Related Products

Quick Details:

<

| Type: | Roller, roller |

| Structure: | Cylindrical, cylindrical |

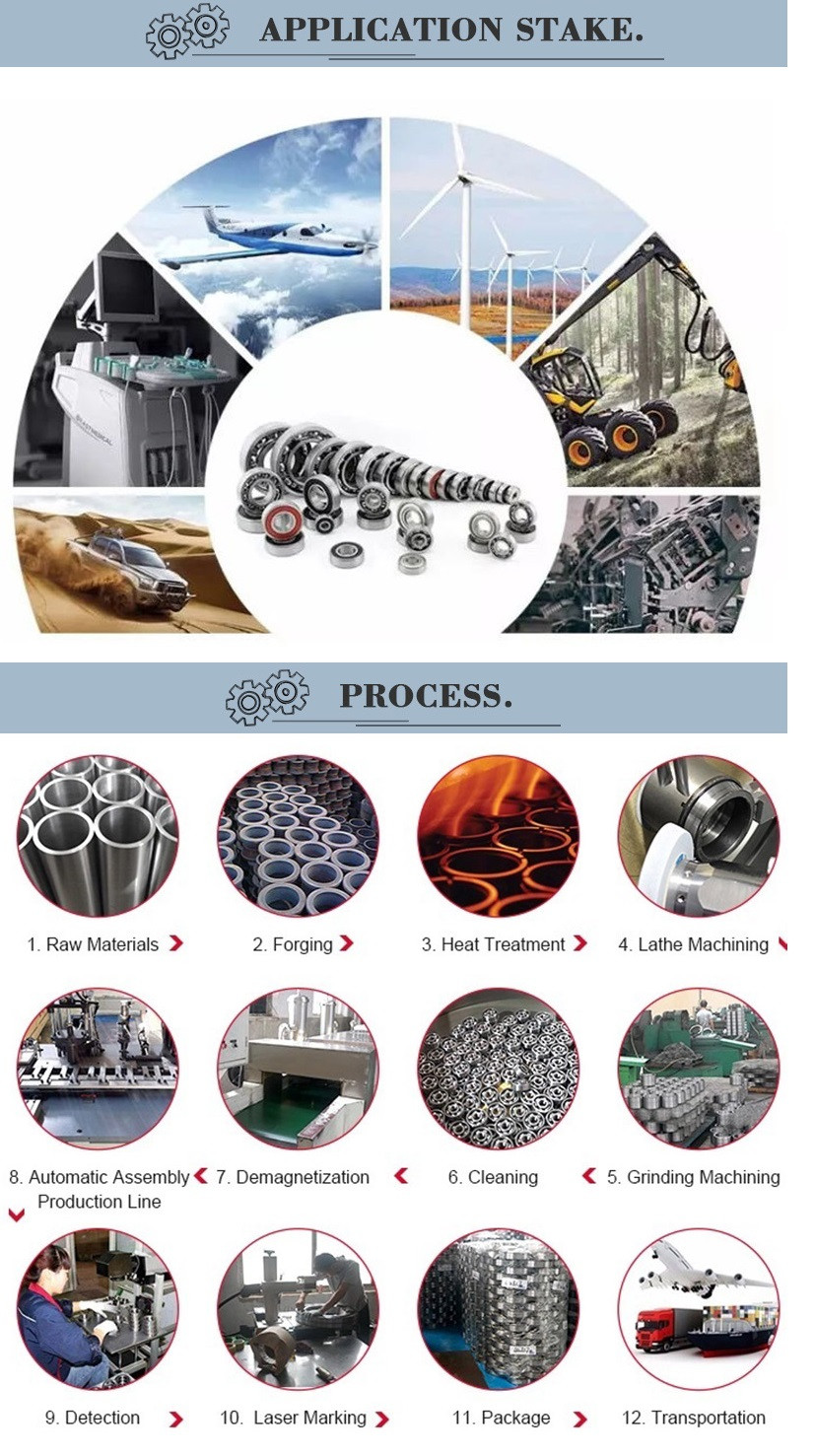

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

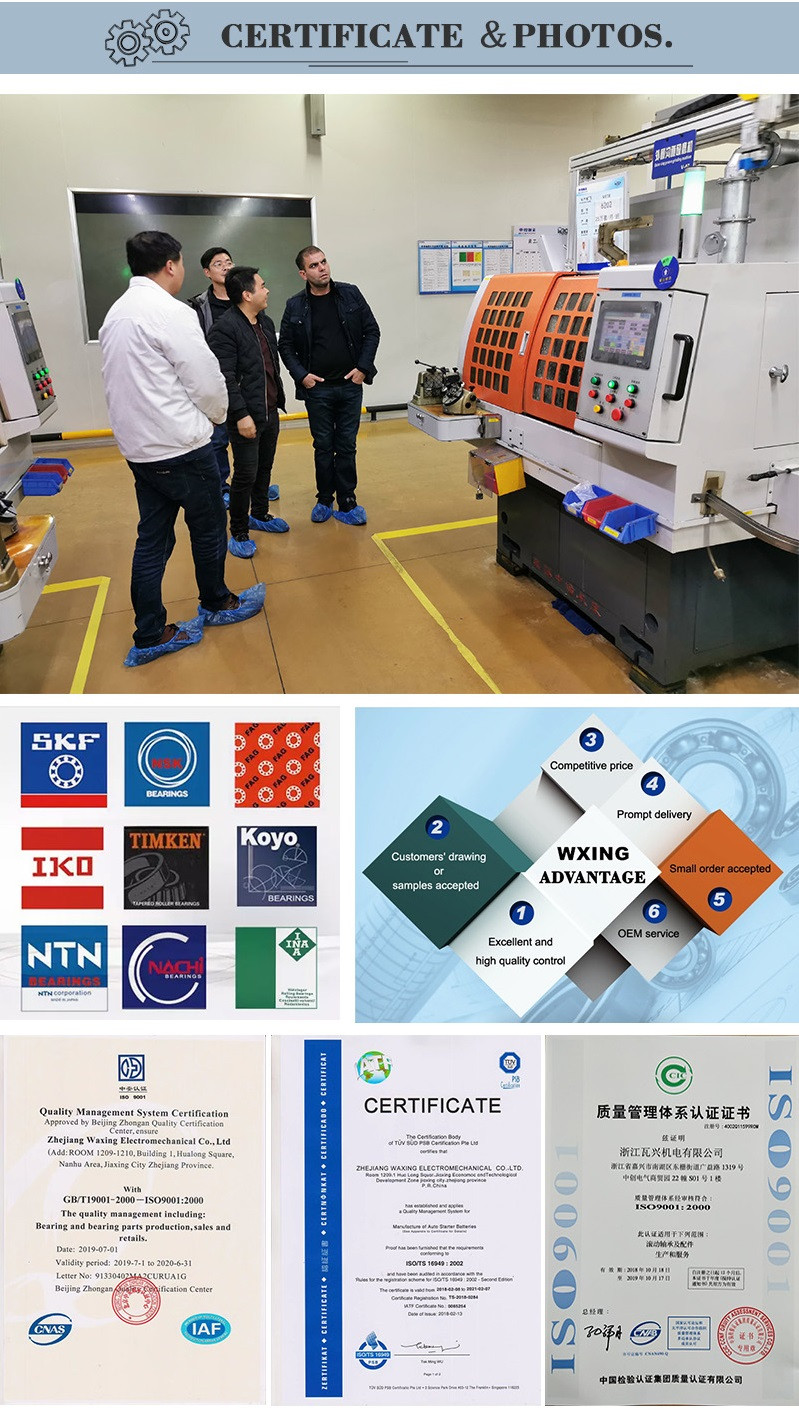

| Brand Name: | WXING |

| Model Number: | NJ2305E |

| Precision Rating: | P0.P6.P5.P4.P2 |

| Number of Row: | Single Row |

| Place of Origin: | China |

| Size: | 25*62*24mm |

| Certificate: | ISO9001 |

| Service: | OEM Service.Design Service |

| Material: | Chrome Steel/GCr15;Stainless Steel;Carbon steel |

| Clearance: | C2 C0 C3 C4 C5 |

| Tolerance: | ABEC-1 ABEC-2 ABEC-3 ABEC-5 ABEC-7 |

| Feature: | Low Noise, Long Life |

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.