Type:

Roller

Structure:

Taper

Applicable Industries:

Building Material Shops, Machinery Repair Shops, Restaurant, Home Use, Retail, Construction works , Food & Beverage Shops

Brand Name:

WXING/OEM

Model Number:

33022 3007122E

Precision Rating:

P0 P5 P6 P4

Seals Type:

open

Number of Row:

Single Row

Place of Origin:

Shandong, China

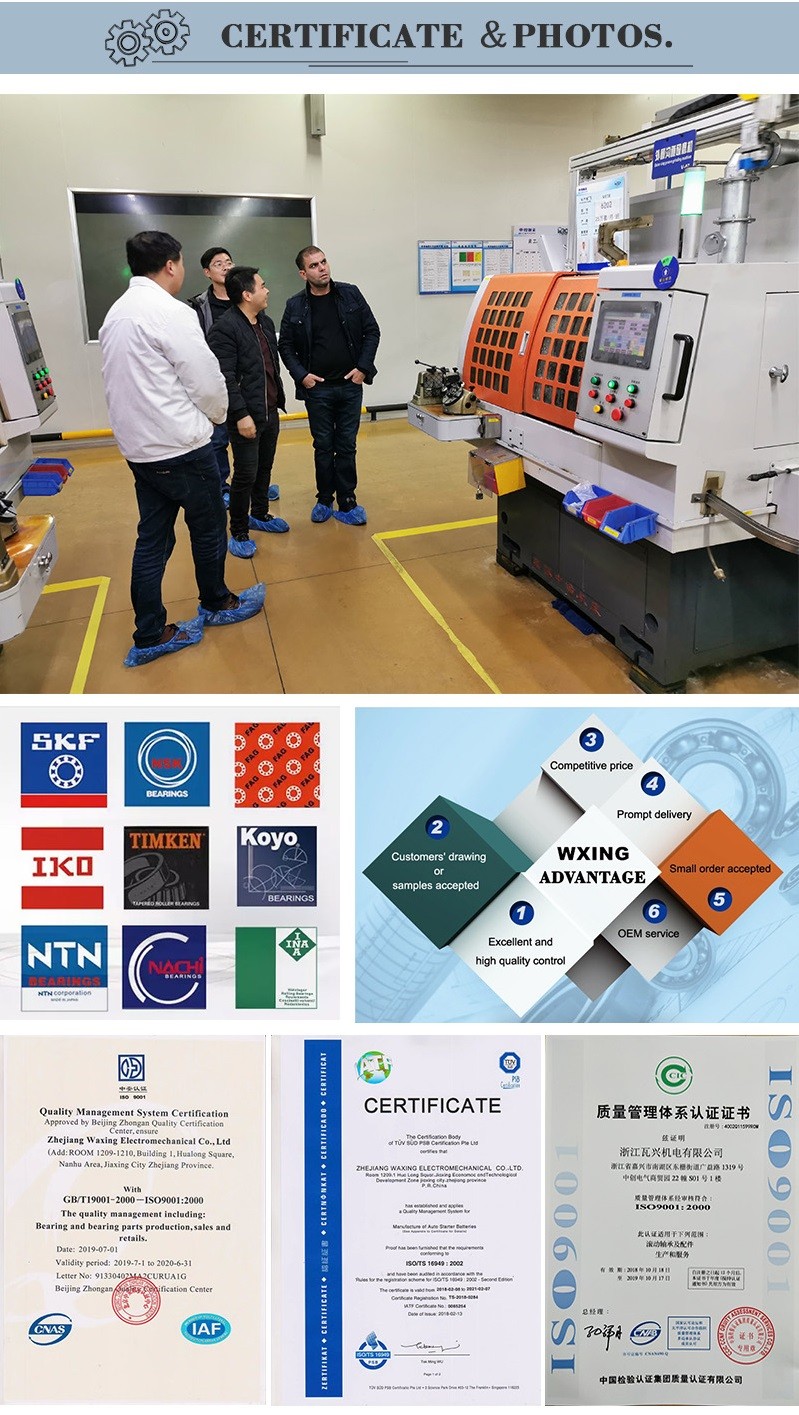

Certification:

ISO9001:2008

Material:

GCR15,GCr15SiMn,GCr18Mo

Clearance:

C2 C0 C3 C4 C5

Service:

OEM Customized Services

Application:

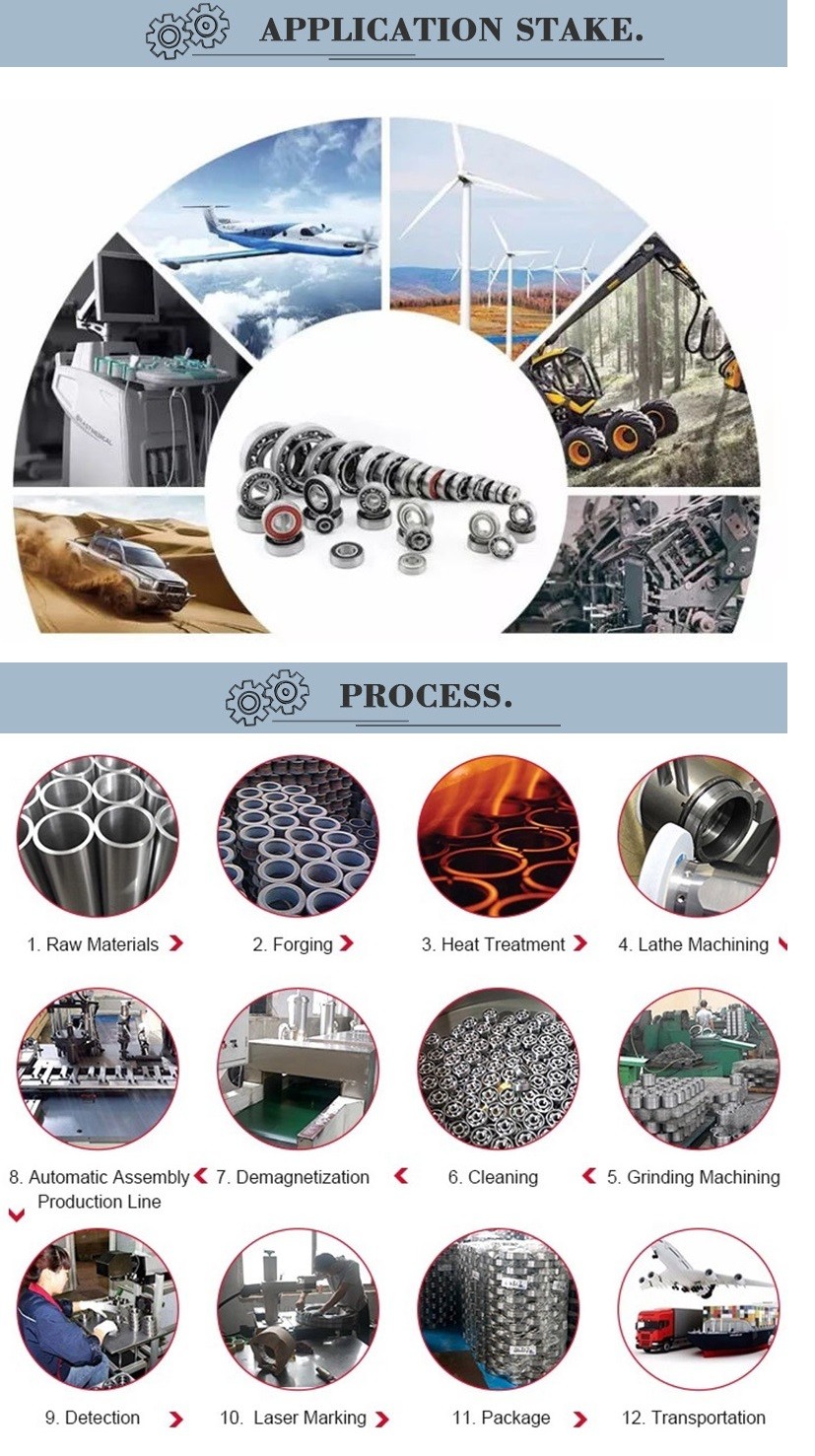

Machinery

Packaging & Delivery

Selling Units:

Single item

Single package size:

1X1X1 cm

Single gross weight:

0.056 kg

Package Type:

According to orders

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.