CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

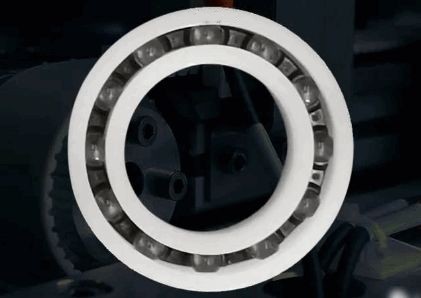

1 Development prospects of plastic bearings

At present, most equipment customers still struggle between plastic and metal bearings when choosing bearings for their equipment. After all, when plastic bearings have not been produced, metal bearings have always been the traditional material choice, and many people are still reluctant to give up the choice of metal materials. But so far, the performance of plastic bearings is getting better and better in the future.

2 Plastic bearing materials and their advantages

In fact, the production cost of plastic is lower than that of metal bearings, and the variety of plastic materials is increasingly abundant. Used in many industries, the most common plastic materials are nylon, PTFE, polyethylene and PEEK.

The versatility, economy and cleanliness of plastic bearings. There are many low-cost materials available for a variety of applications. Plastic bearings are typically made from thermoplastic alloys with a fibrous matrix and solid lubricants that provide excellent strength and a consistently low coefficient of friction.

3 What are the good properties of plastic bearings?

(1) Self-lubricating

Plastics, by their very nature, lubricate bearings, reduce start-up delays and keep areas clean. The tiny bits of the bearing wear out and act to lubricate the bearing in the first place, but the change in the bearing itself is negligible. This also makes plastic bearings more suitable for food applications, as the FDA strictly restricts the use of lubricants in food production machinery. Also, while dust and other particles can stick to the lubricant and create a layer of dirt, with plastic bearings, any particles will simply become embedded in the bearing without affecting performance.

(2) Operation at low and high temperature

Plastic bearings can operate continuously at any temperature between -4°C and 260°C and can withstand peak temperatures up to 600°F. Plastic bushings can be as strong as metal bushings but with thinner walls, typically 0.0468"-0.0625" thick. Thinner walls are better at dissipating heat, resulting in a larger operating range and less wear. Additionally, thin walls are lighter and less likely to deform, making them suitable for applications where weight is an issue.

(3) Environmental performance

Plastic bearings are more fuel efficient due to their light weight. Plastic bearings do not require additional coatings or additives to produce the same results as metal parts that are often supplemented with harmful elements. Furthermore, plastic production requires only about 10-15% oil compared to the same amount of aluminum or steel.

(4) Good chemical resistance

Plastic bearings are generally more resistant to a variety of chemicals and substances than metal bearings, resisting the scratches and wear that occurs with metal bearings. This helps keep their coefficient of friction low, moving smoothly with minimal disturbance.

(5) Maintenance-free bearings

By choosing the correct plastic for the environment in which it will be used, the bearing will resist corrosion over time. Once installed, the plastic bearings have a long service life and do not need to be replaced. Corrosion can cause metal bearings to freeze in place, making them nearly impossible to remove without cutting them out. Plastic bearings are easy to remove.

(6) Low price of plastic

Many plastics are cheaper than metals. So plastic bearings and plastic bushings can reduce costs by up to 25%

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.