CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

1. Selection of spindle rolling bearings.

Spindle and bearing have manufacturing errors, which must affect the rotation accuracy of spindle components.When the spindle assembly is assembled, the rotation precision can be further improved if the error effects of the two offset each other partly.Because the inner ring of the rolling bearing rotates with the spindle, its radial runout (or vibration) has the greatest influence on the rotating accuracy of the bearing.Therefore, only the relative position of the bearing inner ring and the spindle journal is generally adjusted.

(1) Front bearing selection: because the radial runout of the spindle at the front support has the greatest impact on the rotation accuracy of its end, the bearing selection method should be adopted first to reduce the radial runout at the front support.The actual operation process is to measure the inner ring and spindle journal of a batch of rolling bearings respectively before assembly, and type marks at their high points (bearings in some countries have marks at the high points, but in recent years with the improvement of bearing accuracy, the marks will be removed);Then they are grouped according to the actual radial runout amount, and those whose runout amount is similar are taken for assembly, so that the high points of the two are different, that is, the selection of front bearings is completed.

(2) rear bearing selection: after the front bearing selection, the rear bearing selection can further improve the rotation accuracy of the spindle assembly.Because the spindle is to use the same benchmark to fine grinding each journal, so the front and rear journal of the spindle axis beating high point, often in the same direction.Therefore, as long as the rear bearing and the high point of the front bearing are arranged in the same axial plane and the axis is on the same side, better results can often be obtained.If the diameter jump point of the outer ring of the front and rear bearings is installed in the same direction, and the high point of the seat hole is different, the rotation accuracy of the spindle can be further improved.

2. Clearance (clearance) of spindle rolling bearing and its adjustment.

The clearance amount (clearance amount) of spindle rolling bearing has an important influence on the working performance and bearing life of spindle assembly.When the bearing is working under a large clearance, it will cause the deviation of the spindle position (radial or axial) and directly affect the machining accuracy.At this time, the bearing bearing area is also small, the load concentration action to the force direction of one or several rolling body, resulting in greater stress concentration, causing the bearing ripening and wear aggravation and reduce the life.

In addition, the stiffness and vibration resistance of the spindle assembly are greatly weakened.When the bearing is adjusted to zero clearance, the bearing area increases, the rolling body tends to be uniform, and the rotation accuracy of the spindle is improved.When the bearing preload (preload) is adjusted to negative clearance, the rolling body produces elastic deformation, and the contact area with the raceway is increased, so that the bearing area is expanded to 360°, then the stiffness and vibration resistance of the spindle assembly can be significantly improved.Therefore, keeping reasonable clearance of rolling bearings is an important measure to improve the rotation accuracy, stiffness and vibration resistance of spindle components.

The static stiffness of spindle assembly increases with the decrease of bearing clearance.The stiffness change (curve slope) of the bearing near zero clearance is the largest, and then the stiffness increases slowly.However, the influence of bearing clearance on the dynamic characteristics of spindle assembly is more complex.The damping value of the spindle assembly (the ratio between the actual damping value and the critical damping value is that the damping ratio first increases with the decrease of bearing clearance, and the damping value reaches the maximum at zero clearance, and then increases with the decrease of clearance), but the damping value also decreases.

This is because the bearing gradually tends to be "rigid body", so that its structural damping decreases, and more material internal friction damping characteristics.The static stiffness and damping characteristics jointly affect the overall dynamic response of the spindle assembly. There is an optimal clearance position, when the common amplitude of the front end of the spindle is the minimum, the static stiffness and resonance frequency are both high, and the roundness error and roughness of the machinated surface are also small.When the clearance amount is too small, the improvement of stiffness is not significant, but the wear and heat of the bearing are greatly increased, thus reducing the life of the bearing and worsening the service conditions.Therefore, it can be seen that the selection of the optimal clearance amount of bearings should not only consider the static stiffness, but also consider the damping value, so as to obtain the minimum common amplitude value of the shaft end, higher stiffness, resonance frequency and machining accuracy.According to experience, the bearing clearance of general medium and large machine tool spindles should be adjusted by -0.005 ~ -0.015mm.

3. Detect and adjust the installation of bearing inner and outer rings.

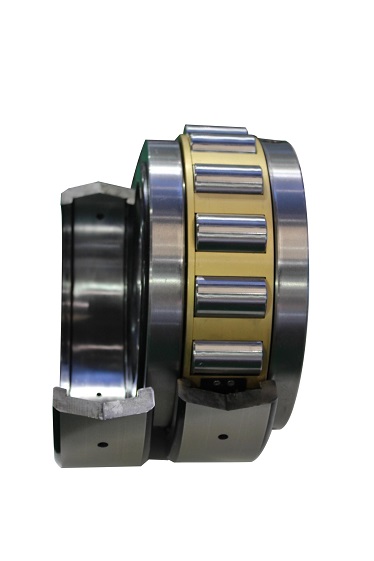

The diameter and width ratio of double-row cylindrical roller bearings is generally between 4 and 7. Because the diameter and width of double-row cylindrical roller bearings are relatively large, the guiding performance of double-row cylindrical roller bearings is poor when they are installed in the headstock hole and the spindle.Moreover, the size and mass of large machine tool parts are large, which brings some difficulty to the assembly work, and easy to cause uneven force when installing bearings.The above reasons lead to the deviation of the inner and outer ring installation position of the spindle bearing, the poor contact between the bearing rolling body and the inner and outer ring of the bearing, resulting in the reduction of the spindle stiffness and rotary accuracy.The method of checking the installation of the inner and outer rings of the spindle bearing is as follows: in the process of pretightening the inner ring of the bearing, keep rotating the spindle and observe the rotation of the bearing rolling body at the same time.

If the spindle rotates easily, and the rolling body of the bearing rotates with the spindle, the inner and outer rings of the bearing should be installed correctly;If the spindle has a certain amount of preload, there is a block when rotating, and the bearing individual rolling body does not rotate with the spindle, or the rolling body is loose when moving by hand, it should be caused by the installation deviation of the inner or outer ring of the bearing.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.