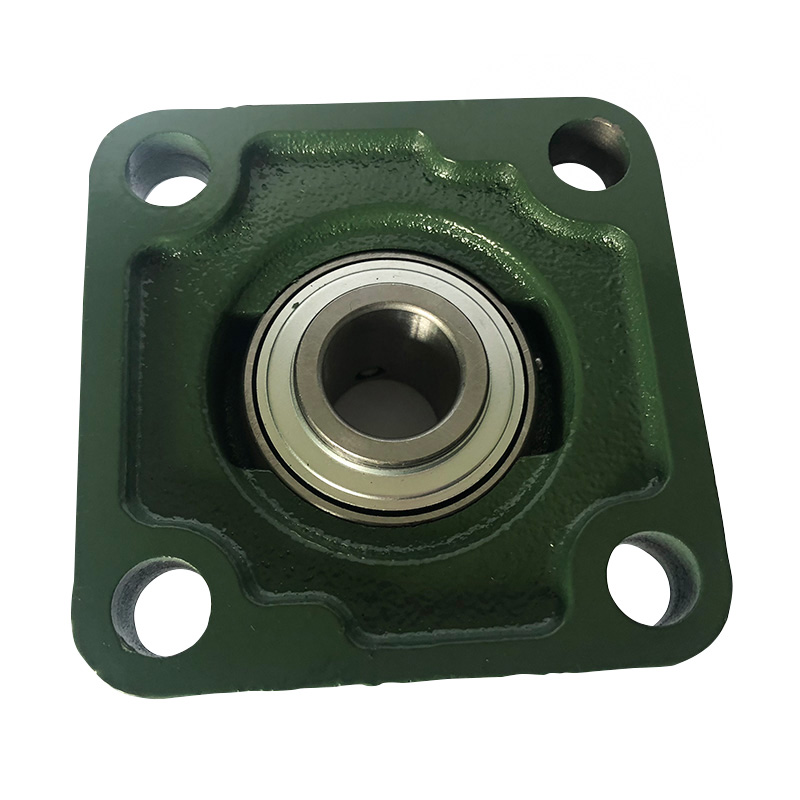

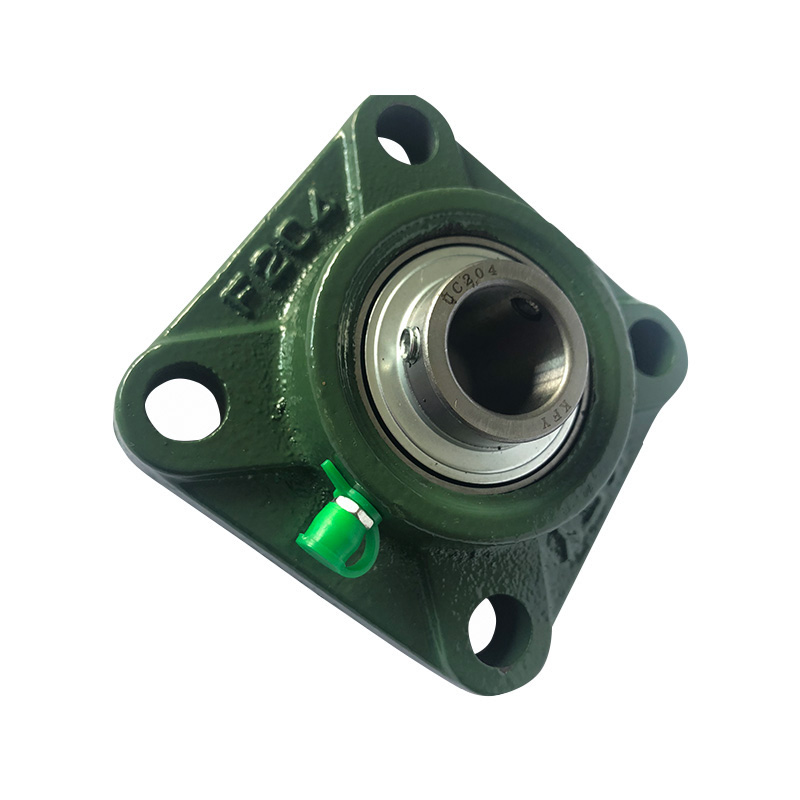

Spherical bearing with seat

Spherical Seat Bearing for Steam Turbine

With our advanced CNC machinery that possesses the capability to produce accurate spherical contours, Jensen Machine builds and supplies high-quality spherical seat bearings that meet with client specifications. Our sophisticated technology provides a +.000/-.001 inch precision tolerance, concentricity with bore within .001 inches, and squareness of faces to bore within .001 inches.

Constructed from 1026 hot finish steel tubing base material and Grade 2, ASTM B23-00, Alloy 2 Babbitt lining, our spherical seat bearings, or, more commonly referred to as journal bearings, are equipped with a split steel shell and a spherical outside diameter with pressure dam in bore. For use by the steam turbine industry, our journal bearings are packaged in special boxes that assure safe transport for on-time delivery to this New York based client.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.