CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

Development background

As a series of environmental problems caused by the greenhouse effect and exhaust emissions are increasingly aggravated, the popularization of more environmentally friendly electric vehicles has become a common expectation of the society. An important issue for the widespread adoption of electric vehicles is the search for space to carry larger batteries in order to improve range.

In recent years, with the miniaturization and lightweight of the electric vehicle drive system and the increasing market demand for the high efficiency of the drive motor, higher speed requirements have been put forward for the ball bearings for the drive motor support. Under high speed rotating condition, due to the influence of heat, the ball bearing will suffer from bad lubrication and lead to bite and stick. In addition, due to the influence of centrifugal force, the cage deformation and damage is an urgent problem to be solved.

Characteristics of high speed ball bearings

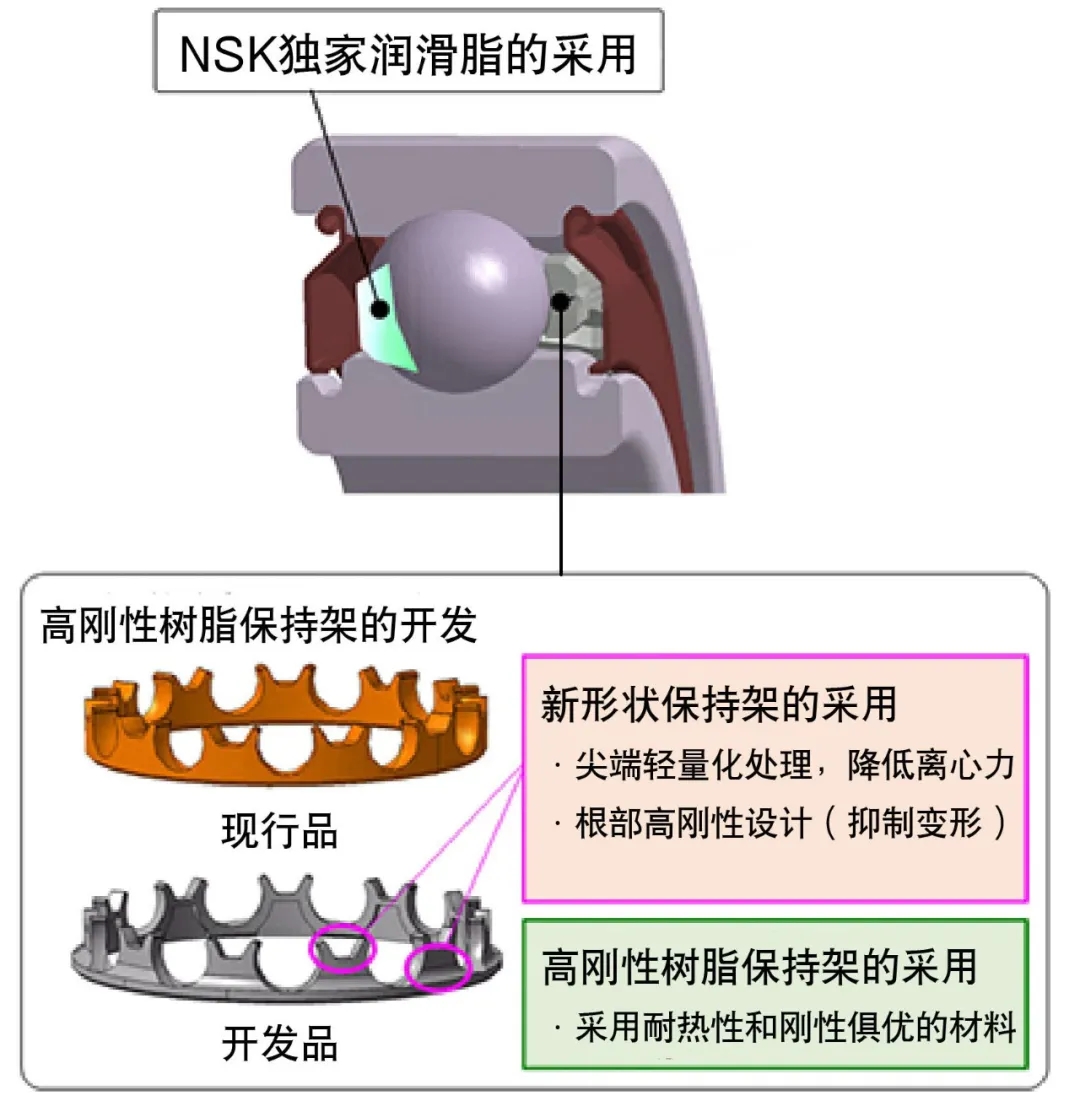

1. NSK developed grease with excellent anti-bite viscosity

Through the use of NSK exclusive development of the grease, can inhibit due to the heat caused by poor lubrication, and compared with the traditional grease can extend the service life.

2. Development of new shape cage

The influence of centrifugal force is reduced by reducing the thickness of the cage's front end and lightweight design. Meanwhile, the deformation of the cage during high-speed rotation can be restrained by improving the rigidity of the cage's bottom. The application of the shape of the cage can greatly reduce the deformation of the cage when rotating at high speed.

3. Development of highly rigid resin materials for retainers

In order to restrain the deformation of the cage when rotating at high speed, a resin material with excellent heat resistance and rigidity was developed successfully. This resin material can greatly reduce the deformation of cage caused by centrifugal force during high speed rotation.

Through the application of the lubricating grease developed exclusively by NSK and the newly developed resin cage, this product can achieve the corresponding working condition of high speed rotation of dmN * 1 = 1.4 million (bearing inner diameter: 35mm; Speed: 30000rpm).

*1dmN: the product of [bearing pitch circle diameter (dm)] and [speed (N)], is the index of bearing speed performance

The effect of development product

This high speed ball bearing is the world's highest limit speed ball bearing *2. The successful development of this product provides the possibility for the large increase of electric vehicle drive motor speed. At the same time, by improving the efficiency of the driving motor, the driving motor can be miniaturized and lightweight, which contributes to reducing the energy consumption of electric cars, extending the range of driving and improving the driving comfort. By the end of 2020, a bearing (dmN value of 1.6 million) that can adapt to higher speed requirements will be released.

*2: social investigation results (grease lubricated bearings)

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.