Related Products

Quick Details:

| Type: | Slewing Bearing |

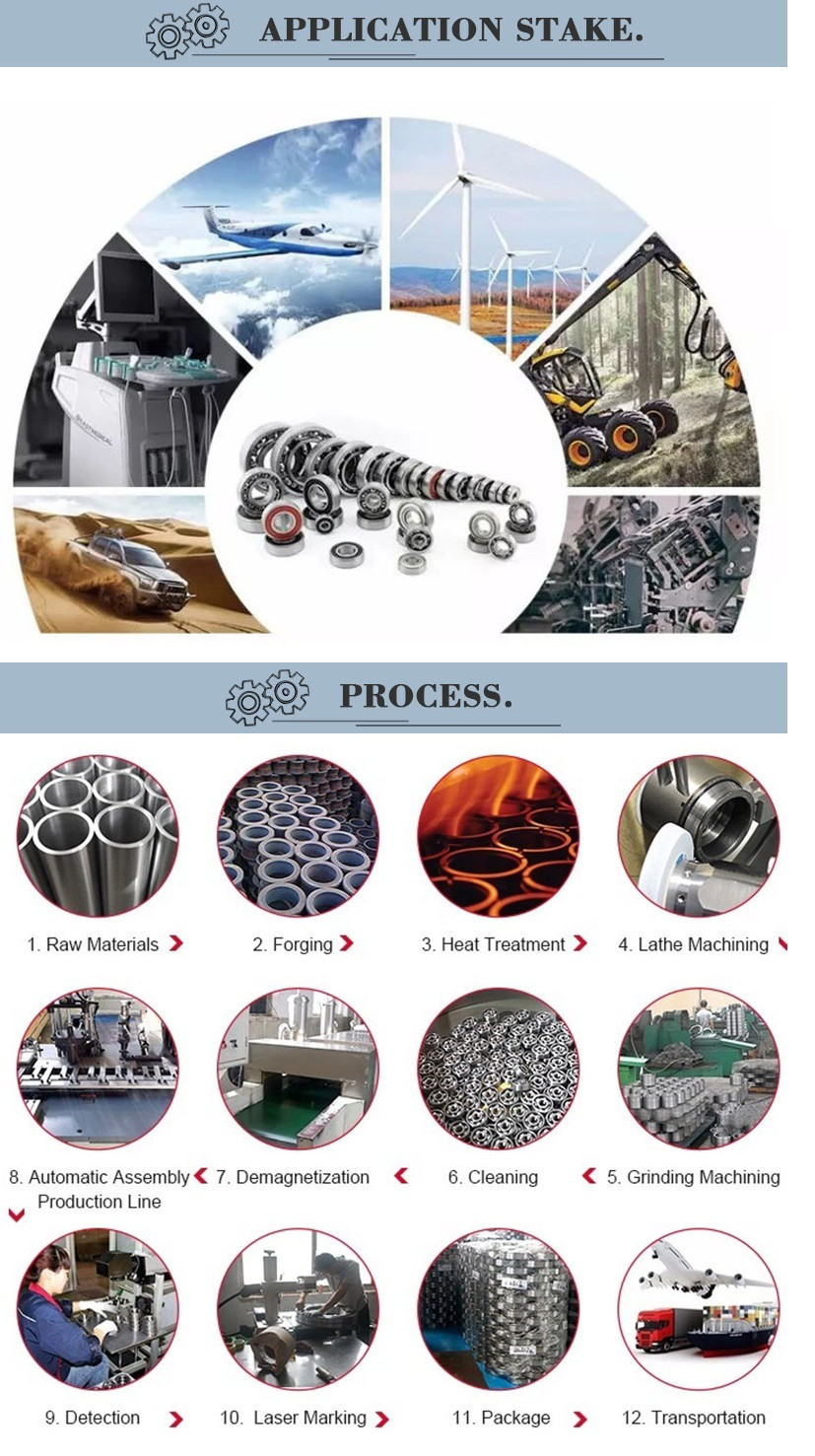

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining |

| Brand Name: | Waxing |

| Model Number: | 435 LONG ARM |

| Feature: | Four Point Contact |

| Seals Type: | rubber seal |

| Place of Origin: | China |

| Gear Options: | External Gear,Internal gear,Nongeared, |

| Material: | 50Mn/42CrMo/S48C/42CrMo4/16Mn |

| Application: | Cranes, Excavators, Tower cranes |

| Hardness: | 229-269H (slewing Bearing) |

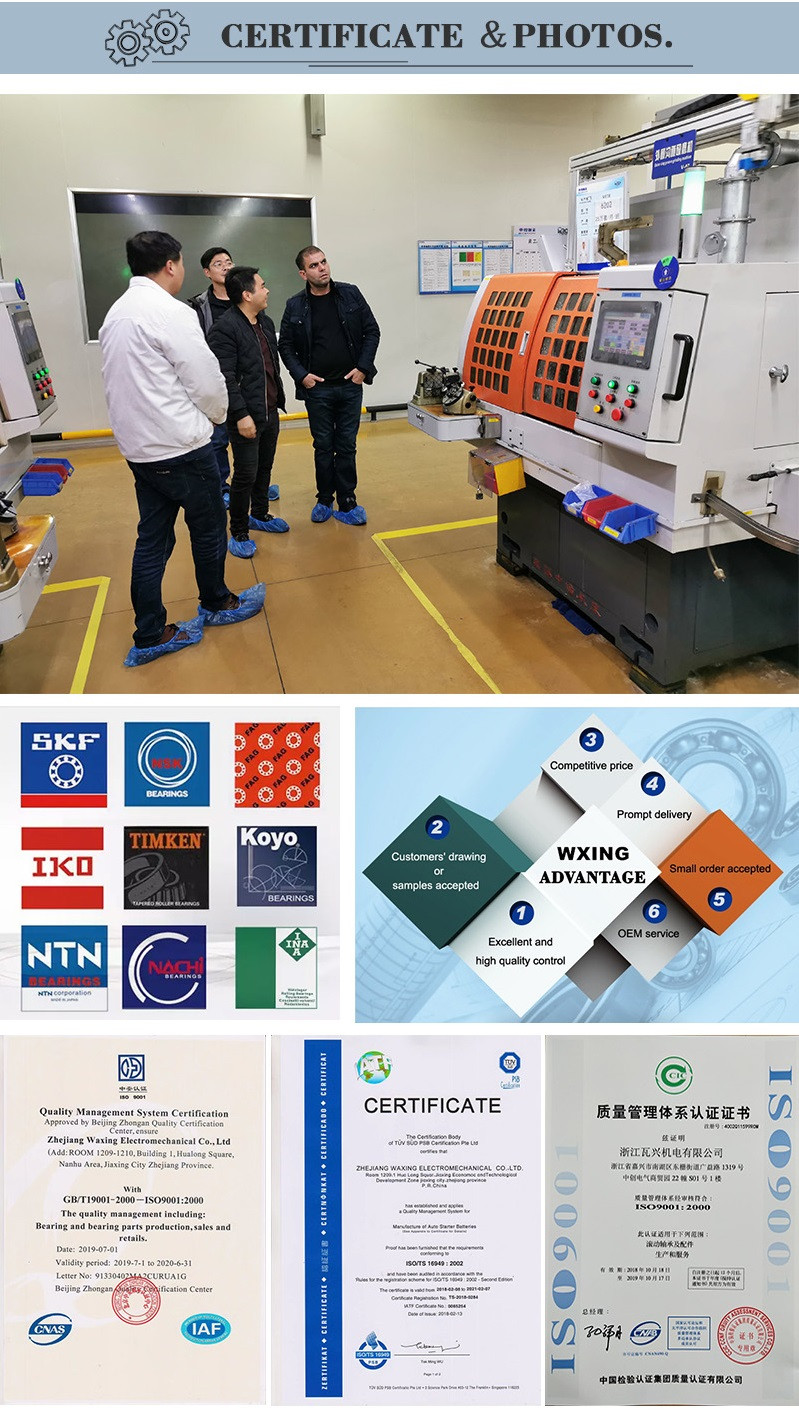

| Certificate: | ISO9001 |

| Services | OEM |

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.