Related Products

Quick Details:

| Type: | PC300-8 Slewing ring | Product name: | Excavator PC300-8 Slewing ring / Swing Bearing 207-25-61100 Swing Circle assy fit for Excavator PC300-8; PC300LC-8 |

| Structure: | Four Point Contact | Place of Origin: | Shandong, China |

| Brand Name: | WXING or OEM | Hardness: | 55-62HRC, Gear and Entire |

| Material: | 42CrMo, 50Mn,Steel 45# | Outside Diameter: | 500 - 5000 mm |

| Gear Options: | Internal Gear Only | Feature: | Four Point Contact |

| Bore Size: | 200 - 5000 mm | Condition: | 100%New Durable Long life |

| Part name: | 207-25-61100 Swing Circle assy |

| Product Name | Slewing Bearing/Swing Bearing/Swing Circle/Swing Ring |

| Material | 50Mn/42CrMo |

| Size | OEM, As Customer's Requirements |

| Model | Non-Gear, External Gear, Internal Gear |

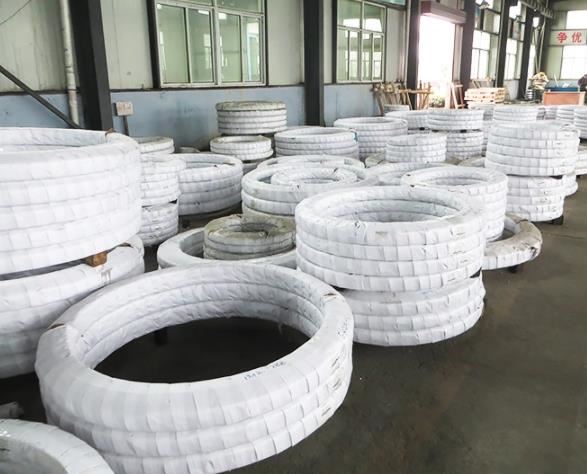

| Package | Plywood Case, Pallet |

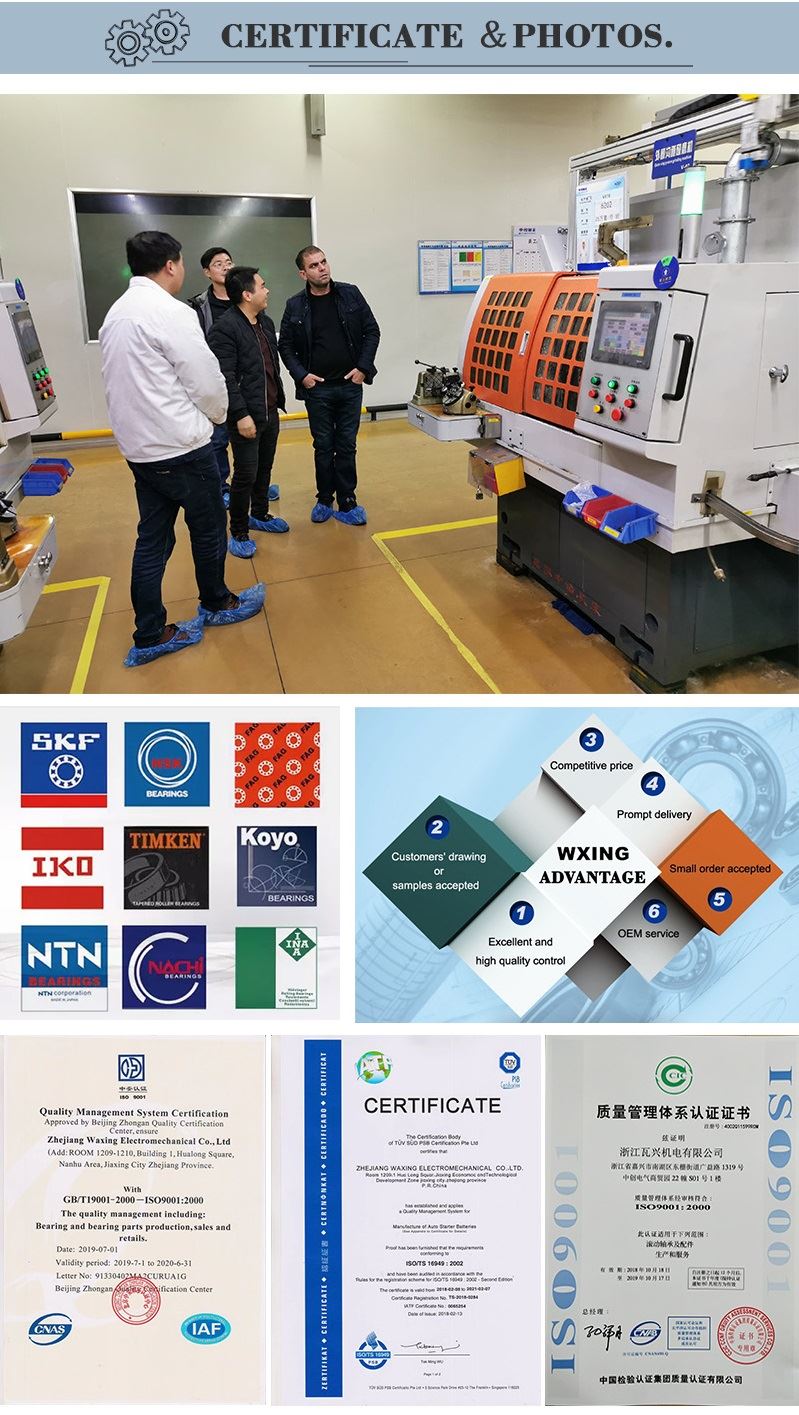

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.