Product Description

| Product Name | NK Series Needle Bearing 60x90x28mm Roller Bearing |

| Size | 60x90x28 mm |

| Precision | P0, P2, P4, P5, P6 |

| Vibration Level | V1, V2, V3, V4 |

| Clearance | C2, C3, C4, C5 |

| Hardness | 59-63 HRC |

| Material | Gcr15, Gcr15SiMn, Chrome steel, ceramic, stainless steel |

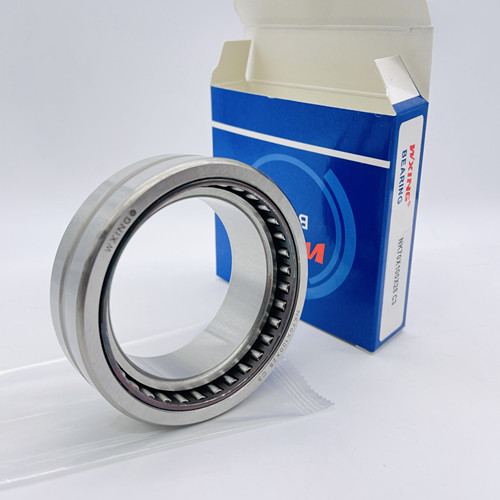

Products Show

Needle bearings are a special type of roller bearing that use elongated cylindrical rollers that resemble needles. The rollers of ordinary roller bearings are only slightly longer than their diameter, but the rollers of needle roller bearings are usually at least four times longer than their diameter.

Needle bearings utilize small cylindrical rollers called needles to reduce friction between moving parts. The needle roller is the load-bearing part of the needle roller bearing. Depending on the bearing design, they are located between two races, between a race and a shaft, or between a shaft and a housing.

1. Advantages of needle roller bearings

Needle roller bearings have a large rolling element bearing surface but a small diameter. Specifically, Mark's Standard Handbook of Mechanical Engineers defines a needle roller bearing as "a roller bearing in which the length of the rollers is at least four times its diameter." The surface area of the rollers and the large number of rolling load-bearing elements provide needle bearings with excellent load-carrying capacity and stiffness.

Most radial needle roller bearings are designed to accommodate axial forces exceeding 5% of the radial load. Those used in radial applications have rollers parallel to the axis. Thrust bearings, that is, bearings intended for axial loads, contain rollers whose shafts are perpendicular to the shaft and extend radially from that shaft.

All needle bearings require some type of lubricant to help dissipate heat and reduce friction. The amount of friction depends on the load being carried, the type and size of the needle bearing, the rotational speed of the bearing, and the properties of the lubricant used. Needle bearings, especially those with outer rings made of high-strength steel, also dampen shock and vibration.

2. Optimal needle bearing implementation depends on several factors

Needle bearings are designed to operate under minimal load. Failure to meet this quota may damage the raceways due to low roller inertia. Furthermore, needle roller bearings are generally not suitable for static loads. Such loads can damage the roller elements. This includes applications where the bearing rotates at less than 10 rpm, oscillates slowly, or may experience a static point.

1. The working temperature is the temperature range in which the bearing can be used. At low temperatures, the viscosity of the lubricating oil increases, requiring a higher minimum load.

2. The reference speed is the speed at which heat dissipation and heat generation are balanced.

3. The speed limit is the maximum speed at which the bearing is designed to operate. It depends on: the strength of the bearing cage, the quality of lubrication, centrifugal and rotary forces, the precision of bearing manufacturing and the characteristics of the lubricant.

2. How to measure needle roller bearings?

Measuring Bearings: Most bearings are measured in three ways, inside diameter or (ID), outside diameter or (OD) and width or (W). It is important to note that our bearings are measured in the following order: Inside Diameter (ID) x Outside Diameter (OD) x Width (W).

3. Type and size of needle roller bearings

Needle roller bearing models are 4002 size 17, 4003 size 48, 4004 size 22, 4005 size 22, 4006 size 25.

Needle Roller Bearing Standard

The accompanying criteria may be helpful when considering needle roller bearings.

ASTM F2162 - Standard Specification for Bearings, Rollers, Needle Rollers: Drawn Cup, Full Complement, No Cone, Open and Closed Ends, Standard Type

ASTM F2163 - Standard Specification for Inner Rings, Bearings: Needle Roller Bearings with Drawn Outer Rings

ISO 281 - Rolling bearings - Dynamic load ratings and rating life

ISO 3031 - Roller bearings - Axial needle roller and cage assemblies, thrust washers - Boundary dimensions and tolerances

ISO 3096 - Rolling bearings - Needle rollers - Dimensions and tolerances

4. Application of Needle Roller Bearings

Needle roller bearings are used in a variety of applications such as radial piston pumps, automotive steering and braking systems, power tools, transmissions, engines, valve trains, copiers, fax machines, outboard motors, and lawn trimmers.

More types of needle roller bearings:

You may also like these ones:

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.

CONTACT US

Consult our customers for surprise discounts.