Quick Details:

| Type: | BALL, Self-aligning Ball Bearing | Model Number: | 1322K+H322 |

| Structure: | Self-Aligning | Size: | 100x240x50/77mm |

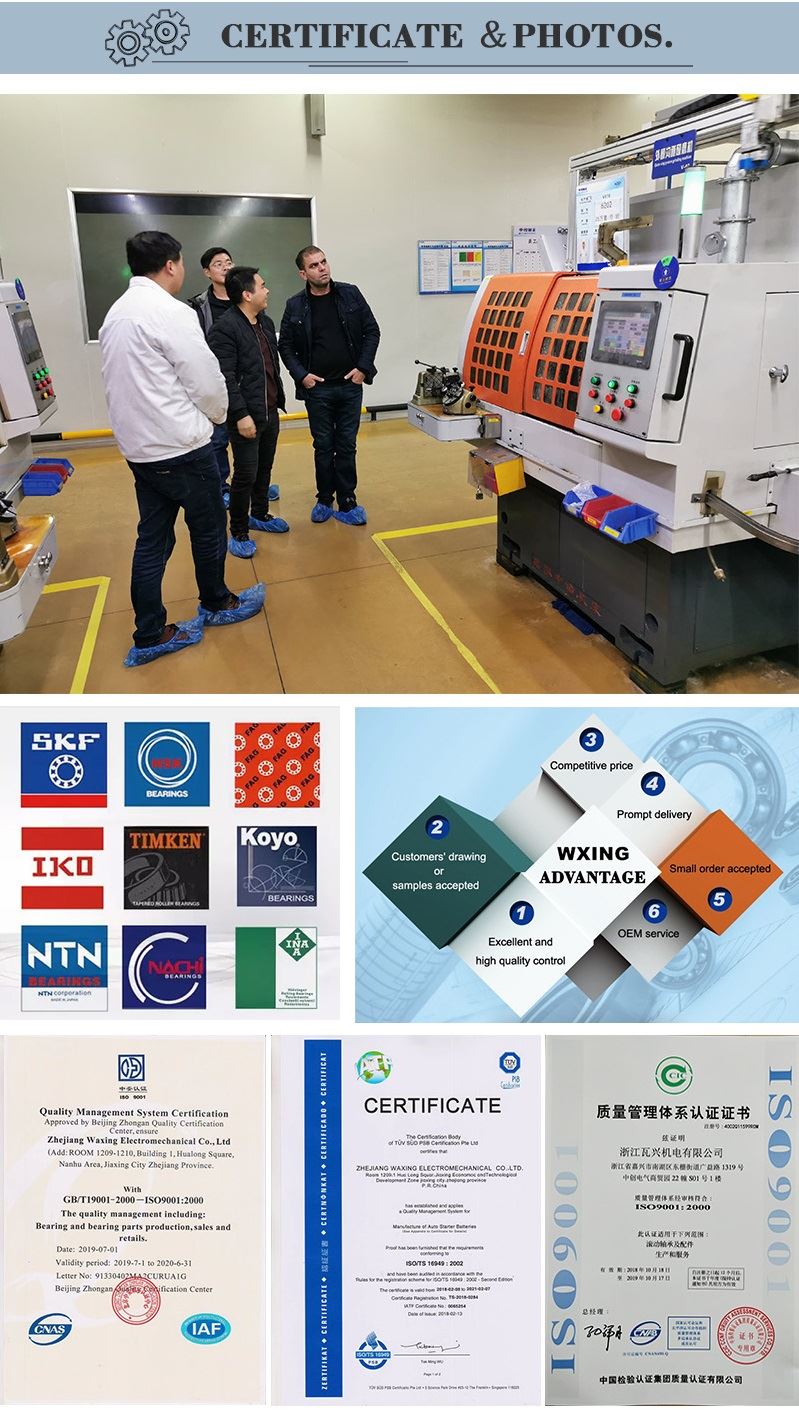

| Brand Name: | WXING or OEM | Product name: | High Precision Taper Roller Bearing for Car |

| Material: | Chrome Steel Gcr15 | Place of Origin: | Shandong, China |

| Seals Type: | Open ZZ 2RS | Number of Row: | Double Row |

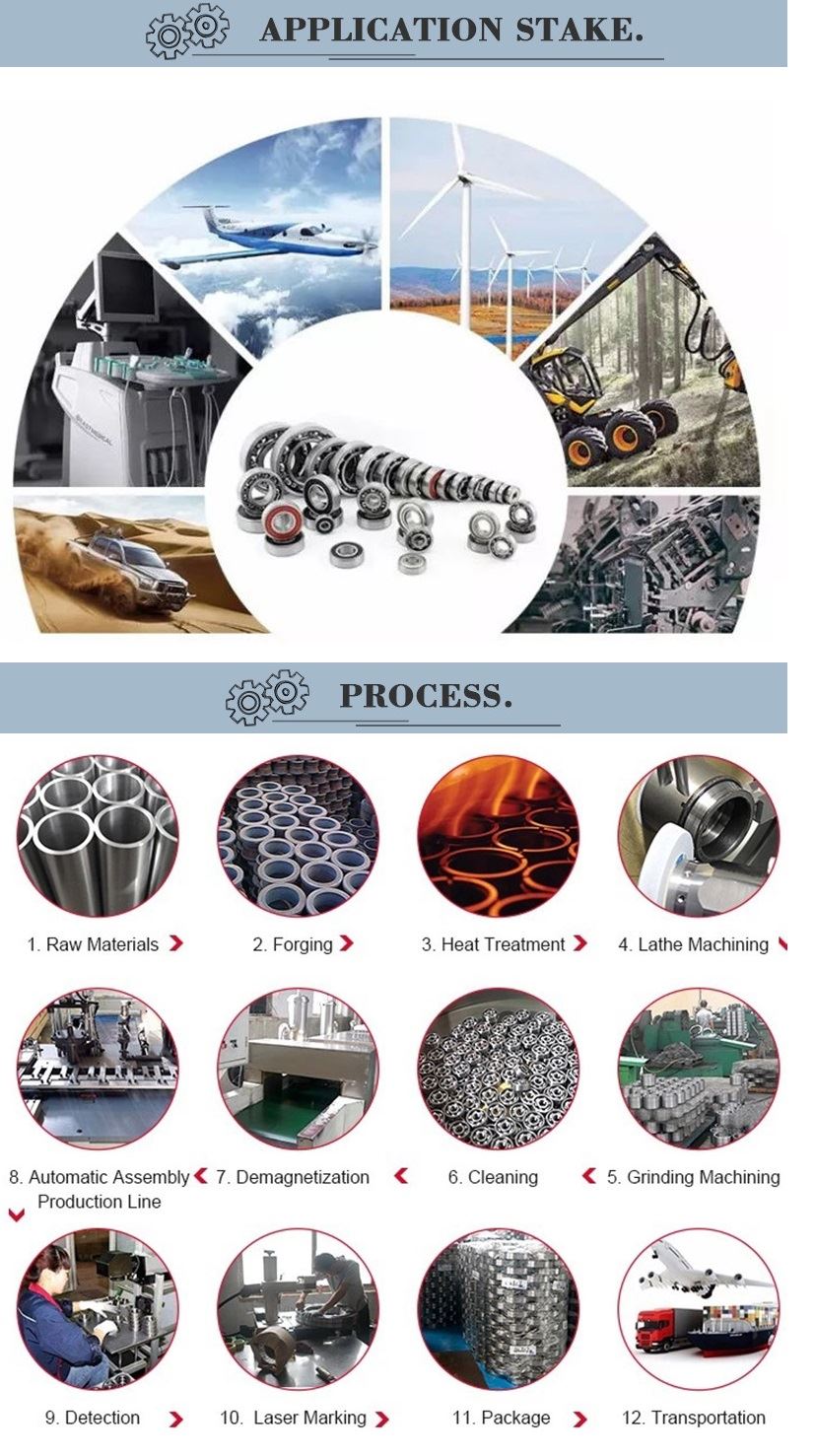

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Printing Shops, Energy & Mining | Precision Rating: | P0 P6 P5 P4 P2 |

| Application: | Machinery parts in Textile/Printing/Package/Mining/Automotive | Feature: | High Performace; High Precision; Low Voice |

| Vibration: | V1 V2 V3 V4 | Noise level: | Z1 Z2 Z3 Z4 |

| Stock: | Rich | Sample: | available |

Supply Ability:

100000 Piece/Pieces per Month Self-aligning Ball Bearing

Packaging & Delivery

Packaging Details

1. Industrial Package: small box+ cartons + wooden case pallets

2. Industrial packing: plastic tube + cartons + wooden case pallets

3. According to customers' requirements

Port:

Qingdao, Shanghai, Ningbo, Shenzhen

Models of Self-aligning Ball Bearing(If you don`t find the model you need, pls contact us.)

Series of Self-aligning Ball Bearing With a Sleeve: 1200k+H200 SERIES; 1300K+H300 SERIES;

2200K+H300 SERIES; 2300K+H2300 SERIES

Detailed Images:

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.