Manufacturing Plant

Place of Origin:

Shandong, China

Brand Name:

WXING

Model Number:

TCB201

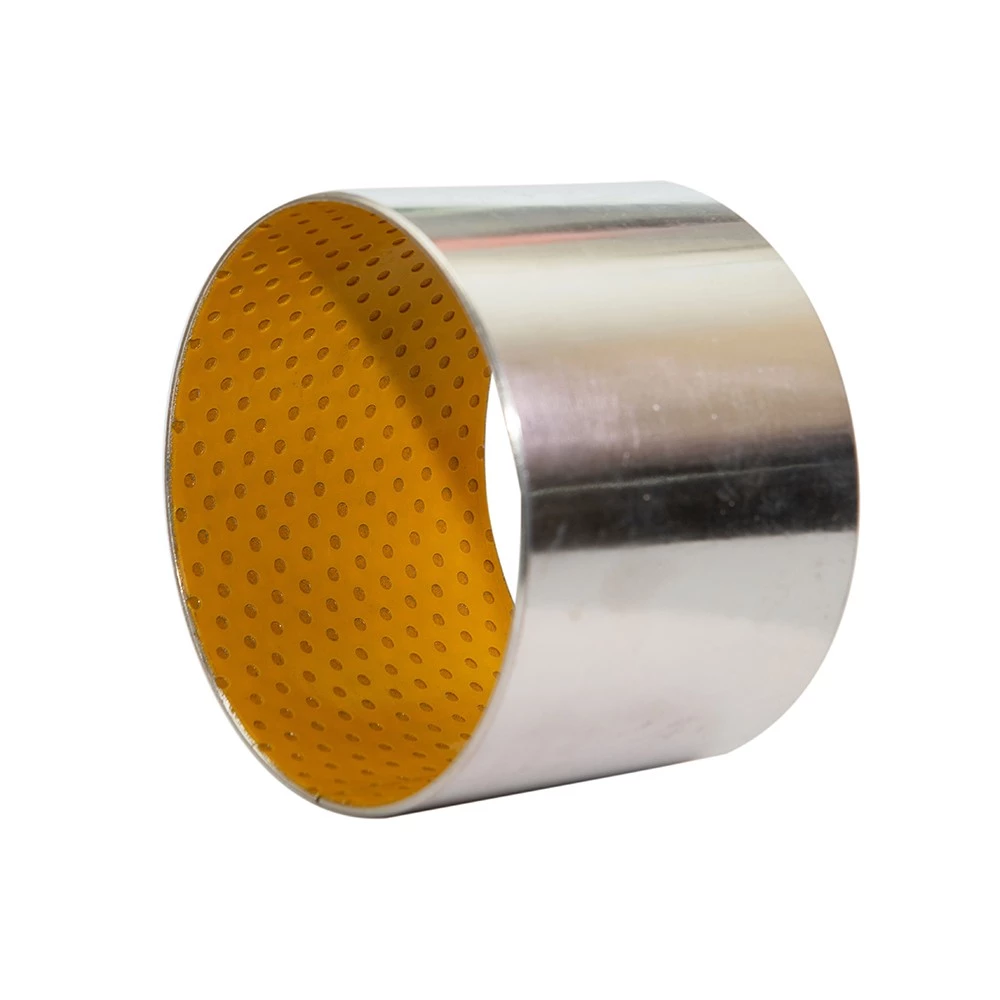

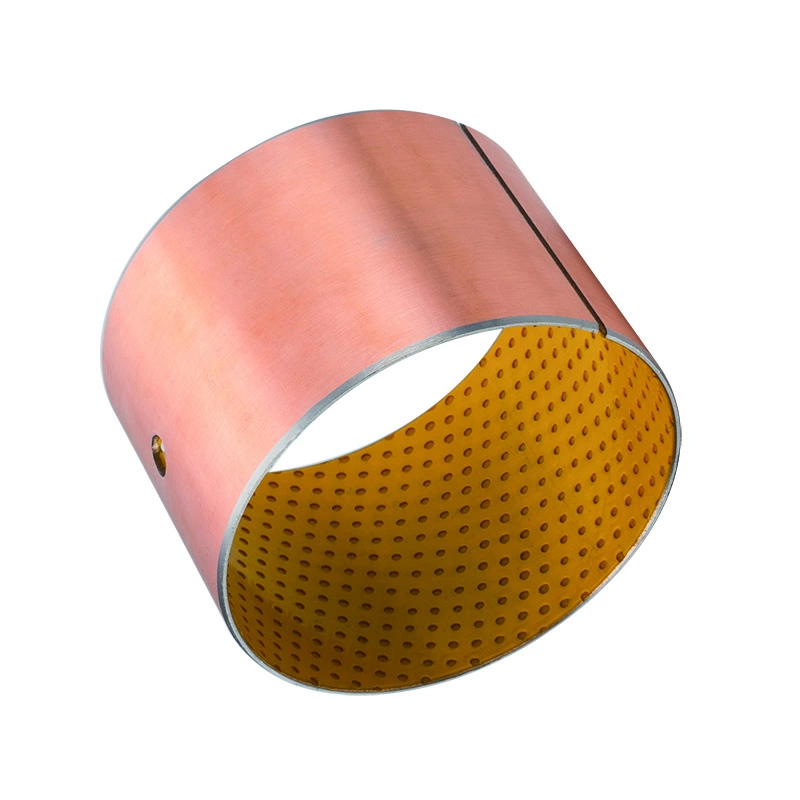

Type:

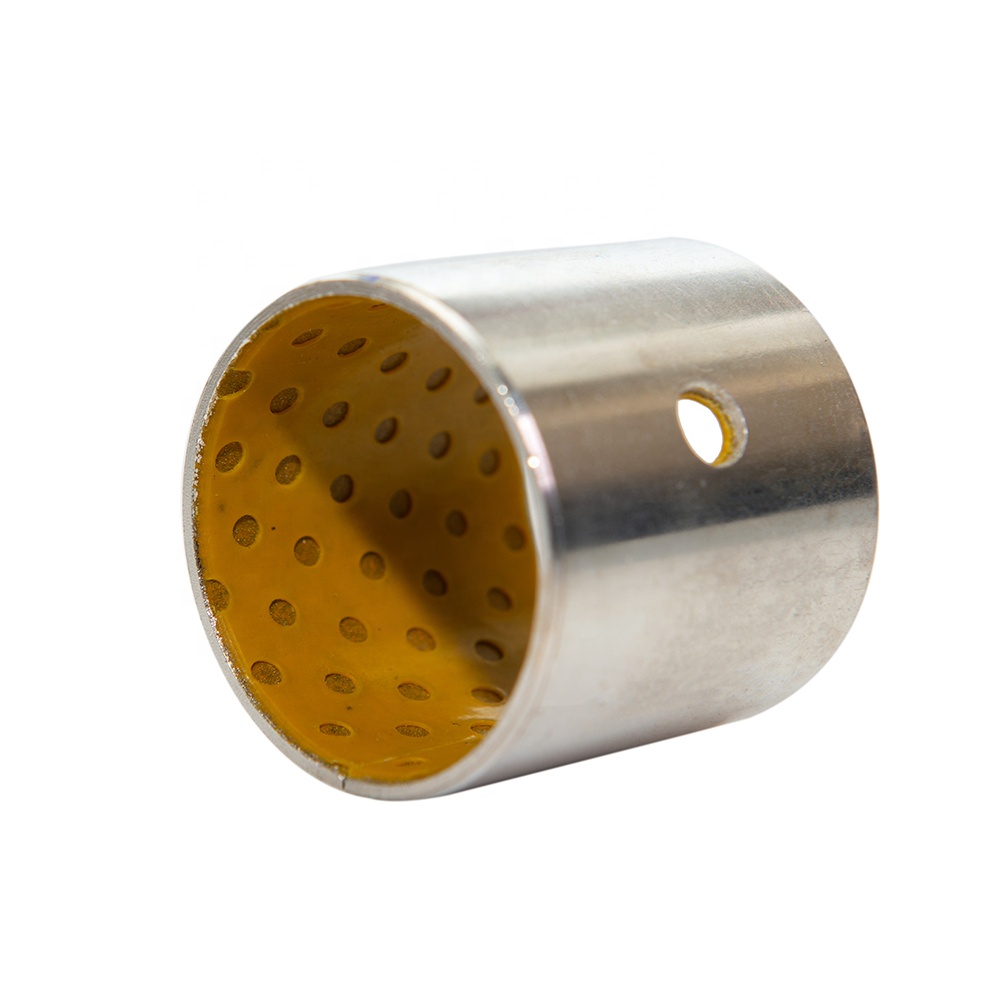

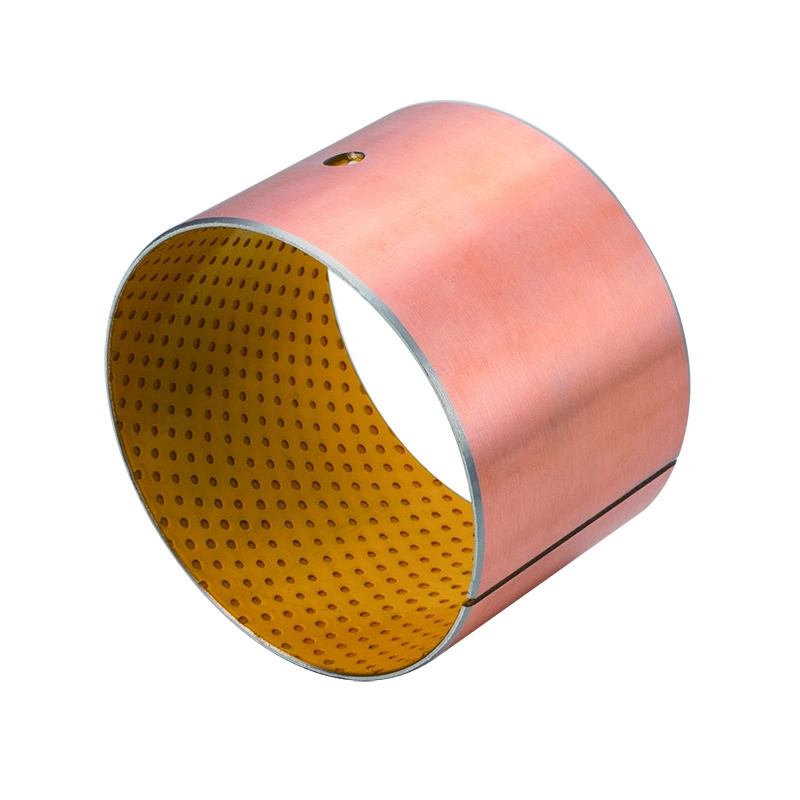

Sleeve Bushing

Material:

Steel base+ Bronze powder+ POM

Product name:

DX Oilless POM Composite Sliding Self Lubricating Bearing Bushing

Size:

customizable

Processing methods:

Cold-extrusion

Surface treatment:

Tin plating /Copper plating

Operating temperature:

-40~120

DETAILS:

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.