Structure:

Type:

Applicable Industries:

Brand Name:

Model Number:

Precision Rating:

Seals Type:

Number of Row:

Place of Origin:

Product name:

Material:

Service:

Cage:

Feature:

Vibration:

Sample:

Size:

Width:

Weight:

Supply Ability:

50000 Piece/Pieces per Week Tapered Roller Bearing 32216

Packaging Details

1. Neutral Packing

Bearing + Neutral Plastic Bag(Tube) or Neutral Box + Neutral Carton + Pallet;

2. Industrial Packing

Bearing + Industrial Kraft Paper + Carton + Pallet;

3. Commercial Packing

Bearing + Plastic Bag + Color Box + Carton + Pallet;

4. As Your Requirement.

Port

Qingdao,

High Precision Tapered Roller Bearing 32216

Product Introduction:

Product Introduction:

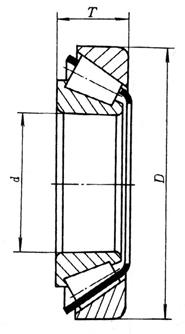

Tapered roller bearing comprised by inner ring, roller , retainer and outer ring, which can be installed separately. This kind of bearing can support heavy radial load and axial load. Due to tapered roller bearing can only transfer one-way axial load, we need to install a symmetric tapered roller bearing to transfer the opposite direction axial load. This kind of bearing include single row , double-row and four-row tapered roller bearing according to the column number of roller. The clearance of single row tapered roller bearing need a adjustment during installation. And the clearance of double-row and four-row tapered roller bearing has been adjusted according to the users' requirement and need not to adjust.

Feature:

Application:

Application:

Drawing:

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.