Thrust Ball Bearing

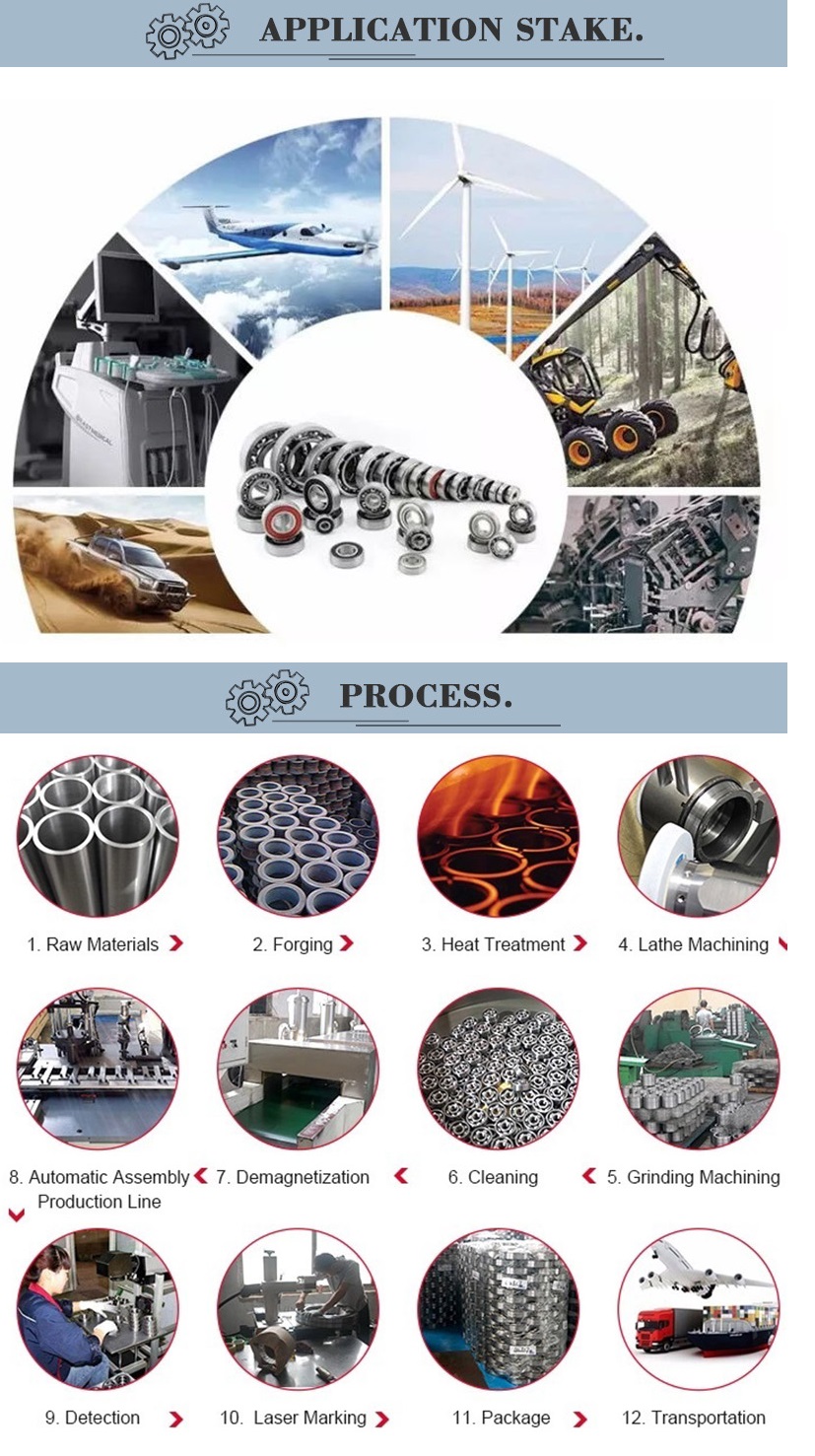

Thrust bearings are designed to accommodate axial load in one or both directions. The single acting carries the load in one direction while the double acting can carry load in both directions. There are several design types and configurations to suit a variety of load capacities and applications. The Ball Thrust series is available in ABMA Inch series, ISO Metric series, and Angular Contact series. The single acting Inch and Metric series are capable of handling relatively light loads in one direction while the Angular Contact series can handle a combination of radial and thrust loads in one or both directions. The Cylindrical Roller Thrust series is produced in Inch, Metric, Self-Aligning, Crane Hook, and Specialty series, Single and Double Acting. The use of the cylindrical roller design allows for greater thrust load capacities than the same sized ball thrust bearing. This greater capacity makes them suitable for a wide range of applications and industries. Our Tapered Roller Thrust Bearings with high load capacities are suitable for many applications where heavy thrust loads are encountered in the application. These are widely used in heavy applications such as coal pulverizing, rock crushing, plastic extrusion, and in rolling mill stands. Because of the heavy loads and severe duty, many of these are produced with case hardened components for more durability. Please consult American for specific design characteristics for each type or let us help with application assistance today.

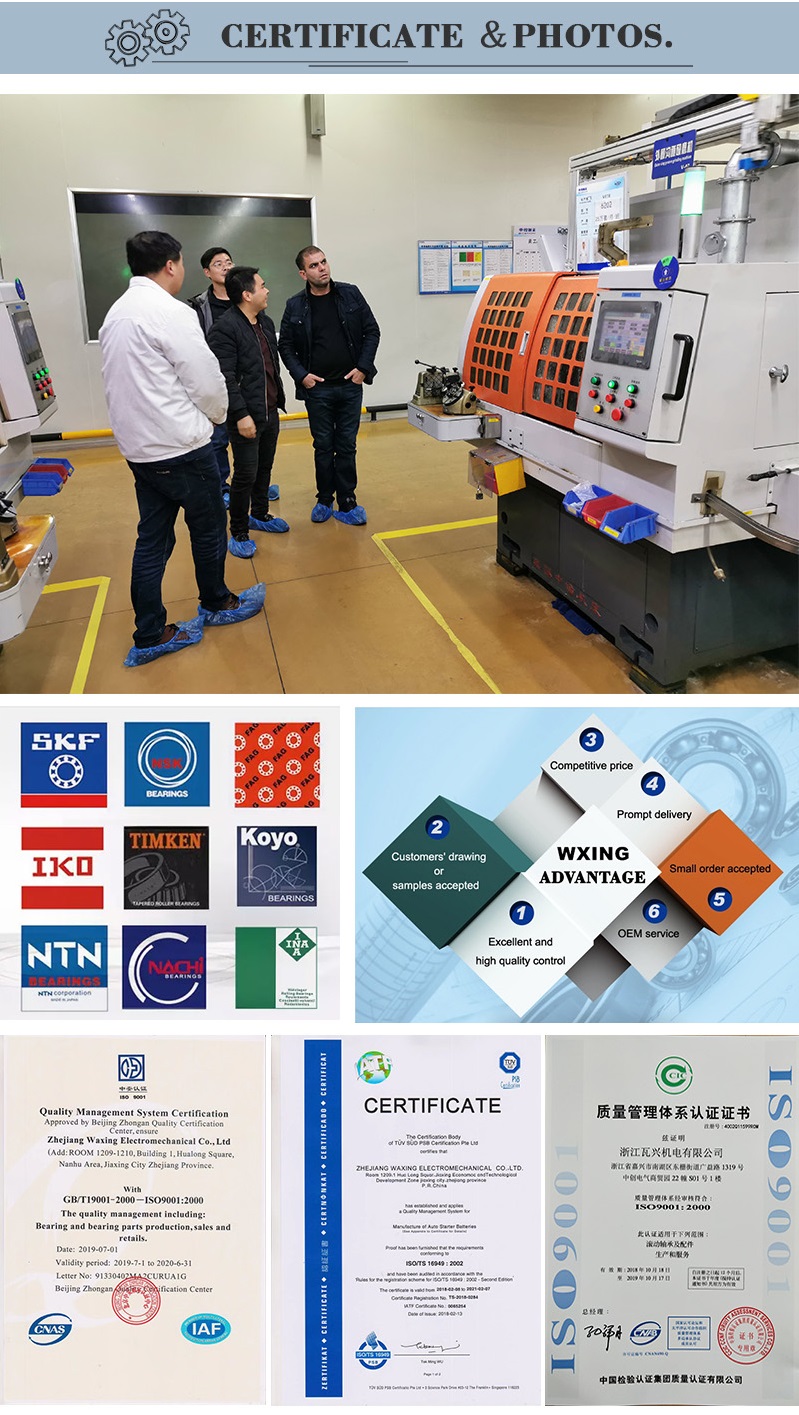

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.