How to measure and install the dimensions of angular contact bearings

Take a single set of angular contact ball bearings as an example;

The measurement method of outer diameter and inner diameter is the same as that of single row deep groove ball bearings. The width of angular contact deep groove ball bearings is called the assembly height;

AC contact type: Taking the big end as the base, the preload force acts on the big end surface of the outer ring, and the actual force is on the other side of the inner ring; conversely, taking the big end as the base, the preload force acts on the inner ring On the other end face, the actual force is exerted on the large end face of the outer ring.

BM contact type: similar to the above situation.

Characteristics and uses of angular contact ball bearings:

Angular contact ball bearings have a high limit speed and can bear both radial and axial loads, as well as pure axial loads. Their axial load capacity is determined by the contact angle and increases with the increase of the contact angle.

Single row angular contact ball bearings can only bear axial load in one direction. When bearing radial load, additional axial force will be caused, and corresponding reverse load must be applied. Therefore, this type of bearing is generally used in pairs. Double row angular contact ball bearings can withstand large combined radial and axial bidirectional loads and moment loads, mainly radial loads. They can limit the bidirectional axial displacement of the shaft or shell, and the contact angle is 30 degrees.

Angular contact ball bearings installed in pairs can withstand combined radial and axial bidirectional loads, mainly radial loads, and can also bear pure radial loads. The tandem configuration can only bear axial loads in one direction, while the other two configurations can bear axial loads in either direction. This type of bearing is generally submitted to the user in pairs selected by the manufacturer. After installation, there is preload interference, and the ferrule and steel ball are in an axial preload state, thus improving the rigidity and rotation of the entire set of bearings as a single support. Accuracy.

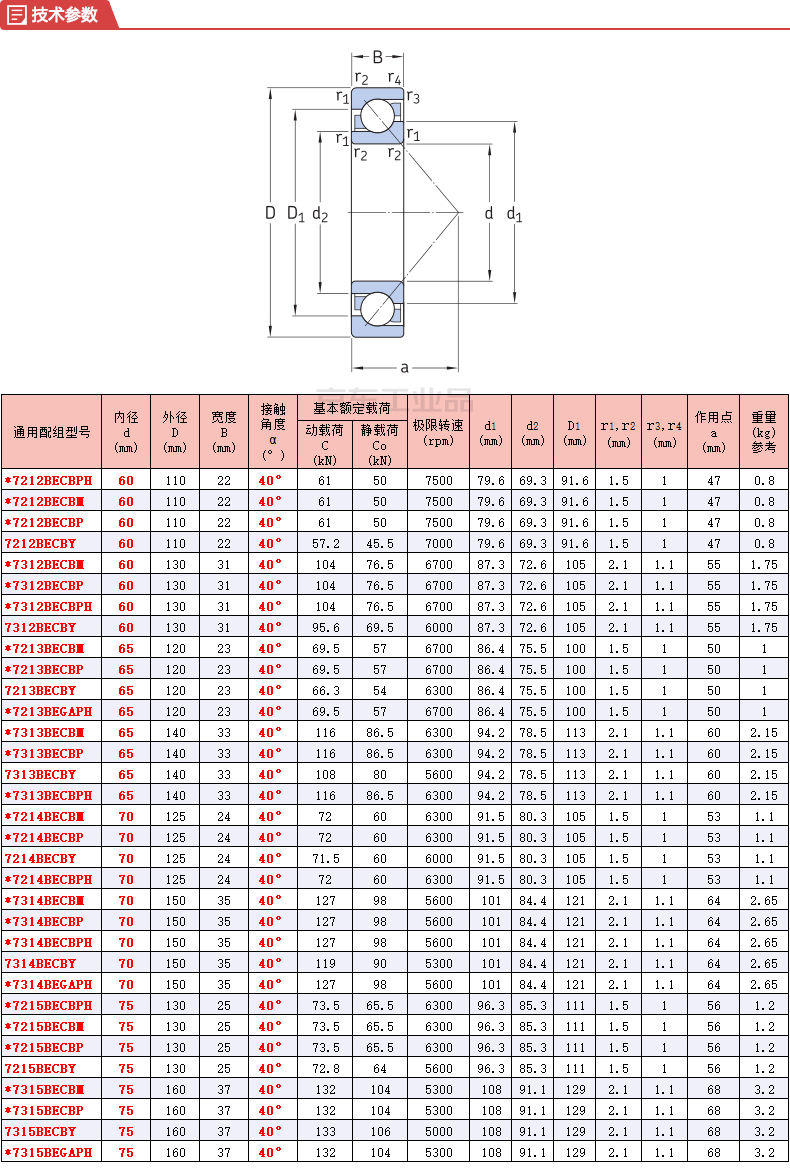

Specific classification and model comparison:

1. Angular contact ball bearing with a=15o (70000 C type)

2. Angular contact ball bearing with a=25o (70000 AC type)

3. Angular contact ball bearing with a=40o (70000 type B)

4. High-speed sealed angular contact ball bearing with a=15o (B70000 C-2RZ type)

5. High-speed sealed angular contact ball bearing with a=25o (B70000 AC-2RZ type)

6. High-speed sealed angular contact ceramic ball bearing with a=15o (B70000 C-2RZ/HQ1 type)

7. High-speed sealed angular contact ceramic ball bearing with a=25o (B70000 AC-2RZ/HQ1 type)

8. Back-to-back pairs of double angular contact ball bearings [70000 C (AC, B)/DB type]

9. Face-to-face paired double angular contact ball bearings [70000 C (AC, B)/DF type]

10. Series paired double angular contact ball bearings [70000 C (AC, B)/DT type]

11. Double row angular contact ball bearings with ball installation gaps (0000 type a=30o)

12. Double row angular contact ball bearing without ball installation gap (0000 A type a=30o)

13. Double row angular contact ball bearing with dust cover on one side (0000 A-Z type a=30o)

14. Double row angular contact ball bearings with dust covers on both sides (0000 A-2Z type a=30o)

15. Double row angular contact ball bearing with sealing ring on one side (0000 A-RZ type a=30o)

16. Double row angular contact ball bearings with sealing rings on both sides (0000 A-2RZ type a=30o)

17. Four-point contact ball bearing (QJ type a=35o)

They are used in pairs to increase or balance the bearing force. According to the direction of the axial force, you can choose DB back-to-back installation, DF face-to-face installation, or DT series installation. For machine tool spindles, triple installation, quadruple installation, or even There are five-way installations. Normally, the axial load is bidirectional, and there is rarely a purely unidirectional axial load, so angular contact ball bearings are installed in pairs. Installation in pairs can increase the radial load capacity on the one hand, and provide the bearing load capacity more specifically to increase the toughness of the spindle on the other hand.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.

CONTACT US

Consult our customers for surprise discounts.