Related Products

Quick Details

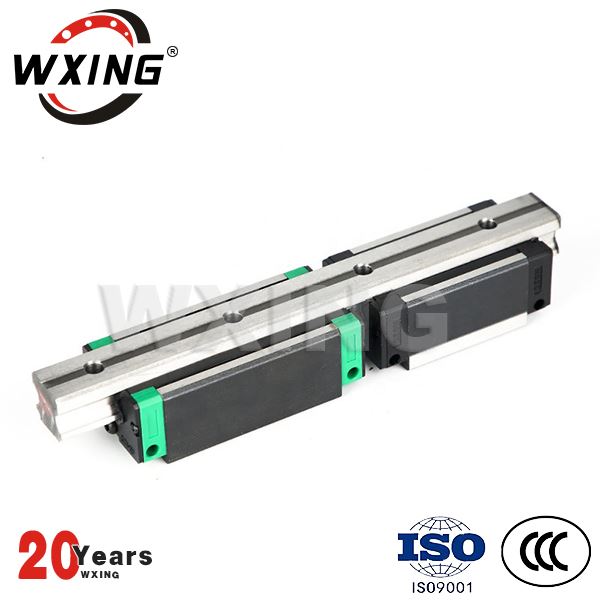

| Type: | Linear guide bearing | Model Number: | HGR20 HGH20CA HGW20CC |

| Brand Name: | WXING or OEM | Product name: | cnc linear guide rail systems ways HGR20 HGH20CA HGW20CC |

| Material: | Chrome Steel Gcr15 | Application: | cnc linear guide rail systems ways |

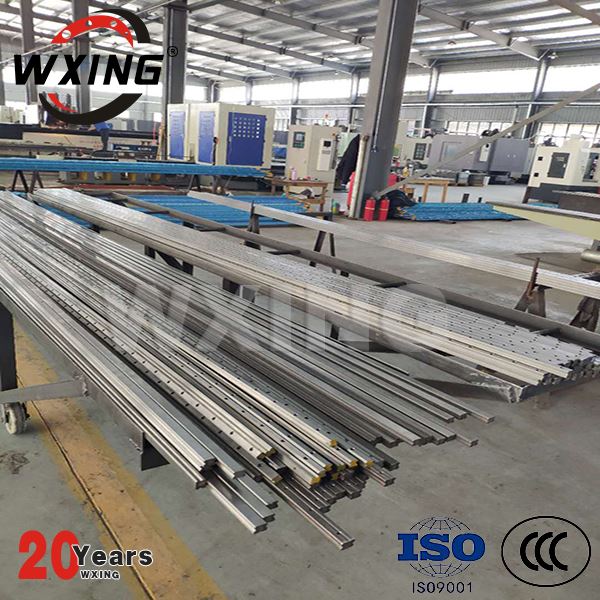

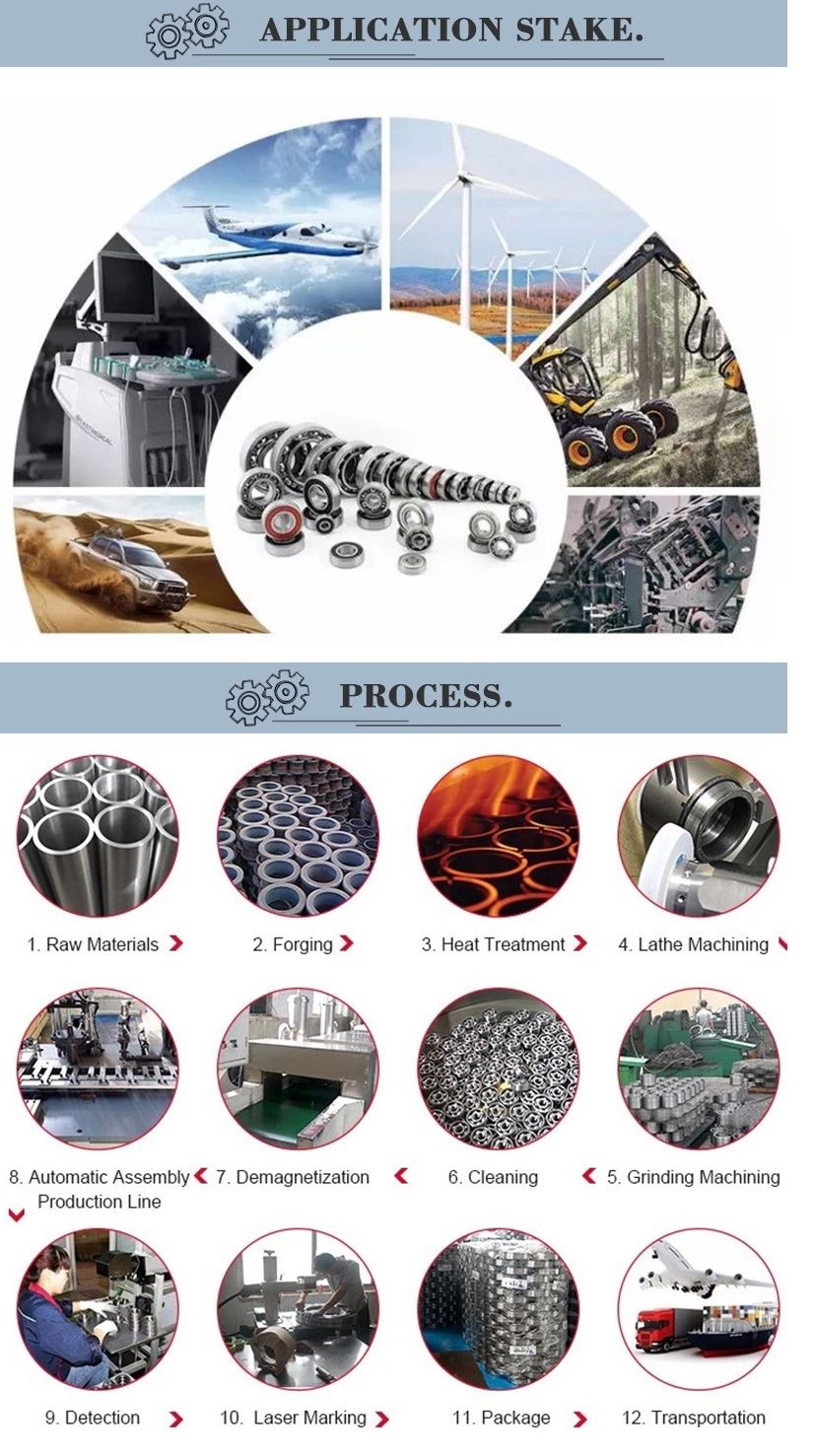

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Printing Shops, Construction works , Energy & Mining, Advertising Company, CNC machinery | Place of Origin: | Shandong, China |

| straightness: | less than 0.03mm | height tolerance: | less than 0.015mm |

| parallelism: | less than 0.01mm | linear guide precision grade: | P |

| Stock: | Rich | Sample: | available |

| Feature: | linear guide rail systems |

Product Description

| Product Name | Factory directly sale cnc linear guide rail systems ways HGR20 HGH20CA HGW20CC |

| Material | Bearing Steel |

| Characteristics | High pressure , large load , good rigidity , smooth operation |

| Type | HGH HGW EGH EGW MGN MGW |

| Application | Automation industry, CNC machine |

| Packing | Plastic bag+wooden box or according to customer's demands |

| Normal color | Black/black+red/black+green |

Products Show

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.