Needle beaing

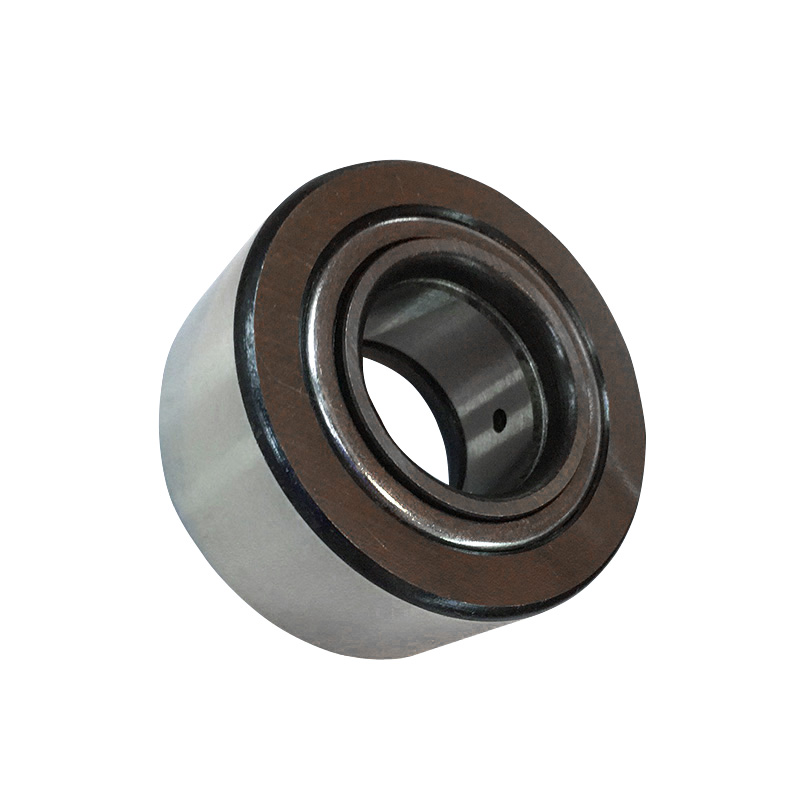

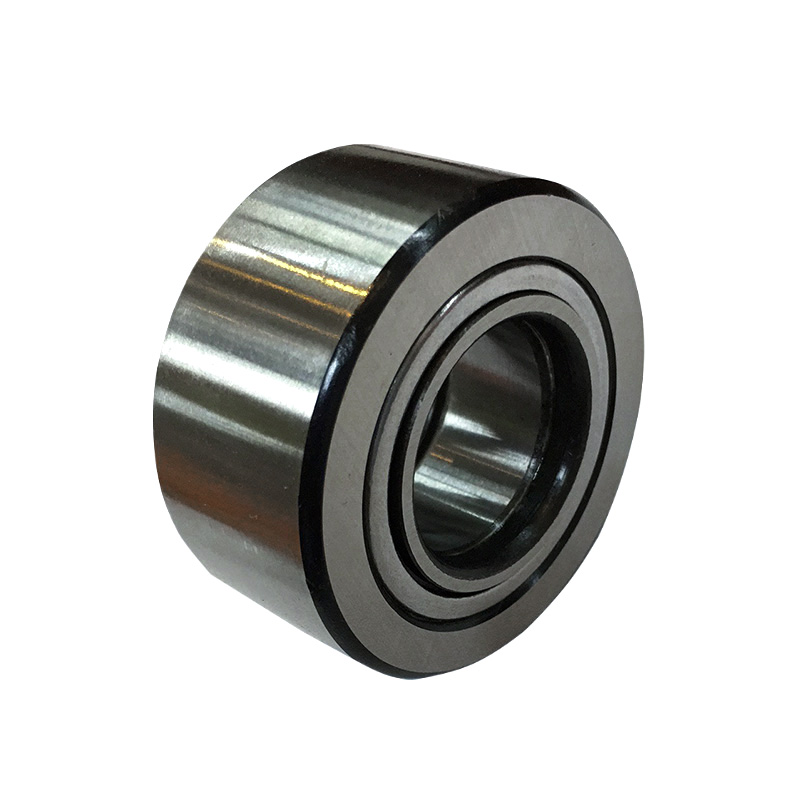

Needle roller bearings are essentially cylindrical roller bearings except that their cylindrical rollers have a length 3 to 10 times their diameter (versus a length less than 3 times their diameter). Needle bearings are also essentially bearings that utilize small & cylindric rollers. Therefore, the ratio of the bearing outside diameter to the inscribed circle diameter is small, and they have a rather high radial load capacity. Even though they have a low cross section, needle roller bearings have a high radial load capacity and are exceptionally apt for bearing applications where radial space is limited.

There are numerous types available, and many have no inner rings. The drawn-cup type has a pressed steel outer ring and the precision (solid) type has a machined outer ring. There are also cage-and-roller assemblies without rings. Most bearings have pressed steel cages, but some are without cages.

Drawn cup needle roller bearings have a drawn outer shell serving as a raceway for the rollers and are installed with a press fit in the housing. They are ideal for many of the following applications: transmissions, transfer cases, engines, valve trains, steering and braking systems, axle supports, outboard engines, textile industry, power tools, copiers, fax machines, paper-moving equipment, and appliances.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.