Structure:

Type:

Applicable Industries:

Bore Size:

Model Number:

Precision Rating:

Seals Type:

Number of Row:

Place of Origin:

keyword:

type:

thin section ball bearing:

size:

material:

production name:

Material:

Application:

Package:

Service:

Supply Ability:

800000 Piece/Pieces per Month Thin section ball bearing KA035XP0

Packaging Details

(1) TUBE package(industry package) +pallet

(2)Commercial packing: 1pc/plastic bag + color box + carton + pallets

(3) As the clients' requirements

Port

qingdao

4-point contact ball bearing 88.9*101.6*6.350mm thin wall Thin section ball bearing KA035XP0

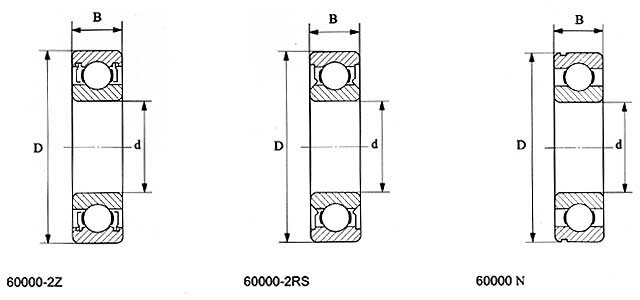

picture show:

Thin section ball bearing KD065XP0

size: 6.5*7.5*0.5mm

(1) high precision and low price

(2)good quality and fast delievery

thin section ball bearing KD065XP0

| Model | Dimension | |||||

| d | D | Width | L1 | L2 | ||

| inch | ||||||

| KA020XP0 | 2.00 | 2.50 | 0.25 | 2.19 | 2.31 | |

| KA025XP0 | 2.50 | 3.00 | 0.25 | 2.69 | 2.81 | |

| KA030XP0 | 3.00 | 3.50 | 0.25 | 3.19 | 3.31 | |

| KA035XP0 | 3.50 | 4.00 | 0.25 | 3.69 | 3.81 | |

| KA040XP0 | 4.00 | 4.50 | 0.25 | 4.19 | 4.31 | |

| KA042XP0 | 4.25 | 4.75 | 0.25 | 4.44 | 4.56 | |

| KA045XP0 | 4.50 | 5.00 | 0.25 | 4.69 | 4.81 | |

| KA047XP0 | 4.75 | 5.25 | 0.25 | 4.94 | 5.06 | |

| KA050XP0 | 5.00 | 5.50 | 0.25 | 5.19 | 5.31 | |

| KA055XP0 | 5.50 | 6.00 | 0.25 | 5.69 | 5.81 | |

| KA060XP0 | 6.00 | 6.5 | 0.25 | 6.19 | 6.31 | |

| KA065XP0 | 6.50 | 7.00 | 0.25 | 6.69 | 6.81 | |

| KA070XP0 | 7.00 | 7.50 | 0.25 | 7.19 | 7.31 | |

| KA075XP0 | 7.50 | 9.00 | 0.25 | 7.69 | 7.81 | |

| KA080XP0 | 8.00 | 8.50 | 0.25 | 8.19 | 8.31 | |

| KA090XP0 | 9.00 | 9.50 | 0.25 | 9.19 | 9.31 | |

| KA100XP0 | 10.00 | 10.50 | 0.25 | 10.19 | 10.31 | |

| KA110XP0 | 11.00 | 11.50 | 0.25 | 11.19 | 11.31 | |

| KA120XP0 | 12.00 | 12.50 | 0.25 | 12.19 | 12.31 | |

| KB020XP0 | 2.00 | 2.63 | 0.31 | 2.23 | 2.39 | |

| KB025XP0 | 2.50 | 3.13 | 0.31 | 2.73 | 2.89 | |

| KB030XP0 | 3.00 | 3.63 | 0.31 | 3.23 | 3.39 | |

| KB035XP0 | 3.50 | 4.13 | 0.31 | 3.73 | 3.89 | |

| KB040XP0 | 4.00 | 4.63 | 0.31 | 4.23 | 4.39 | |

| KB042XP0 | 4.25 | 4.88 | 0.31 | 4.48 | 4.64 | |

| KB045XP0 | 4.50 | 5.13 | 0.31 | 4.73 | 4.89 | |

| KB047XP0 | 4.75 | 5.38 | 0.31 | 4.98 | 5.14 | |

| KB050XP0 | 5.00 | 5.63 | 0.31 | 5.23 | 5.39 | |

| KB055XP0 | 5.50 | 6.13 | 0.31 | 5.73 | 5.89 | |

| KB060XP0 | 6.00 | 6.63 | 0.31 | 6.23 | 6.39 | |

| KB065XP0 | 6.50 | 7.13 | 0.31 | 6.73 |

Alternatives are provided for the types of Waxing angular contact ball bearing assembly. Coil, spring, latex, foam, futon, etc. are all choices and each of these has its own varieties.

Waxing angular contact ball bearing assembly is manufactured according to the regulations for electric appliances. Its Electro Magnetic Compatibility (EMC), ability to resist electric arc, overload protection, and heat dissipation capability have been assessed to at a qualified level.

Waxing stainless ball bearings has passed several most important tests. It will be tested by the third-party testing organization regarding its nominal voltage and current, short-circuit breaking capacity, electrical lifespan, and mechanical lifespan.

Waxing angular contact ball bearing assembly involves different manufacturing processes. These processes may include cold stamping, plastic pressing, insulation, resistance welding, and electrical component heat treatment.

Waxing stainless ball bearings is of flexible design. It is custom-designed and manufactured with a precise product in mind, and its format is also depended on the location, product, and desired objective.

The product features vibration resistance. By reducing the amplitude and frequency of the vibrational waves, it outwardly disperses the energy caused by vibrations.

Product Message

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Chat Online

编辑模式下无法使用

Leave Your Message

inputting...

Thanks for your message, we will reply you soon in our working time!

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly. | |