Deep groove ball bearings (DGBB) are the most common types of bearings which are durable and easy to maintain. Having a simple structure consisting of an outer ring, an inner ring, a ball, and a cage in various sizes, these are available in single and double-row designs as well as in open and sealed variants. Compared with the other kinds of bearings, DGBB have a very low frictional coefficient and high speed limit which makes them unable to endure high impact and heavy loads.

Product Name

Deep Groove Ball bearing 6202

Materia

Bearing Steel Gcr15/Chrome Steel

Number of Row

Single Row

Size

35x15x11mm

FOB Port

QINGDAO,CHINA

Payment

100% T/T payment before shipping

Delivery Details

5-30 days

Brand

WXING or OEM

Features

Deep groove ball bearings are the simplest yet the most popular bearing: Suitable for very high rotating speeds Well suited for medium high radial and axial loads in one or both directions Various seals and grease variants available for different operating conditions Numerous clearance and tolerance classes available for different operating conditions Standard: DIN 625 Series: 600, 6000, 6200, 6300, 6400, 1600; Thin-ring: 61800, 61900

Application:

Mainly used in metallurgy,mining,petroleum,chemical industry,construction machinery and other areas

Application examples: electrical motors,general machinery,industrial gearboxes,pumps agricultural machinery etc.

Workshop

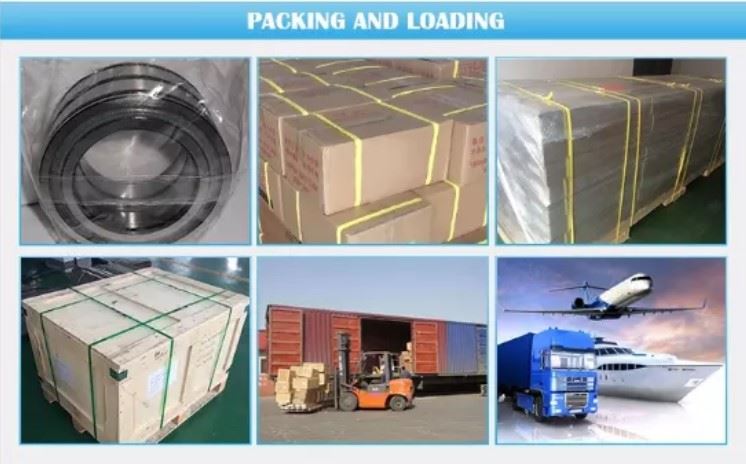

Packing and Loading

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.