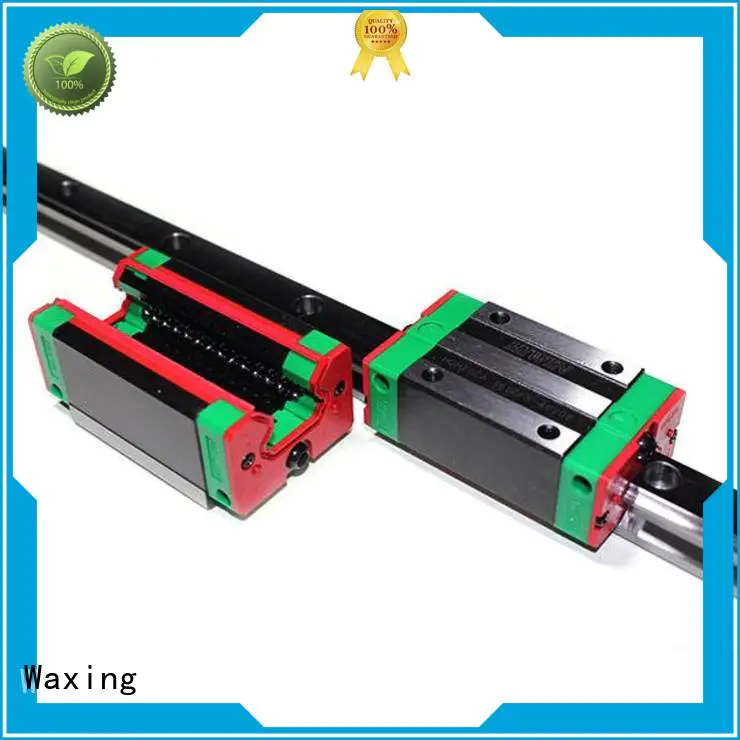

Linear Bearing

Linear bearings generally use a pad, bushing, or roller system to carry a load on a rail that need not be a straight line. The rail can be most any length, although that dimension is limited by the actuator.

The durability of the bearing is determined by the load and required speed. Furthermore, rails can generally be any profile – simple flat surfaces, round polished rods, or complex profiles with polished ground surfaces on which balls or cylindrical rollers can ride. Hard (Rockwell 60) and ground bearing surfaces work best.

Further classifications might be by size. For instance, miniature linear bearings might work well moving a biologic slide sample just a few millimeters beneath a microscope lens while industrial-bearings on injection molding machines carry tooling of several tons.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.