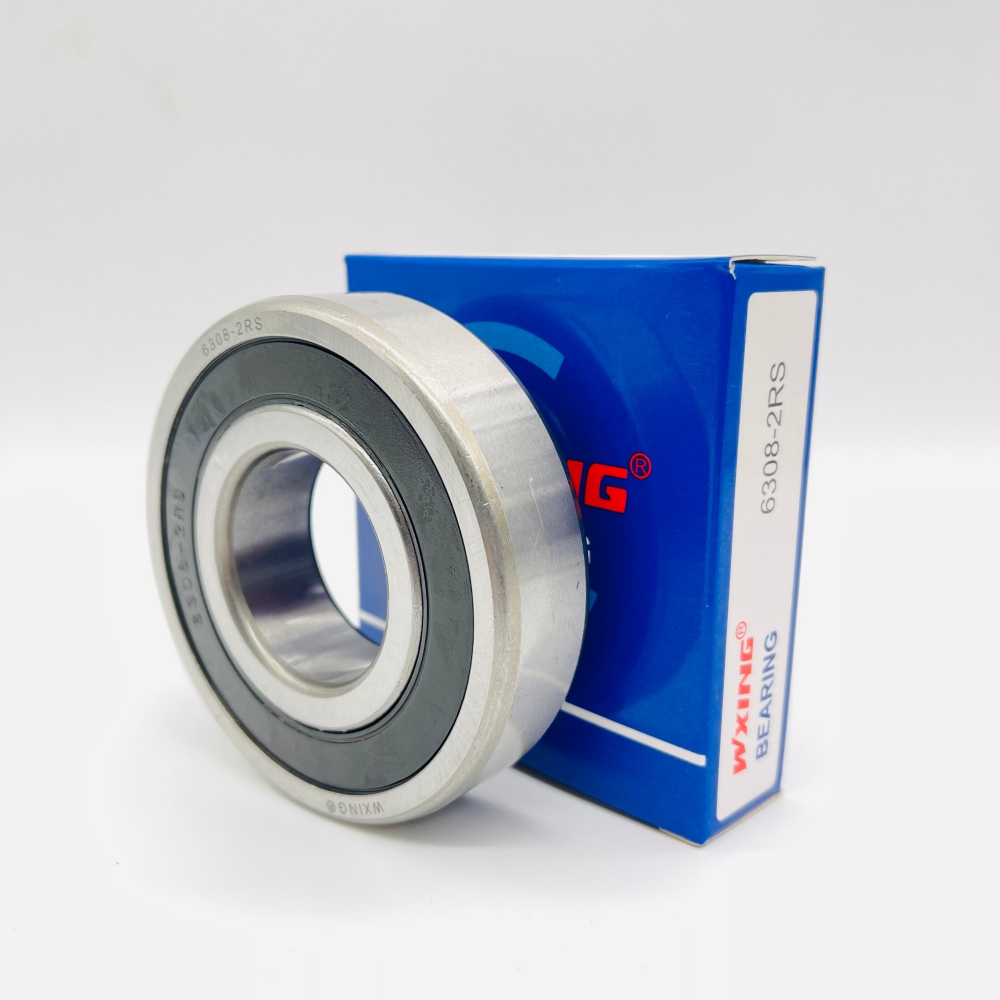

Model Number:

Precision Rating:

Seals Type:

Number of Row:

Place of Origin:

Material:

Cage:

Technology:

Main market:

Name:

Lubrication:

Service:

Certificate:

Supply Ability:

100000 Piece/Pieces per Month

The friction mechanism of bearings is significantly different from other bearings. Friction force mainly depends on factors such as radial load, swing frequency, number of swings, swing angle, contact surface temperature and surface roughness. Generally, when deep groove ball bearings are in motion, the inner and outer rings slide relative to each other and generate friction, and the friction force is relatively large; while in other bearings, when the lining layer and the inner ring or outer ring slide relative to each other, friction is generated, and the friction coefficient is smaller. Research shows that under the same conditions, the friction coefficients of skf bearings of different materials are significantly different in the lining materials.

As bearings continue to develop, their wear mechanisms and forms are also changing. During the working process, generally lubricated bearings cause the continuous loss of material on the working surface layer of the bearing due to the relative sliding of the inner and outer rings, causing the bearing to not work properly. The main forms of wear include adhesive wear, abrasive wear and corrosive wear. The wear of deep groove ball bearings is due to the relative sliding between the lining and the inner and outer rings during operation, which causes the lining to fall off, tear, extrusion and other failure modes, causing the bearing to not work properly.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.

CONTACT US

Consult our customers for surprise discounts.