CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

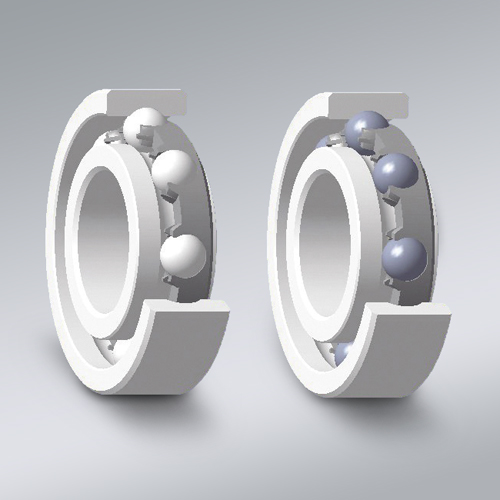

Bearings for non-magnetic requirement are classified into non-magnetic (relative permeability 1.01 or less) bearings and completely non-magnetic (relative permeability 1.001 or less) bearings. Both bearings are harder and more resistant to corrosion than conventional stainless steel or beryllium-copper alloys.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.