PRODUCT

How are materials used by WAXING for producing clutch bearing?

2021-11-21

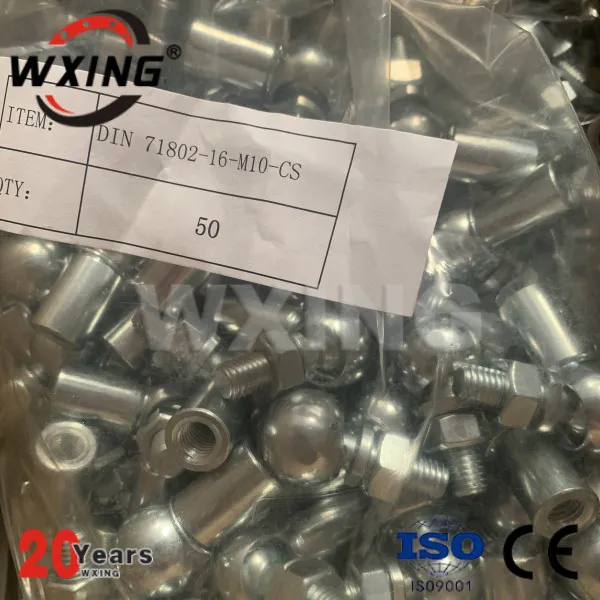

Our responsibility for quality starts with the selection of materials. We have a responsibility to make sure our suppliers take care of their materials. We use industry-wide guidelines to assess their materials and select only the best. And before we put the raw materials into production, we have a materials testing procedure. Our expert team will carefully test the materials to ensure that they are suitable for processing and meet the safety and quality requirements. Our strict quality control over raw materials ensures you only get high-quality and high-performing clutch bearing.

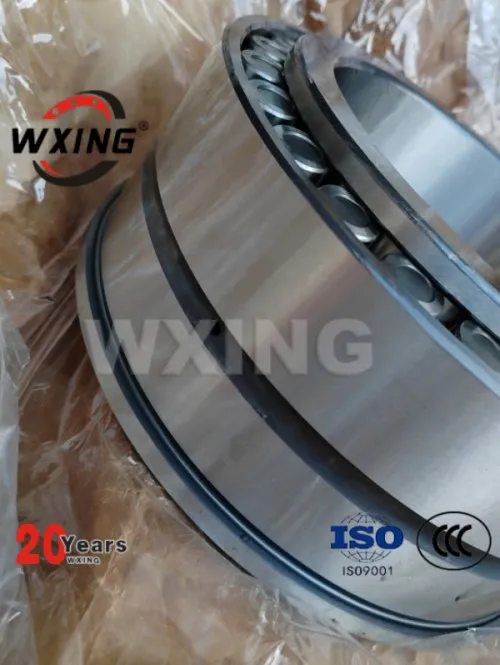

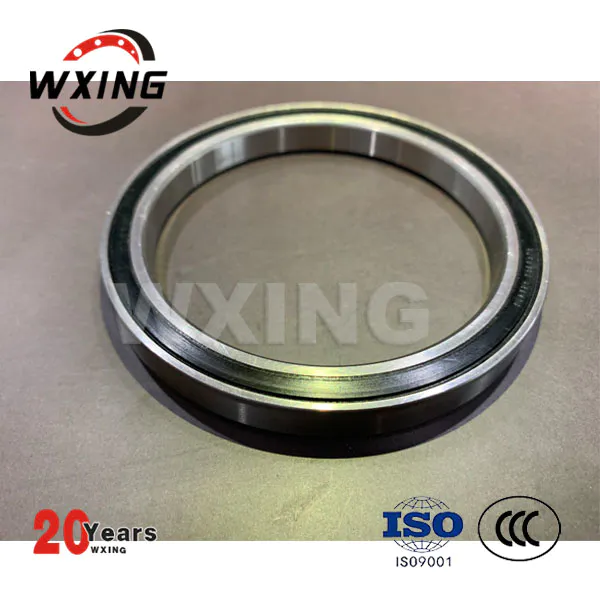

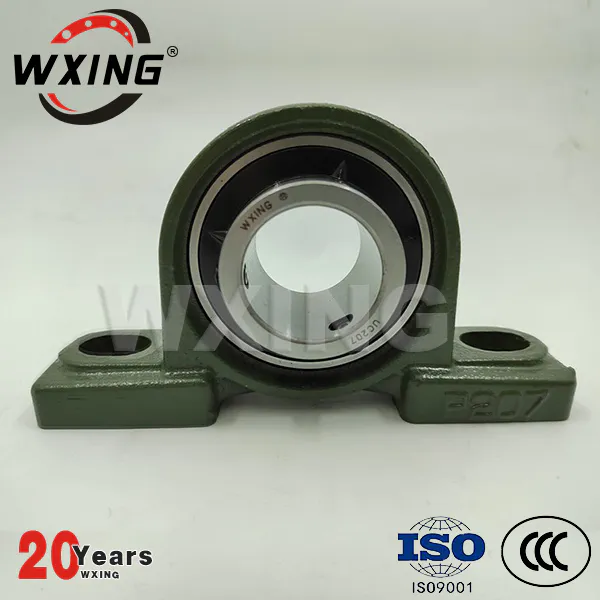

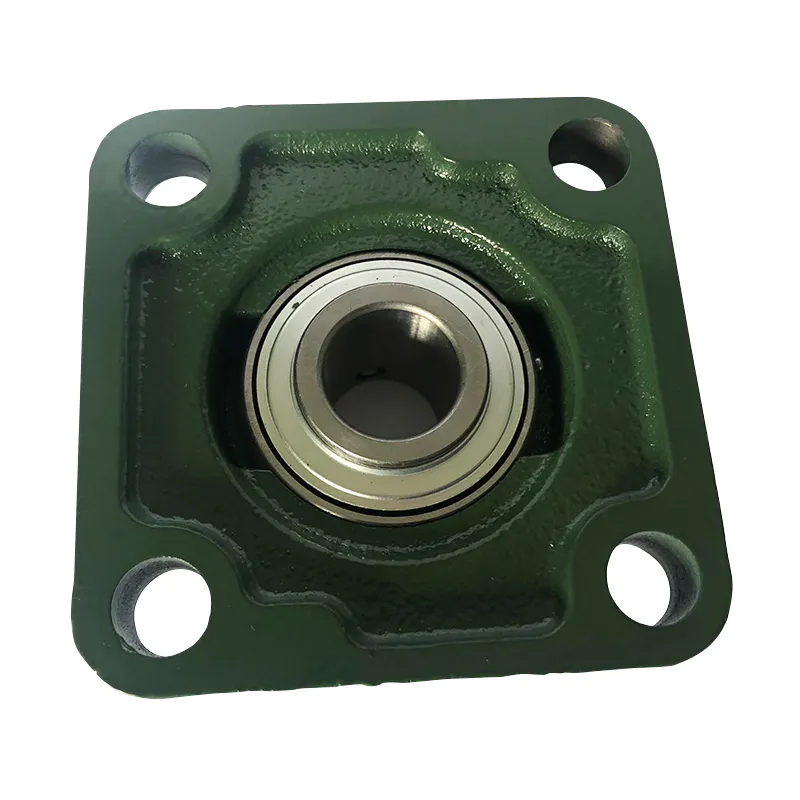

Zhejiang waxing electromechanical co.LTD. has become the China's largest linear bearings enterprise and production base. According to the material, Zhejiang Waxing Electromechanical Co., Ltd's products are divided into several categories, and pillow block bearing is one of them. The inspections of Waxing double row angular contact bearing include different aspects. They cover thickness tolerance, flatness, longitudinal & torsional stiffness, tear strength, and slip resistance. It has low torque capacity when starting and running. Conduct overall quality control to ensure that products meet all relevant quality standards. The roller and thrust bearing are separable, making it easy to conduct maintenance and inspection.

Waxing upholds the idea that enterprise culture plays an important role in the growth of a company. Please contact us!

Zhejiang waxing electromechanical co.LTD. has become the China's largest linear bearings enterprise and production base. According to the material, Zhejiang Waxing Electromechanical Co., Ltd's products are divided into several categories, and pillow block bearing is one of them. The inspections of Waxing double row angular contact bearing include different aspects. They cover thickness tolerance, flatness, longitudinal & torsional stiffness, tear strength, and slip resistance. It has low torque capacity when starting and running. Conduct overall quality control to ensure that products meet all relevant quality standards. The roller and thrust bearing are separable, making it easy to conduct maintenance and inspection.

Waxing upholds the idea that enterprise culture plays an important role in the growth of a company. Please contact us!

Custom message