Structure:

Taper

Type:

Roller

Model Number:

32218

Precision Rating:

P0 P6 P5 P4

Seals Type:

NONE

Number of Row:

Single Row

Place of Origin:

Qingdao, China

Vibration level:

V1 V2 V3

Noise level:

Z1 Z2 Z3

Material:

Bearing Steel Gcr15

Service:

OEM

Package:

Tube or Single Box

Brand:

WXING or OEM

Application:

Machinery

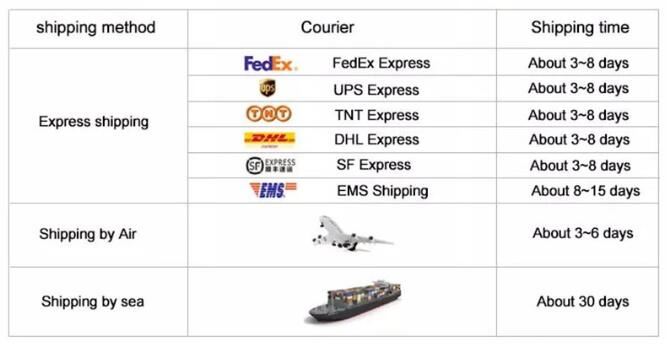

Packaging & Delivery

Packaging Details

1.Tube/Roll+Carton+Pallet

2.Inner plastic paper +Single box+Carton+Pallet

3.According to customers' requirement

Port

Qingdao, China

shipping

PRODUCTION PROCESS

WORKSHOP

TESTING INSTITUTIONS

MORE PRODUCTS

Application

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.