A pillow block usually refers to a housing with an included anti-friction bearing. A pillow block refers to any mounted bearing wherein the mounted shaft is in a parallel plane to the mounting surface, and perpendicular to the center line of the mounting holes, as contrasted with various types of flange blocks or flange units. A pillow block may contain a bearing with one of several types of rolling elements, including ball, cylindrical roller, spherical roller, tapered roller, or metallic or synthetic bushing. The type of rolling element defines the type of pillow block. These differ from "plummer blocks" which are bearing housings supplied without any bearings and are usually meant for higher load ratings and a separately installed bearing.

The fundamental application of both types is the same, which is to mount a bearing safely enabling its outer ring to be stationary while allowing rotation of the inner ring. The housing is bolted to a foundation through the holes in the base. Bearing housings may be either split type or solid type. Split type housings are usually two-piece housings where the cap and base may be detached, while others may be single-piece housings. Various sealing arrangements may be provided to prevent dust and other contaminants from entering the housing. Thus the housing provides a clean environment for the environmentally sensitive bearing to rotate free from contaminants while also retaining lubrication, either oil or grease, hence increasing its performance and duty cycle.

Bearing housings are usually made of grey cast iron. However, various grades of metals can be used to manufacture the same, including ductile iron, steel, stainless steel, and various types of thermoplastics and polyethylene-based plastics. The bearing element may be manufactured from 52100 chromium steel alloy (the most common), stainless steel, plastic, or bushing materials such as SAE660 cast bronze, or SAE841 oil impregnated sintered bronze, or synthetic materials.

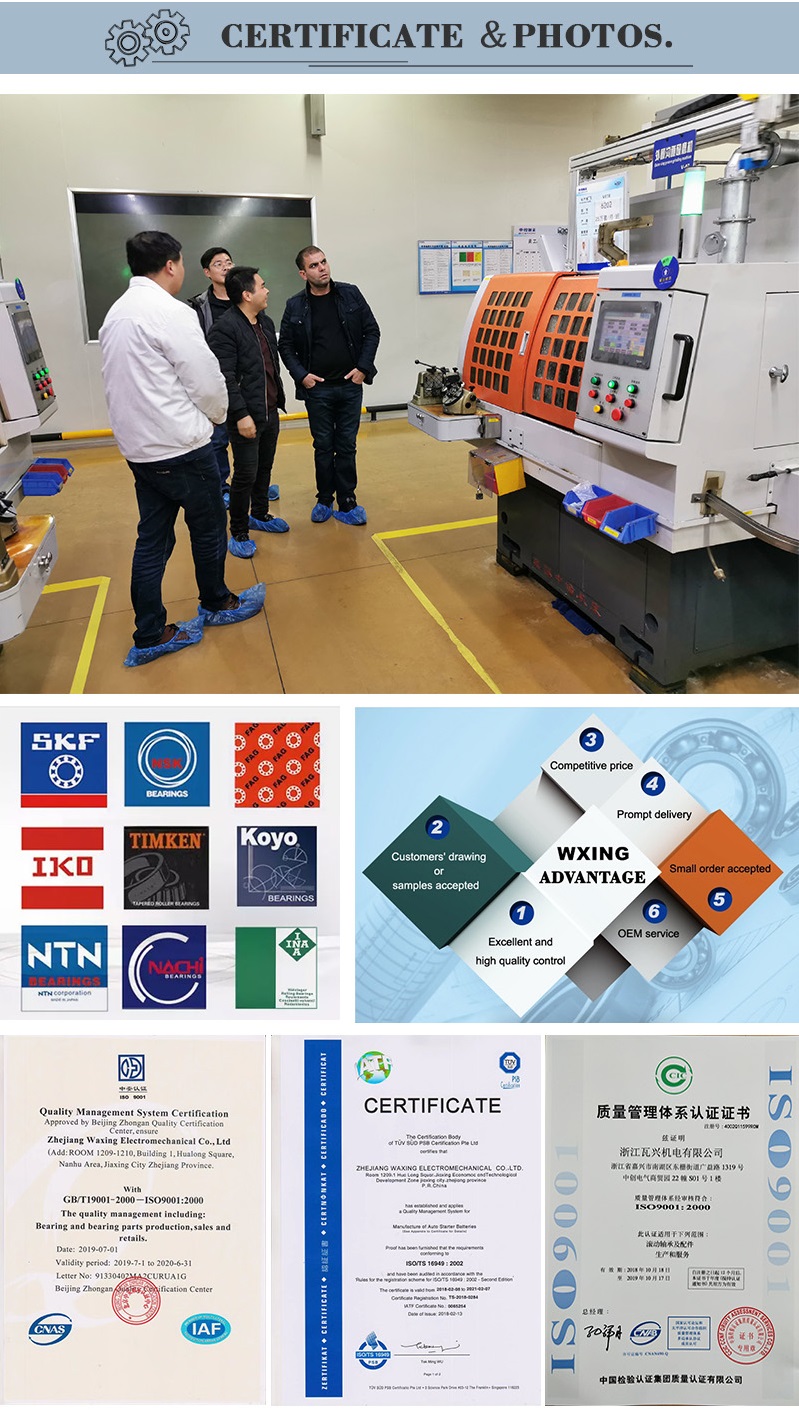

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.