Quick Details

Structure:

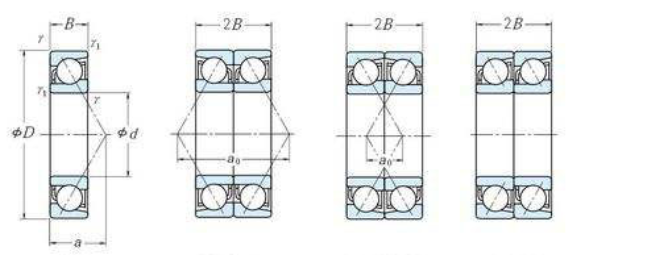

Angular Contact

Type:

Ball

Applicable Industries:

Manufacturing Plant, Machinery Repair Shops

Brand Name:

WXing Bearing

Precision Rating:

P0 P6 P5

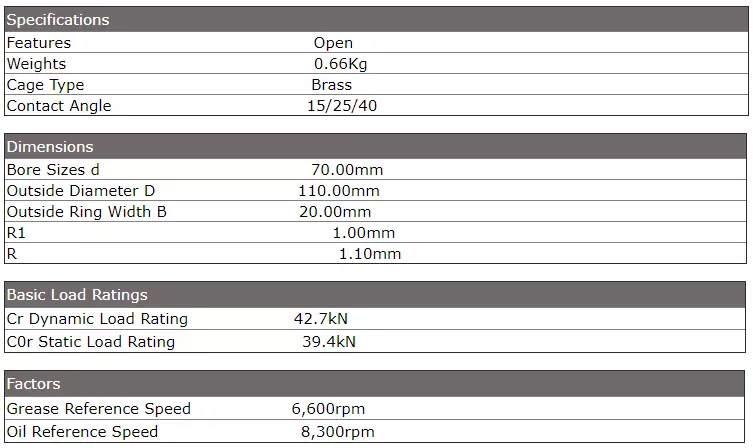

Seals Type:

Open

Number of Row:

Single Row

Place of Origin:

shandong, China

Total Width:

20.00mm

Weights:

0.66Kg

Material:

Chrome Steel GCr15

Cage Material:

Brass

Name:

7014 Angular Contact Ball Bearing

Application:

Machinery

Feature:

High Speed

Service:

OEM Customized Services

Sample:

Availabe

MOQ:

2

Supply Ability

Supply Ability:

2000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details

1.Commercial:1pc/plastic bag + color box + carton + pallet;

2.Industrial: a). plastic tube + carton + pallet; b). plastic bag + kraft paper + carton + pallet;

3.Customized packaging solutions for our customers.

Port

qingdao

Picture Example:

Lead Time :

Quantity(Pieces) 1 - 100 101 - 1000 >1000

Est. Time(days) 7 15 To be negotiated

Product Description

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.