Quick Details:

| Type: | Roller | Brand Name: | WXING |

| Structure: | Taper | Product name: | Mini washing machine parts taper roller bearing |

| Applicable Industries: | Building Material Shops, Manufacturing Plant | Cage: | Steel Cage |

| Size: | 75x130x41mm | Number of Row: | Single Row |

| Seals Type: | Open | Material: | Chrome Steel/GCr15 |

| Place of Origin: | Shandong, China | Clearance: | C2 C0 C3 C4 C5 |

| Feature: | Long Life; Low Noise | Stock: | Rich |

| Model: | 33215 | Precision Rating: | PO, P6, P5, P4, P2 |

| Sample: | Available |

Product Description:

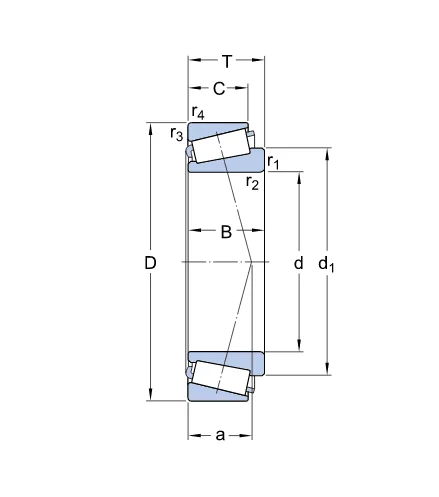

Tapered roller bearings are separable bearings, bearing inner and outer rings have conical raceway. According to the number of rollers in bearings, it is divided into single row, double row and four row tapered roller bearings. Tapered roller bearings are usually separated assembly, Separate installation by conical outer ring and conical inner ring with rollers and cage components. its widely used in automobile, rolling mills, mines, metallurgy, plastics machinery and other industries.

| China factory single row mini washing machine parts 33215 taper roller bearing | ||

| Model | 33215 |

| Size | 75*130*41mm | |

| Material | Gcr15 | |

| Cage | Steel | |

| Seal Type | Open | |

| Quality | ISO9001 2015 Standard | |

| Port | Qingdao, Shanghai, Ningbo, Tianjin, Guangzhou, Shenzhen, Hongkong | |

| Package | Standard exported package or according to our customers' requirement | |

| Delivery Time | within 3 days after confirm, it will be 3~7 days if the goods are not in stock , the specific time need refer to the quantit |

| Related Bearing Models | |||||||

| Bearig Number | Principal dimensions(mm) | Weight(KG) | |||||

| d | D | B | C | r1min | rsmin | ||

| 32014X | 70 | 110 | 25 | 19 | 1.5 | 1.5 | 0.869 |

| 33014 | 70 | 110 | 31 | 25.5 | 1.5 | 1.5 | 1.11 |

| 30214 | 70 | 125 | 24 | 21 | 2.0 | 1.5 | 1.3 |

| 32214 | 70 | 125 | 31 | 27 | 2.0 | 1.5 | 1.66 |

| 33214 | 70 | 125 | 41 | 32 | 2.0 | 1.5 | 2.15 |

| 30314 | 70 | 150 | 35 | 30 | 3.0 | 2.5 | 3.03 |

| 32314 | 70 | 150 | 51 | 42 | 3.0 | 2.5 | 4.35 |

| 32015X | 75 | 115 | 25 | 19 | 1.5 | 1.5 | 0.925 |

| 33015 | 75 | 115 | 31 | 25.5 | 1.5 | 1.5 | 1.18 |

| 30215 | 75 | 130 | 25 | 22 | 2.0 | 1.5 | 1.43 |

| 32215 | 75 | 130 | 31 | 27 | 2.0 | 1.5 | 1.72 |

| 33215 | 75 | 130 | 41 | 31 | 2.0 | 1.5 | 2.25 |

| 30315 | 75 | 160 | 37 | 31 | 3.0 | 2.5 | 3.63 |

| 32315 | 75 | 160 | 55 | 45 | 3.0 | 2.5 | 5.31 |

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.