PRODUCT

How much will it cost for clutch bearing production?

2021-11-30

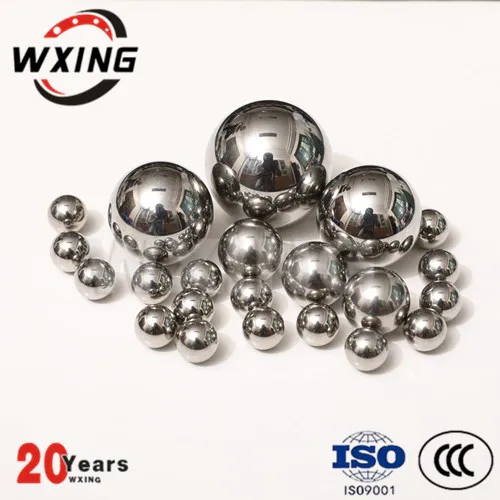

One of the biggest challenges that the clutch bearing manufacturing industry is facing is cost. All manufacturers are working hard to keep the prices down and not sacrifice quality. In global manufacturing, the cost depends on many factors. What Zhejiang Waxing Electromechanical Co., Ltd can share is the most important factors in determining the cost of a production project here in our company, they are the materials used, the size of the product, the manufacturing process used, the required quantity, the tool requirements, etc. And how much it will cost to finish your project will depend on your specific requirements.

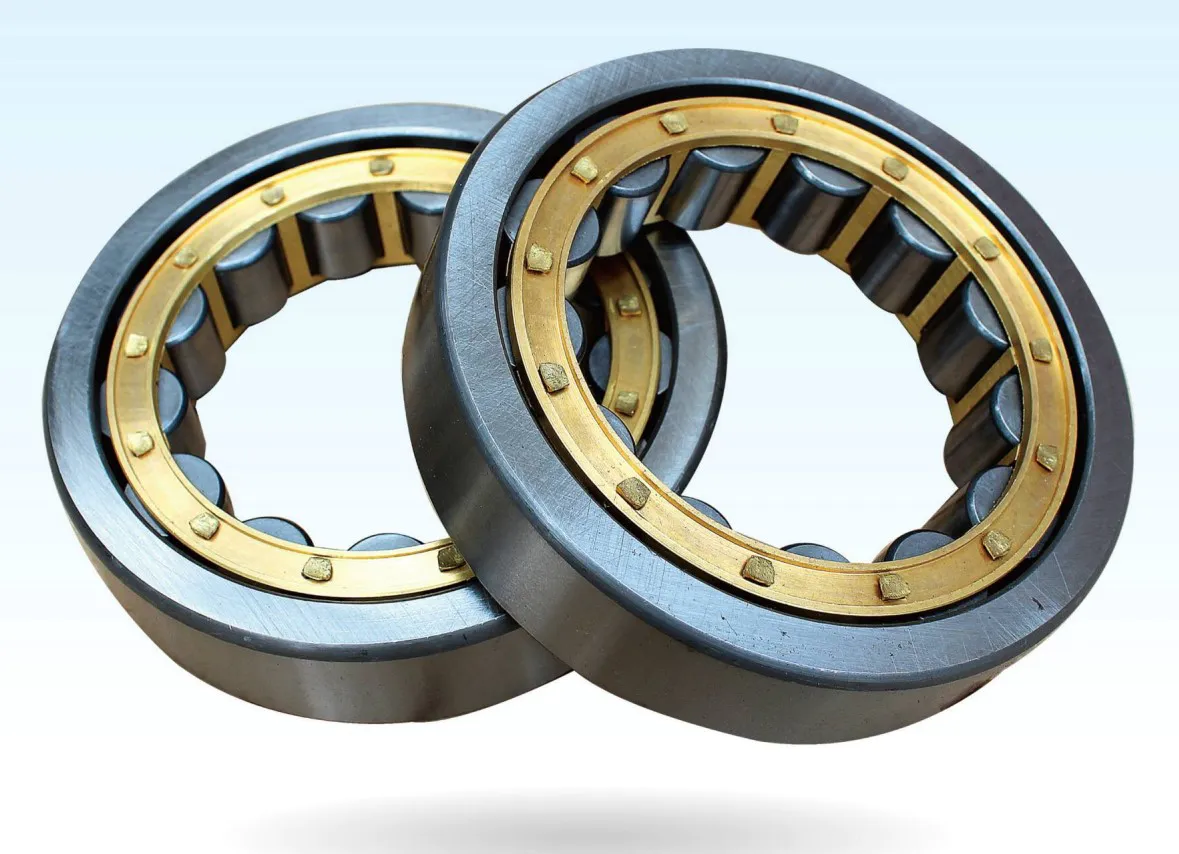

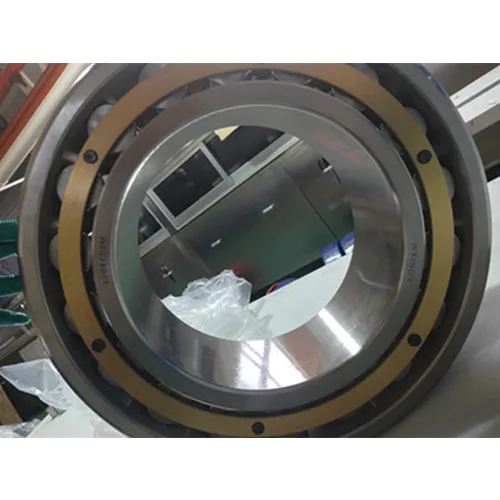

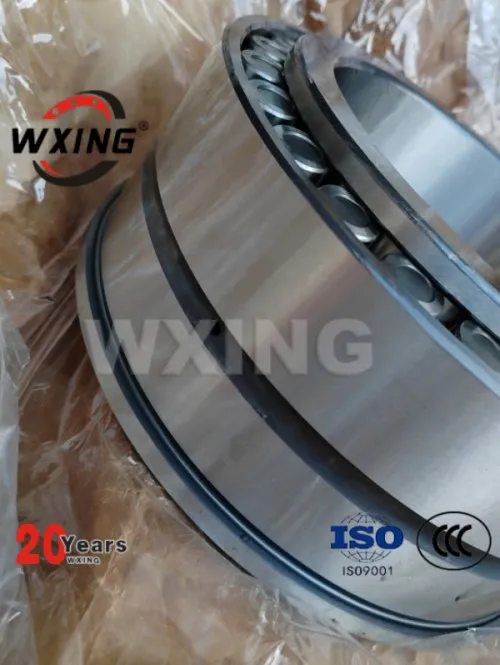

Zhejiang waxing electromechanical co.LTD. currently has a research and development center and a large-scale production base. According to the material, WAXING's products are divided into several categories, and angular contact ball bearing is one of them. During the Waxing cylindrical roller manufacturing process, diverse stages are involved. They mainly cover preparation for design (foot type collection), graphic design, pattern cutting, machining, and surface & edges trimming. Adopting ultra-clean steel, the product has obtained an extended bearing life. The product has been inspected in conformity with international quality standards. The product requires easy maintenance, saving a lot of manual labor.

Waxing is a specialized needle bearing supplier which is very ambitious. Inquiry!

Zhejiang waxing electromechanical co.LTD. currently has a research and development center and a large-scale production base. According to the material, WAXING's products are divided into several categories, and angular contact ball bearing is one of them. During the Waxing cylindrical roller manufacturing process, diverse stages are involved. They mainly cover preparation for design (foot type collection), graphic design, pattern cutting, machining, and surface & edges trimming. Adopting ultra-clean steel, the product has obtained an extended bearing life. The product has been inspected in conformity with international quality standards. The product requires easy maintenance, saving a lot of manual labor.

Waxing is a specialized needle bearing supplier which is very ambitious. Inquiry!

Custom message