Usage:

Automobile

Size:

35x64x37mm

Car Make:

Automobile

OE NO.:

DAC3564A-1

Place of Origin:

Shandong, China

Brand Name:

WXING

Model Number:

BAH-0042 / BAH 0042

Product Name:

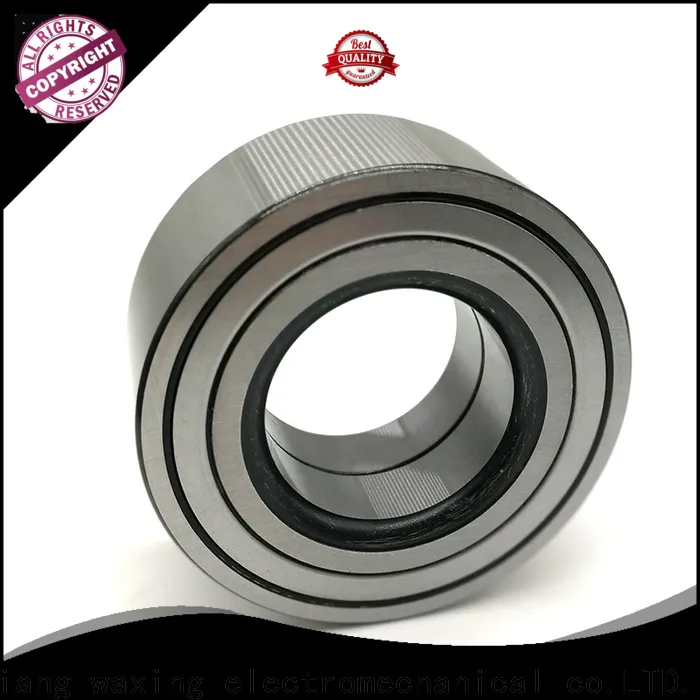

35x64x37mm Truck Wheel Bearing BAH-0042

Inner Diameter:

35 mm

Outer Diameter:

64 mm

Width:

37 mm

Weight:

0.467 Kg

Application:

Auto bearing

Material:

Chromel steel (Gcr15)

Sample:

Available / Free

Type:

Angular Contact Ball Bearing

row number:

2

Product detail

Product Name | 35x64x37mm Truck Wheel Bearing BAH-0042 DAC3564A-1BAH 0042 |

Brand | WXING/ OEM |

Model Number | BAH-0042 |

Ring Material | Chrome steel |

Precision | P0, P6, P5, or as requested |

Vibration | ZV1, ZV2, ZV3, or as requested |

Clearance | C0,C2,C3, or as requested |

Features | Accommodate misalignment ,High load carrying capacity ,Long service life ,Low friction ,Excellent light load performance ,Low noise,Robust . |

Quality Control Process | 1.Assembly |

2.Windage test | |

3.Cleaning | |

4.Rotary test | |

5.Greasing and gland | |

6.Noise inspection | |

7.Appearance inspection | |

8.Rust prevention | |

9.Product packaging | |

Application | Automobile |

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.