Quick Details

Structure:

Deep Groove

Type:

Ball

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Bore Size:

2 - 395 mm

Model Number:

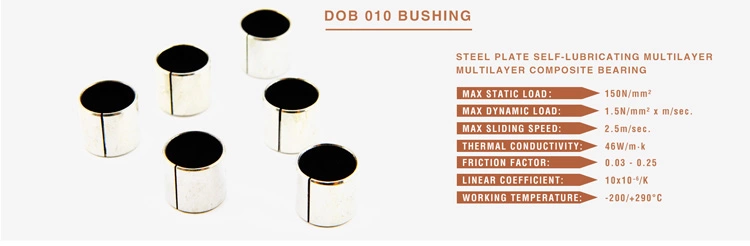

DOB010

Precision Rating:

DIN1494

Seals Type:

Open

Number of Row:

Single Row

Place of Origin:

Shandong, China

Bearing Type::

Plain

Plain Bearing Type::

Sleeve ; Flange ; Washer

For Load Direction::

Radial

Shell Material::

Steel ; Bronze

Sliding Material::

PTFE plastic ; Bronze

Standards::

DIN1494

Dynamic Radial Load Capacity::

390lbs~3100lbs @ 60rpm

Lubrication::

Not Required

For Shaft Type:

Round

| Oilless Sliding Self Lubricating Products | |||

| Material Backing Base: | Steel Backing / Low Carbon Steel / Stainless Steel / Brass | ||

| Material Porous Layer: | SAE841;ASTM B438-70 GR1 SintA50 ; CuSn6-6-3;CuSn8/3 | ||

| Material Sliding Layer: | PTFE+Pb ; PTFE / non lead ; POM ; Resin with Graphite | ||

| Working Temperature: | -195ºC ~ +280ºC | Static Max Load: | 250N/mm2 |

| Dynamic Max Load: | 140N/mm2 | Certification | ISO9001:2015 |

| Oscillating Max.Load: | 60N/mm2 | Warranty | 12 Months |

| PV Limit ( *Dry): | 3.6N/mm2. m/s | PV Limit (*Oil): | 50N/mm2. m/s |

| Friction Coeff. | 0.03~0.20 | Speeds Limit (*Dry) | 2.0 m/s |

| Speeds Limit ( *Oil): | 5.0 m/s | Tolerance Range: | DIN1494 ; Go/No Go |

| Coeff.of linear expansion | 27x10-6perºC | Basic Shape: | Cyclinder ; Flange ;Washer |

Dry-Running Sleeve Bearing with Steel Shell made by:

PTFE-Lined TIN Bronze, for Shaft Diameter Diameter from 1.5mm to 300mm .A metal shell adds strength to these bearings.

PTFE-lined bronze bearings with steel shell have a slit running along the length of the bearing that allows you to slip fit them onto a shaft.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. Please contact DALON for more details

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.