Thrust roller bearing

Size range:

90 mm to 1000 mm

(4.3307 in. to 33.4646 in.)

Design Attributes:

Spherically contoured rollers, arranged in a steep angular position, accommodate high thrust loads and support moderate radial loads.

Bearing geometry and manufacturing technology result in low friction of bearing.

Internal self-alignment of bearing elements during operation compensates for shaft deflections and housing distortions caused by shock or heavy loads.

The TSR’s inherent compensation for misalignment offers equipment designers the opportunity to use weldments for housing frames instead of complex castings, which reduces machining costs.

When castings are preferred, bore alignment is less critical if spherical thrust bearings are specified.

“E” styles utilize enhanced bearing geometry allowing for higher dynamic load ratings and improved lubrication characteristics.

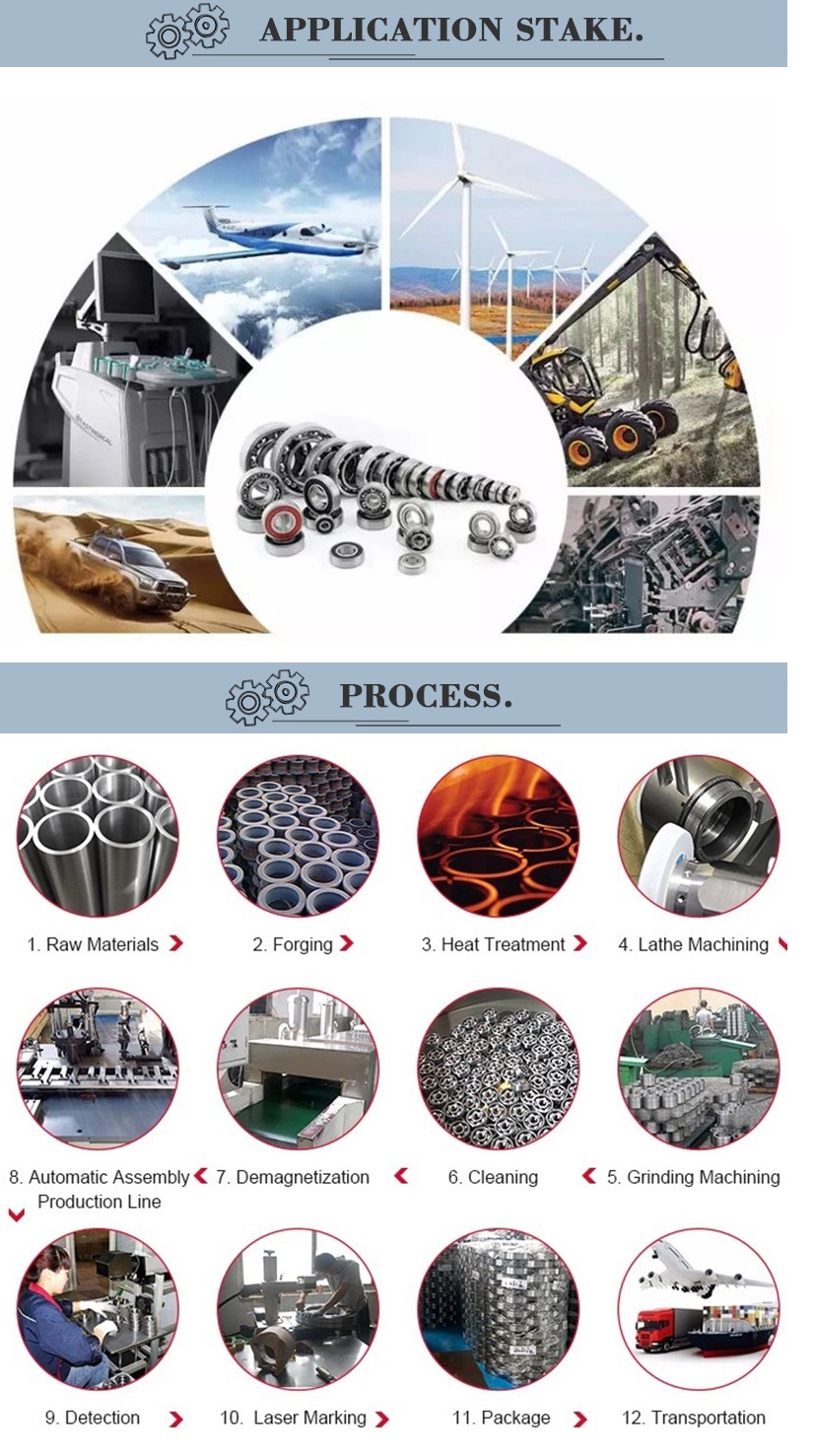

Applications:

Blowout preventers

Classifiers

Extruders

Gearboxes

Metal mill work/back-up rolls

Pre-heater fans

Pumps

Screw conveyors

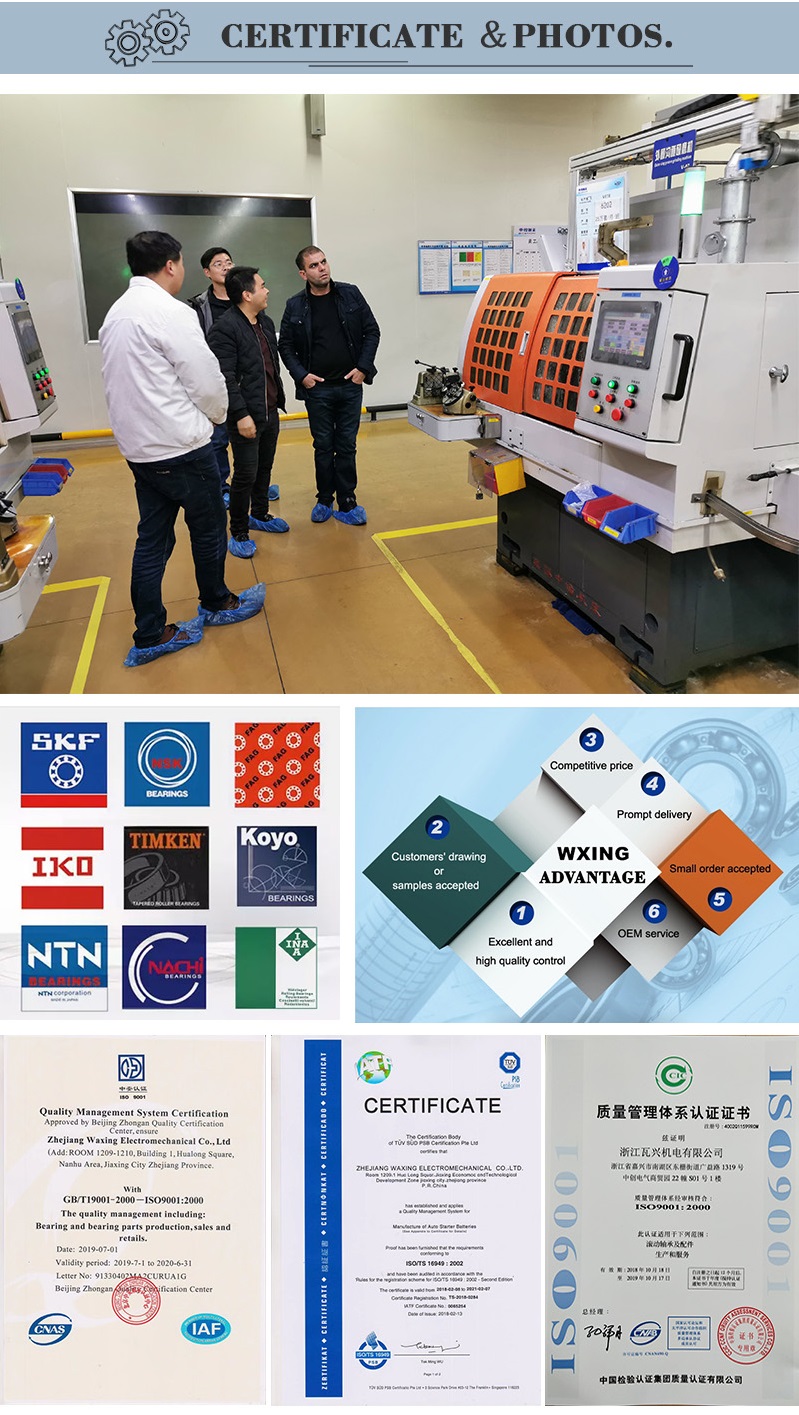

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.