Structure:

Type:

Applicable Industries:

Brand Name:

Model Number:

Precision Rating:

Seals Type:

Number of Row:

Place of Origin:

Material::

Cage::

Application::

Certificate::

Service::

Lubricate::

Feature::

Package::

Size::

Weight::

Selling Units:

Single item

Single package size:

8.5X5.5X3 cm

Single gross weight:

0.450 kg

Package Type:

A: barreled package+outer carton+pallets

B: single box+outer carton+pallets

C: tube package+middle box+outer carton+pallets

D: According to your's requirement

NN3010 K/W33 P4 Super precision cylindrical roller bearing

Cylindrical roller bearings are in linear contact with the raceways. They have a high radial load capacity and are suitable for high speeds.

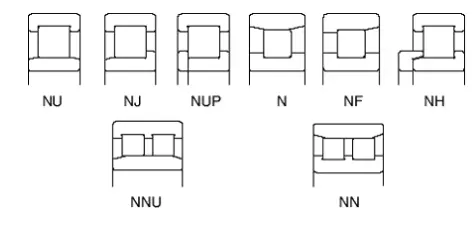

There are different types designated as NU, NJ, NUP, N, NF (for single-row bearings), NNU, and NN (for double-row bearings depending on the design or absence of side ribs).

The outer and inner rings of all types are separable.

Some cylindrical roller bearings have no ribs on either the inner or outer ring, so the rings can move axially relative to each other. These can be used as free-end bearings. Cylindrical roller bearings, in which either the inner or outer rings has two ribs and the other ring has one, are capable of taking some axial load in one direction Double-row cylindrical roller bearings have high radial rigidity and are used primarily for precision machine tools.

Pressed steel or machined brass cages are generally used, but sometimes molded polyamide cages are also used.

Depending on the existence of ribs on their rings, Cylindrical Roller Bearings are classified into the following types:

N type:

The inner ring has two integral flanges and the outer ring is without flanges. Axial displacement of the shaft with respect to the housing can be accommodated in both directions within the bearing itself. The bearings are therefore used as non-locating bearings.

NU type:

The outer ring of bearings of the NU design has two integral flanges and the inner ring is without flanges. Axial displacement of the shaft with respect to the housing can be accommodated in both directions within the bearing itself.

NJ type:

The outer ring has two integral flanges and the inner ring one integral flange. The bearings are therefore suitable for the axial location of a shaft in one direction.

NF type:

The outer ring has one integral flange and the inner ring two integral flanges.

NUP type:

The outer ring has two integral flanges and the inner ring one integral flange and one non-integral flange in the form of a loose flange ring. The bearings can be used as locating bearings, i.e. they can provide axial location for a shaft in both directions.

RN type:

No outer ring and the inner ring two integral flanges.

NN type:

NN type bearing without ribs on outer ring,there is a wall in the midel of between both sides of inner ring. It can make shaft relative bearing between the axial displacement generated in both directions.

Technical data of NN3010

| d | 50mm |

| D | 80mm |

| b | 23mm |

| Precision | P4 |

| Brand | LYZYC or SKF |

| Weight: | 0.45kgs |

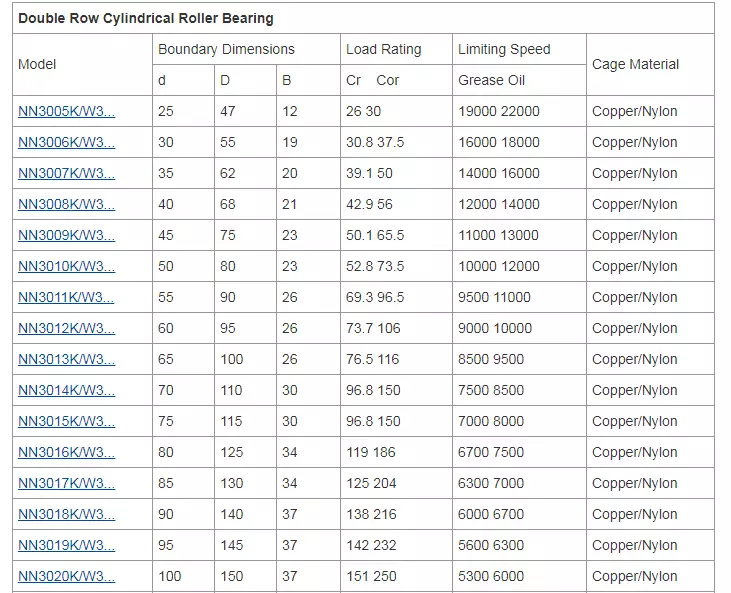

Other double row cylindrical roller bearings we can provide

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.