CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

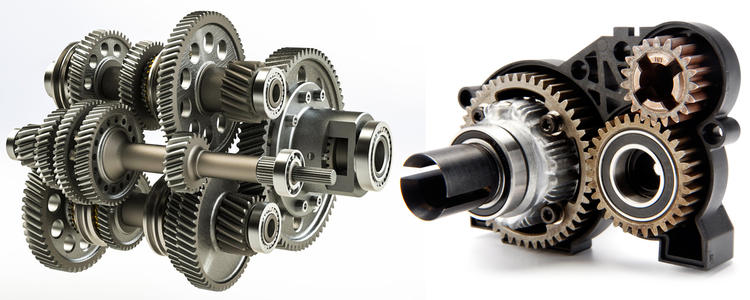

Many gear boxes in the equipment are rolling bearings, the friction between the bearing rolling body and the inner and outer ring is called rolling friction.The fit between bearing and shaft or bearing and end cover is generally interference fit or transition fit.Therefore, the mutual extrusion pressure between the bearing and the shaft, or the bearing and the end cover will be relatively large, resulting in static friction, so that the bearing and the end cover or the bearing and the shaft are in a state of mutual static, at this time, the transfer of mechanical energy is to rely on the rotation between the inner and outer ring and the rolling animal.And if they fit for clearance fit between, can produce a torque to break the relatively static state, the bearing and shaft, bearing and end cover between relative slip occurs, this is called bearing run laps, relative sliding bearing inner ring happens to run in circles, and relative sliding bearing outer ring and bearing housing is to explore the outer ring.

1. Representation of outer ring fault of gearbox bearing

(1) after the removal of the gear box, there are obvious gliding traces on the surface of the outer ring and the inner ring of the bearing seat, and even more, the surface of the shaft or hole will grind out grooves.

(2) the measured hole ratio bearing outer diameter is greater than 0. 015mm.

(3) Generally speaking, the temperature of the bearing part will be higher, and the vibration frequency and amplitude will be larger.

2. Causes of failure of outer ring of gearbox bearing

(1) Fit tolerance.

The matching degree between bearing and shaft, bearing and end cover is very important. The matching tolerance between them has very strict standards and provisions. Once greater than or less than this standard provision, the bearing will have such and such problems, and the phenomenon of bearing running outer ring is very common.In different cases, the requirements for tolerance are not the same.In general, the fit between bearing and shaft, bearing and end cover is interference fit in most cases, a few are excessive fit, these are in line with the rules, once they appear clearance fit, there will be the phenomenon of running outer or inner ring (mainly discuss running outer ring).

(2) machining accuracy and installation accuracy

Processing precision refers to the size, shape, position, roughness and other technical parameters related to the precision of the shaft and the bearing and the bearing base during the production and processing.Installation accuracy refers to the technical standard for the installation of the shaft and the bearing and between the bearing base and the hole.These all have their standard parameter values.Once the tolerance is not accurate, the bearing running will cause wear and even damage to the parts, which has a great negative impact.

(3) Material of shaft and bearing.

Material is also an important factor to consider.The types of bearings are different, and the corresponding bearing materials are different. The strength of bearings and shafts should be large, with high wear resistance and should be reduced as far as possible

The friction coefficient of bearing alloy can better prevent the bearing from running out of the outer ring, and improve the service efficiency and service time of the bearing.

3, the influence of gearbox bearing outer ring failure

The phenomenon of outer ring running in bearings will increase the friction between shaft and bearing, which makes the wear of parts serious and the accuracy decreased.Secondly, due to the generation of friction force, the mechanical energy will be transformed into the thermal energy of friction loss, reducing the transmission efficiency of the whole system.

4, bearing failure prevention measures

Bearing positioning accuracy directly affects the gear clearance, tooth life and even the service life of the box body, which is particularly important for its daily maintenance and fault prevention.When inspecting the daily dimension of the gearbox bearing, we should first pay attention to whether there is noise and abnormal fever during the work of the gearbox. Once the abnormal phenomenon is confirmed, measures should be taken immediately to avoid the expansion of the fault and lead to irreparable damage.Secondly, it is necessary to check whether the gearbox body and its lubrication pipeline leak, whether the lubrication pipeline is loose or even broken.Again, check whether the oil level and oil color of the lubrication station are normal, and immediately find the oil leakage point when the oil level drops.When the oil color is abnormal, the quality of the oil should be checked.Oil sampling should pay attention to the selection of poor operating conditions of the gear box.Then through the inspection of oil results to analyze the working state of the gearbox, to determine whether the performance of lubricating oil can normally meet the needs of equipment operation, if necessary, the bottom of the box (tank) impurities clean, if the bottom of the box is equipped with magnetic components, also need to be cleaned.

(1) repair welding

Repair welding is on the edge of the parts of the surface or coat a layer of good abrasion resistance, corrosion resistance, heat resistance, and other high performance metal layer, in order to protect the internal structure of the original parts, but because of its function and role of different parts, the need to cover the metal layer and the processing craft are also different, thermal stress of repair welding defect is too concentrated, easy to cause deformation of case etc parts.

(2) thermal spraying

Thermal spraying is mainly to atomize the metal layer that needs to be covered by high temperature and then spray it to the parts that need to be sprayed. Thermal spraying requires professional spraying tools and certain skills. The main disadvantage of thermal spraying is that the adhesion is not strong enough and it is easy to fall off.

(3) Brush plating

Brush plating is the process of using electrolysis chemical method to cover the required parts with metal. Its advantage is that it can be repaired in line, but its disadvantage is also very obvious. The metal coating is limited by the amount of wear.Generally can not exceed the thickness of 0. 02mm.

(4) Laser cladding

Laser cladding technology refers to a method in which the coating and the coating surface are melted together by laser technology with different packing methods on the surface of the coated material, and then the coating is covered on the parts.Its advantage is not affected by the matrix metal, cooling speed is fast, its disadvantage is easy to change, may produce cracks.

(5) Solei process repair technology

"Sauvy carbon nano polymer material is made of polymer, metal, nanometer ceramic powder, carbon nanotubes, graphene, and other advanced materials in curing agent, fixed-line promoter compound and into, under the catalysis of various materials complement each other, can better than raw materials", make it has strong adhesive force, good mechanical properties and the advantages of strong corrosion resistance.Solei process repair technology is a new superior technology for the repair of the outer ring of the bearing.Solei material long service life, does not have the stress, does not have the high requirement to the thickness, the repair time is short, greatly improves the product efficiency.When the speed is below 1000 RPM, a variety of disassembly free repair methods can be used to repair the problem, saving a lot of time and labor.In general, the solei process repair technology is much better than the traditional technology, is a highly popular high-tech.

Run laps for the gearbox bearing failure problem, usually, inaccurate fit tolerance, the machining accuracy and installation accuracy of gear box bearing run laps and the influence of the impact of shaft and bearing material to its, can be in based on some remedial measures or increase the preventive measures, so that we can further to run laps bearing fault phenomenon for prevention and control.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.