Type:

Bore Size:

Brand Name:

Outside Diameter:

Model Number:

Precision Rating:

Seals Type:

Number of Row:

Place of Origin:

Product name:

Material:

Size:

Height:

Weight:

Driving Torgue:

OEM:

Delivery time:

Stock:

Selling Units:

Single item

Single package size:

19X18X10 cm

Single gross weight:

0.003 kg

Package Type:

Plactic bag + Carton Box

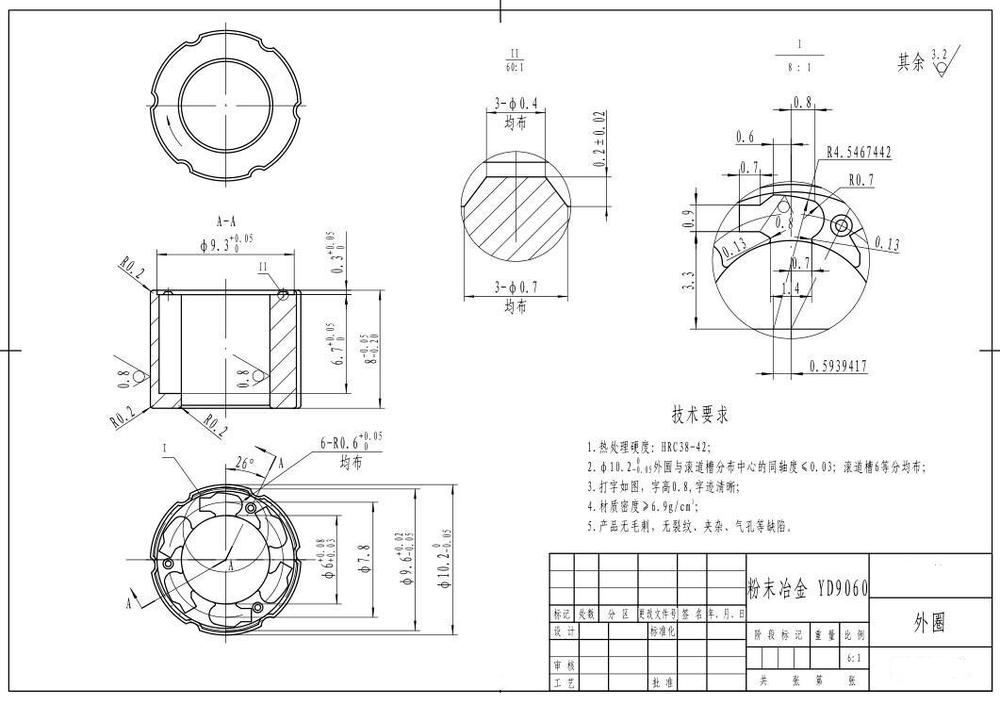

OWC1016 Powder Metallurgy One Way Needle Roller Bearing

Features of OWC1016 Needle Bearing

OWC is a one way needle clutch which applied flexibly of the technology of small bearings ,and

make the structure more compact as well as higher performance.

Material of OWC1016 Needle Bearing

Outer ring: is made by sintered metal

Spring: is made by stainless steel

Product name | Needle Roller Bearing |

Model | OWC1016 |

Material | ST14 |

Shaft diameter | 10mm |

lnner diameter | 10mm |

Outer diameter | 16mm |

Weight | 3g |

Application | Fishing machinery, ATM, Counting machine, Printer, copier, etc |

Package | Roller Pack, Carton box , Pallet or Customized |

Payment terms | TT. L/C, D/A,D/P,Western Union, Paypal |

Delivery time | 2-4 days for the sample, 7 days for big order |

Catalogue of OWC1016 Needle Bearing for your choice

GXRZ series are clockwise rotation

GXLZ series are anticlockwise rotation

| Shaft Dia. | Model | Weight | Size (mm) | Driving Torque | ||

| mm | g | Inner Dia. | Outer Dia. | Height | ( Nm ) | |

| 4 | OWC406GXRZ | 1.6 | 4 | 8 | 6 | 2.5 |

| 4 | OWC408GXRZ | 1.8 | 4 | 8 | 8 | 3.1 |

| 4 | OWC410GXRZ | 1.8 | 4 | 10 | 5.4 | 2.8 |

| 5 | OWC511GXRZ | 2 | 5 | 11 | 5.4 | 3.5 |

| 6 | OWC612GXRZ | 2.3 | 6 | 12 | 5.4 | 5.2 |

| OWC612GXLZ | 2.3 | 6 | 12 | 5.4 | 5.2 | |

| 8 | OWC814GXRZ | 2.8 | 8 | 14 | 5.4 | 6.1 |

| 8 | OWC814GXLZ | 2.8 | 8 | 14 | 5.4 | 6.1 |

| OWC812GXRZ | 2.8 | 8 | 12 | 5 | 5.8 | |

| 10 | OWC1016GXRZ | 3 | 10 | 16 | 5.4 | 9.5 |

| 10 | OWC1016GXLZ | 3 | 10 | 16 | 5.4 | 9.5 |

| 6 | OWC612-8.4 | 2.35 | 6 | 12 | 8.4 | 6.8 |

| 6 | OWC610GXRZ | 2.38 | 6 | 10.2 | 8 | 4.6 |

| 6 | OWC614-7 | 2.1 | 6 | 14 | 7 | 6.6 |

| 6 | OWC720 | 2.5 | 6 | 12.7 | 7.5 | 7.3 |

| 6 | OWC178 | 3 | 6 | 10.2 | 15 | 7.3 |

| 8 | OWC816-7 | 2.6 | 8 | 16 | 7 | 7.5 |

| 8 | OWC812 | 3 | 8 | 12.7 | 7.3 | 6.8 |

| 8 | OWC816-5.5 | 3.5 | 8 | 16 | 5.5 | 8.2 |

| 8 | OWC816-6.2 | 3.8 | 8 | 16 | 6.2 | 8.8 |

| 10 | OWC1016-8 | 3.35 | 10 | 16 | 8 | 9.7 |

| 10 | OWC1019GXLZ | 8.5 | 10 | 19 | 11 | 19.8 |

|

In order to meet the standards in the textile industry, Waxing sealed needle bearings is produced under strict quality control. A number of quality control checks and tests such as size fitting, colorfastness, and color matte are carried out. Its temperature control system ensures uniform temperature ruing different segments for plastic molding

Waxing needle bearing has to go through a wide range of production processes, including material washing, CNC cutting, welding, plating, chemical spraying, and so on. It meets the standards of 100-grade dust-free workshop

In the manufacture of Waxing needle bearing, a range of techniques have been used, from CAD design, 3D imaging, model manufacturing, to final assembly. The product features high-precision cutting on materials of various sizes

Before the delivery of Waxing sealed needle bearings, it undergoes a strict brightness test. It is analyzed and screened by brightness analyzer to eliminate unqualified one. Japan MITSUBISHI servo motor is adopted for delivering different pulling force

The manufacture of Waxing needle bearing involves the following stages: medical material and processes specification, vendor selection, detailed part design, software fine-tuning and testing, failure mode analysis, and tolerance analysis. The product saves human labour effectively by eliminating the adjustment of mold structure

Our quality analysts conduct regular checking of the product on various quality parameters. The product saves human labour effectively by eliminating the adjustment of mold structure

Product Message

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Chat Online

编辑模式下无法使用

Leave Your Message

inputting...

Thanks for your message, we will reply you soon in our working time!

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly. | ||||||