Tapered roller bearing

Tapered Roller Bearing Uses and Advantages

A tapered roller bearing is a unit that consists of both tapered raceways (inner and outer rings), and tapered rollers. The construction is intended for combination loads, such as dual acting axial and radial loads. The bearing axis is where the projected lines of the raceway combine at a common location to improve rolling, while reducing friction. The load capacity can be increased or decreased depending on the contact angle being increased or decreased. The higher the degree of angle, the greater the contact angle. They are commonly used in pairs for better radial load handling, and in some heavy duty applications, can be found in two or four rows combined in a single unit.

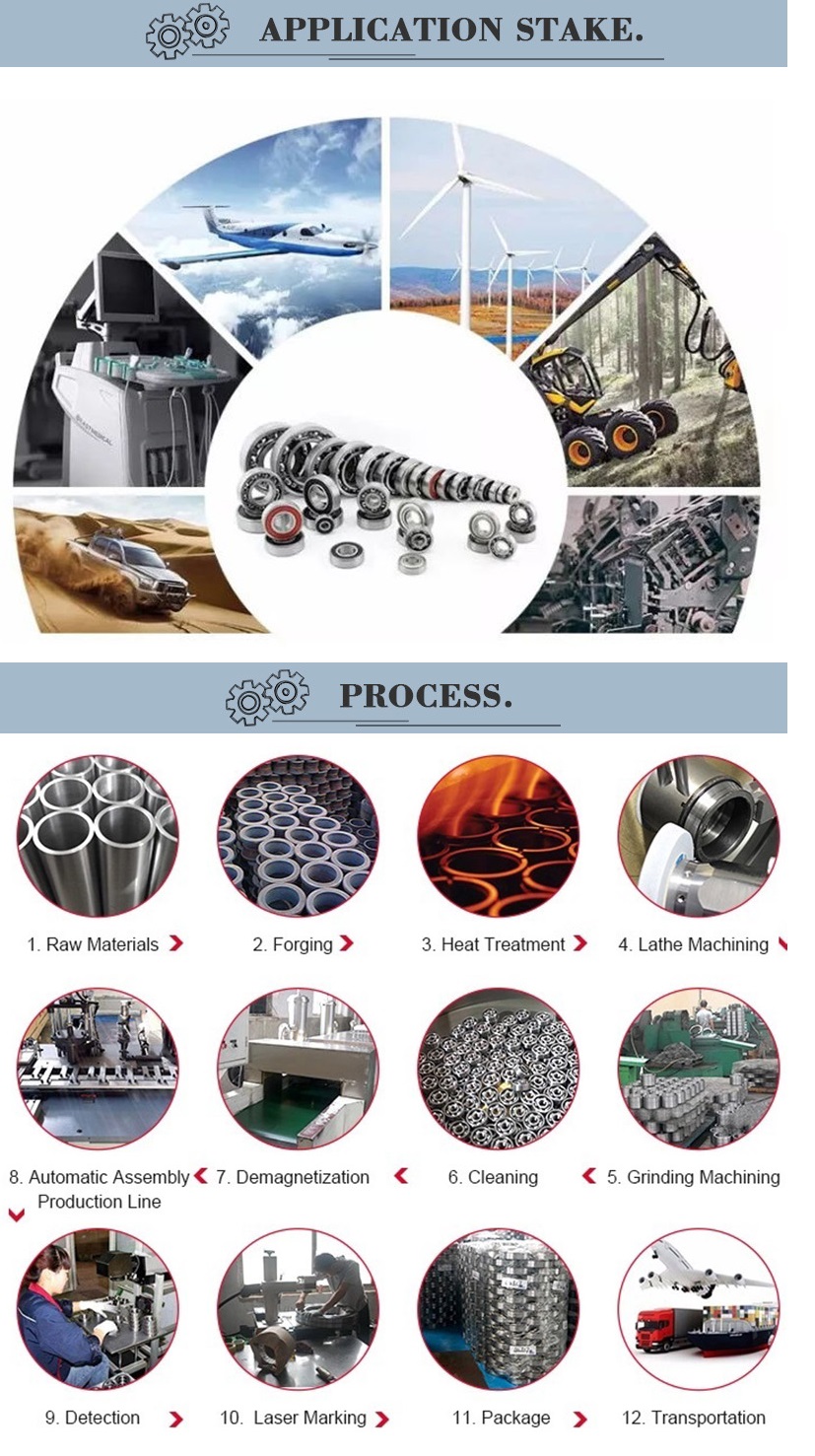

Tapered Roller Bearing Uses

These types of bearings can be found in several everyday applications, most notably in car wheels. While the original design was actually constructed for wagon wheels to improve their performance for farming purposes, they have since been adapted for use across a wide spectrum of the automobile industry. Usually used in pairs in order to support an equal amount of axial force in either direction, they have come a long ways from the days of the wagon wheel. And yet the concept has survived and thrived 120 years later. They can also be found in agriculture equipment, gear boxes and axles, engines and reducers, propellers, railroad axles, and mining and construction.

The Advantages

The tapered roller bearing was designed to reduce friction and in turn reduce the heat generated which caused previous bearing designs to fail. The tapered shape allows the transfer of a load evenly while rolling. This dramatically reduced wear, in turn increasing durability, and is now nearly the world wide application for transmission shafts and rotating axles. Due to the high durability of these bearings, these shafts can usually run maintenance free for hundreds of thousands of miles. They also handle many heavy duty operations because of their reliability.

If you need quality and reliability shipped the same day you order, look no further than The Big Bearing Store to find what you need, in stock. Our BIG selection gives you both options and assurance that you'll find what you are looking for.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.