Structure:

Type:

Applicable Industries:

Bore Size:

Model Number:

Precision Rating:

Seals Type:

Number of Row:

Place of Origin:

keyword:

type:

thin section ball bearing:

size:

material:

production name:

Material:

Application:

Package:

Service:

Supply Ability:

800000 Piece/Pieces per Month Thin section ball bearing KA035XP0

Packaging Details

(1) TUBE package(industry package) +pallet

(2)Commercial packing: 1pc/plastic bag + color box + carton + pallets

(3) As the clients' requirements

Port

qingdao

4-point contact ball bearing 88.9*101.6*6.350mm thin wall Thin section ball bearing KA035XP0

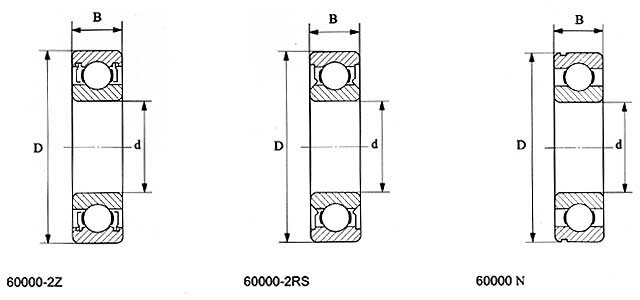

picture show:

Thin section ball bearing KD065XP0

size: 6.5*7.5*0.5mm

(1) high precision and low price

(2)good quality and fast delievery

thin section ball bearing KD065XP0

| Model | Dimension | |||||

| d | D | Width | L1 | L2 | ||

| inch | ||||||

| KA020XP0 | 2.00 | 2.50 | 0.25 | 2.19 | 2.31 | |

| KA025XP0 | 2.50 | 3.00 | 0.25 | 2.69 | 2.81 | |

| KA030XP0 | 3.00 | 3.50 | 0.25 | 3.19 | 3.31 | |

| KA035XP0 | 3.50 | 4.00 | 0.25 | 3.69 | 3.81 | |

| KA040XP0 | 4.00 | 4.50 | 0.25 | 4.19 | 4.31 | |

| KA042XP0 | 4.25 | 4.75 | 0.25 | 4.44 | 4.56 | |

| KA045XP0 | 4.50 | 5.00 | 0.25 | 4.69 | 4.81 | |

| KA047XP0 | 4.75 | 5.25 | 0.25 | 4.94 | 5.06 | |

| KA050XP0 | 5.00 | 5.50 | 0.25 | 5.19 | 5.31 | |

| KA055XP0 | 5.50 | 6.00 | 0.25 | 5.69 | 5.81 | |

| KA060XP0 | 6.00 | 6.5 | 0.25 | 6.19 | 6.31 | |

| KA065XP0 | 6.50 | 7.00 | 0.25 | 6.69 | 6.81 | |

| KA070XP0 | 7.00 | 7.50 | 0.25 | 7.19 | 7.31 | |

| KA075XP0 | 7.50 | 9.00 | 0.25 | 7.69 | 7.81 | |

| KA080XP0 | 8.00 | 8.50 | 0.25 | 8.19 | 8.31 | |

| KA090XP0 | 9.00 | 9.50 | 0.25 | 9.19 | 9.31 | |

| KA100XP0 | 10.00 | 10.50 | 0.25 | 10.19 | 10.31 | |

| KA110XP0 | 11.00 | 11.50 | 0.25 | 11.19 | 11.31 | |

| KA120XP0 | 12.00 | 12.50 | 0.25 | 12.19 | 12.31 | |

| KB020XP0 | 2.00 | 2.63 | 0.31 | 2.23 | 2.39 | |

| KB025XP0 | 2.50 | 3.13 | 0.31 | 2.73 | 2.89 | |

| KB030XP0 | 3.00 | 3.63 | 0.31 | 3.23 | 3.39 | |

| KB035XP0 | 3.50 | 4.13 | 0.31 | 3.73 | 3.89 | |

| KB040XP0 | 4.00 | 4.63 | 0.31 | 4.23 | 4.39 | |

| KB042XP0 | 4.25 | 4.88 | 0.31 | 4.48 | 4.64 | |

| KB045XP0 | 4.50 | 5.13 | 0.31 | 4.73 | 4.89 | |

| KB047XP0 | 4.75 | 5.38 | 0.31 | 4.98 | 5.14 | |

| KB050XP0 | 5.00 | 5.63 | 0.31 | 5.23 | 5.39 | |

| KB055XP0 | 5.50 | 6.13 | 0.31 | 5.73 | 5.89 | |

| KB060XP0 | 6.00 | 6.63 | 0.31 | 6.23 | 6.39 | |

| KB065XP0 | 6.50 | 7.13 | 0.31 | 6.73 |

Waxing ball bearing parts has to go through a secondary surface operation process which mainly includes finish plating, anodizing, powder coating, and heat treatment.

During the development of Waxing best ball bearings, the interface with the device issue is taken into consideration with the purpose of reducing the tiny air gaps between the component and the product.

Much advanced quality inspection equipment is used in Waxing ball bearing parts production. It is finely handled by the coordinate measuring machine (CMM), caliper, microcaliper, gauge, and pass meter.

During the production of Waxing best ball bearings, the accuracy of machining and grinding, surface roughness, concentricity, and verticality are all strictly scrutinized to guarantee high quality.

During the developing of Waxing ball bearing parts, several important factors are considered such as sink level requirements, component level requirements, system level requirements, and chassis level requirements, to achieve the optimized heat transfer effect.

The product has good strength. During the production, it is finely welded and die-casted to ensure its physical strength.

Product Message

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Chat Online

编辑模式下无法使用

Leave Your Message

inputting...

Thanks for your message, we will reply you soon in our working time!

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly. | |