Quick Details

Structure:

Cylindrical

Type:

Roller

Brand Name:

WXING or OEM

Model Number:

NJ320

Precision Rating:

P0, P6, P5, P4, P2

Seals Type:

open

Number of Row:

Single Row

Place of Origin:

Qingdao,China

Product name:

NJ320 NJ321 NJ322 EM Cylindrical Roller Bearing

Size:

100*215*47mm

Precision:

P5

Service:

OEM Customized Services

Application:

Machinery

Bearing Material:

100% Chrome Steel/GCr15

Cage:

Steel Cage

Sample:

Avaliable

Packaging & Delivery

Packaging Details

NJ320 Cylindrical Roller Bearing

1. Tube+carton+pallet

2. paper box+carton+pallet

Port

Qingdao, China

Production

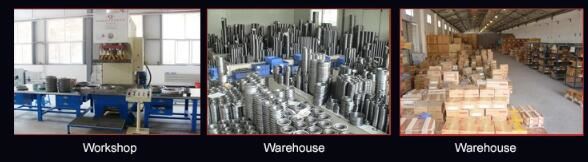

Workshop & Warehouse

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.