Structure:

Type:

Applicable Industries:

Model Number:

Precision Rating:

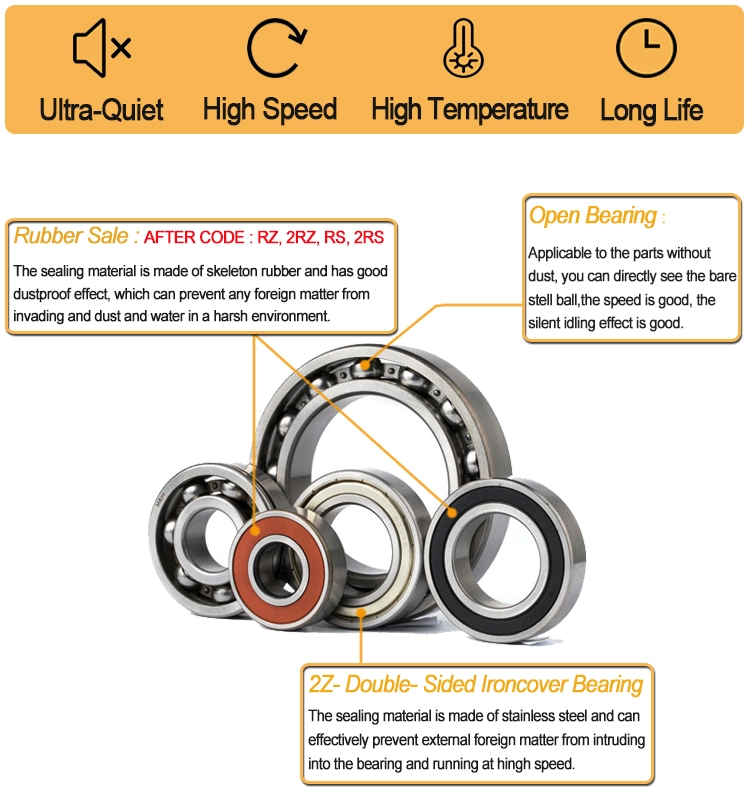

Seals Type:

Number of Row:

Place of Origin:

Product name:

Brand:

Cage:

Package:

Feature:

Service:

Seal:

Noise level:

Lubrication:

Material:

Supply Ability:

300000 Piece/Pieces per Week

Packaging Details

1. Industrial packaging: plastic bag + kraft paper + carton or wooden box; Plastic wrap + carton + tray

2. Commercial packaging :1pc/ plastic bag + color box + carton + tray

3. Packing according to customs requirements

Port

Qing Ddao

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.