Related Products

Quick Details:

| Type: | Roller | Brand Name: | WXING |

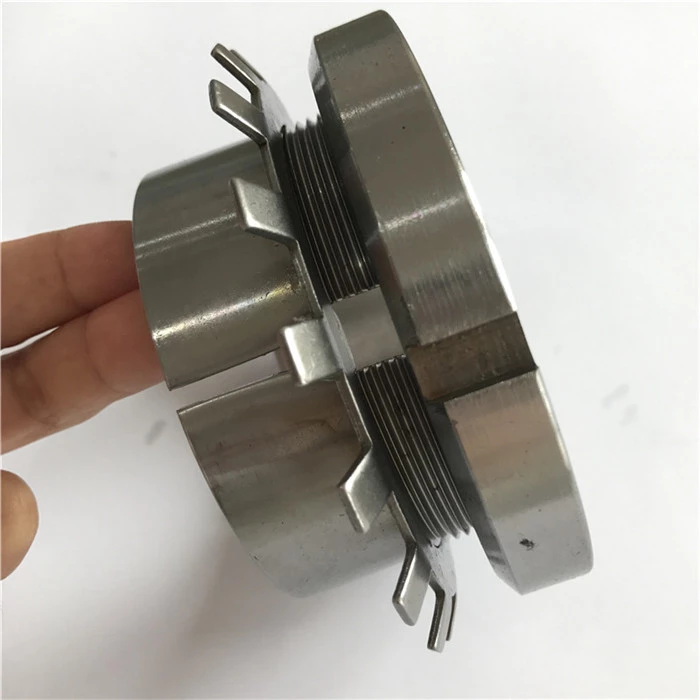

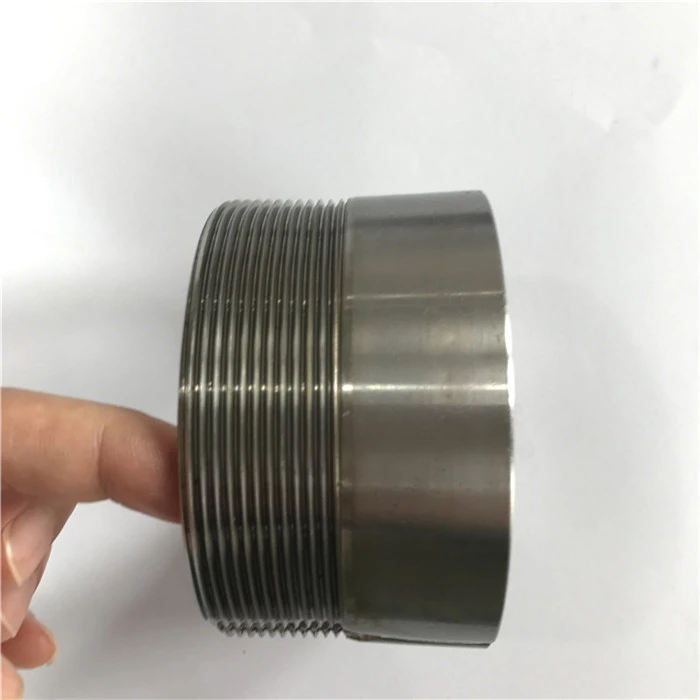

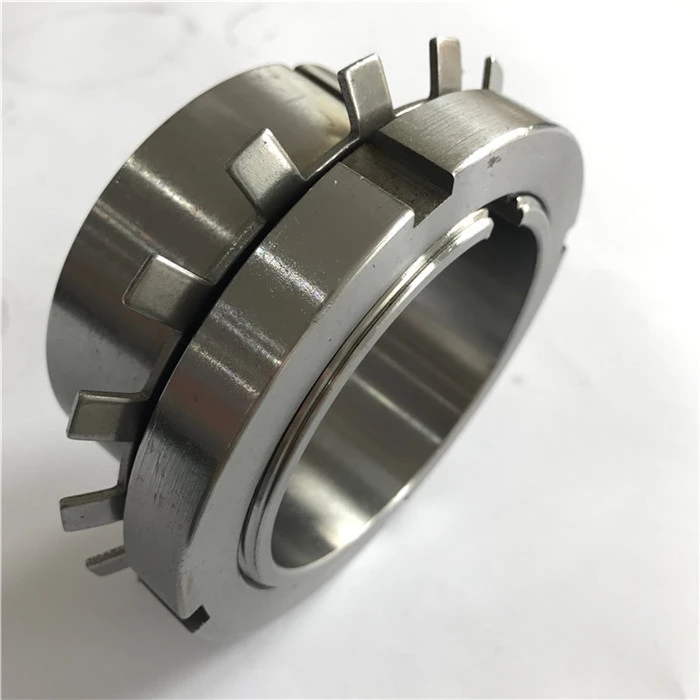

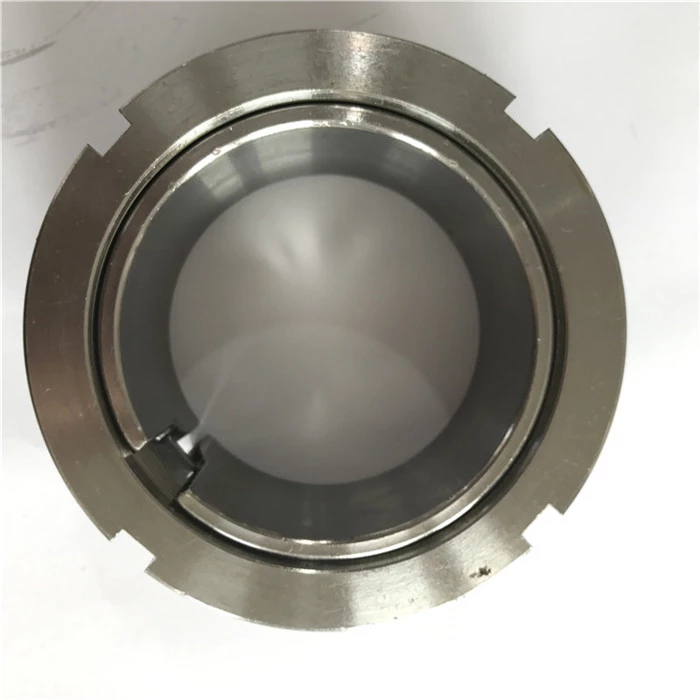

| Structure: | Taper | Product name: | Adapter sleeve bearing for plain or stepped shafts |

| Applicable Industries: | Building Material Shops, Machinery Repair Shops, Farms | Material: | Chrome Steel/GCr15 |

| Feature: | Stable Performance:low Voice | Stock: | Rich |

| Place of Origin: | Shandong, China | Model: | H310 |

| Sample: | Available |

Packaging & Delivery

Packaging Details

1. Industrial package: carton+wooden pallet

2. Individual package: individual paper box+ carton+ wooden pallet for bearing adapter sleeve H316 H312 H318 H320 H308 H310 sleeve bearing

Port

qingdao,guangzhou,Shanghai

Product information

| Model number | H310 |

| Material | Chrome Steel/GCr15 |

| Number of row | Single Row |

| Precision | P0 P6 P5 P4 P2 |

| STOCK | Great Supplying Ability |

| Precision rating | ABCE-1 ABCE-3 ABCE-5 ABCE-7 |

| Vibration | V1 V2 V3 V4 |

| Clearance | C0 C2 C3 C4 C5 |

| Delivery Detail | 2-5 days upon receipt of deposit or according to your requirements |

| Shipping | Express ,Air ,Sea Shipping |

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.