Brand Name:

Bore Size:

Outside Diameter:

Model Number:

Precision Rating:

Seals Type:

Number of Row:

Place of Origin:

Product name:

Cage:

Clearance:

Vibrating Level:

Main Market:

Service:

Material:

Certificates:

samples/stock:

Packing details:

Supply Ability:

200000 Set/Sets per Year DKF bearing RN307 502307H cylindrical roller bearing 35*68.2*21m

Packaging Details

DKF bearing RN307 502307H cylindrical roller bearing 35*68.2*21mm

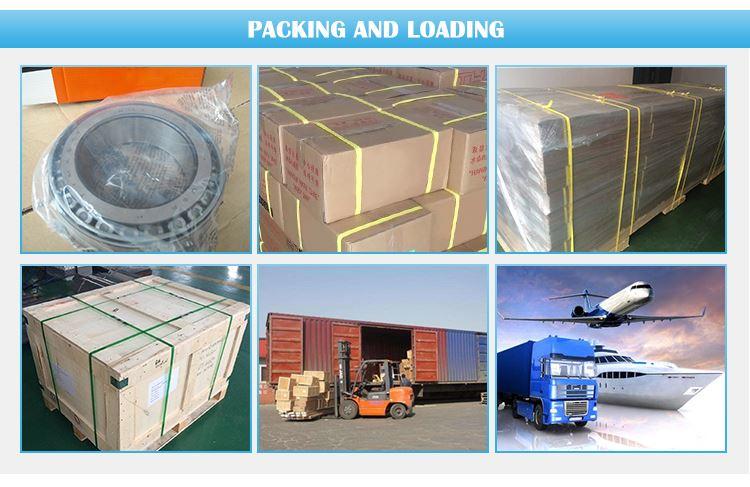

Package details 1. Neutral Package: Plastic Bag + Carton + Pallet; 2. Commercial Package: Plastic Bag + Box + Carton + Pallet; 3. As the clients' requirement.

Port

Qingdao,

specification

product name | RN307 502307H cylindrical roller bearing 35*68.2*21mm |

Brand name | WXing or OEM |

Model number | RN307 502307H |

cage material | nylon , steel , brass. |

Precision | P0 P5 P6 P4 P2 |

Material | Chrome steel, stainless steel |

Service | OEM service |

Precision | ABEC3 ABEC5 ABEC7 ABEC9 |

Seal Type | N,NU,NJ,NNU,NUP,Seal, Open, E, ECM , ECP |

Vibration Level Codes | Z1V1 , Z2V2 , Z3V3 , Z4V4, |

Quality standard | ISO9001 |

Certificate | SGS & ROHS |

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.