CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

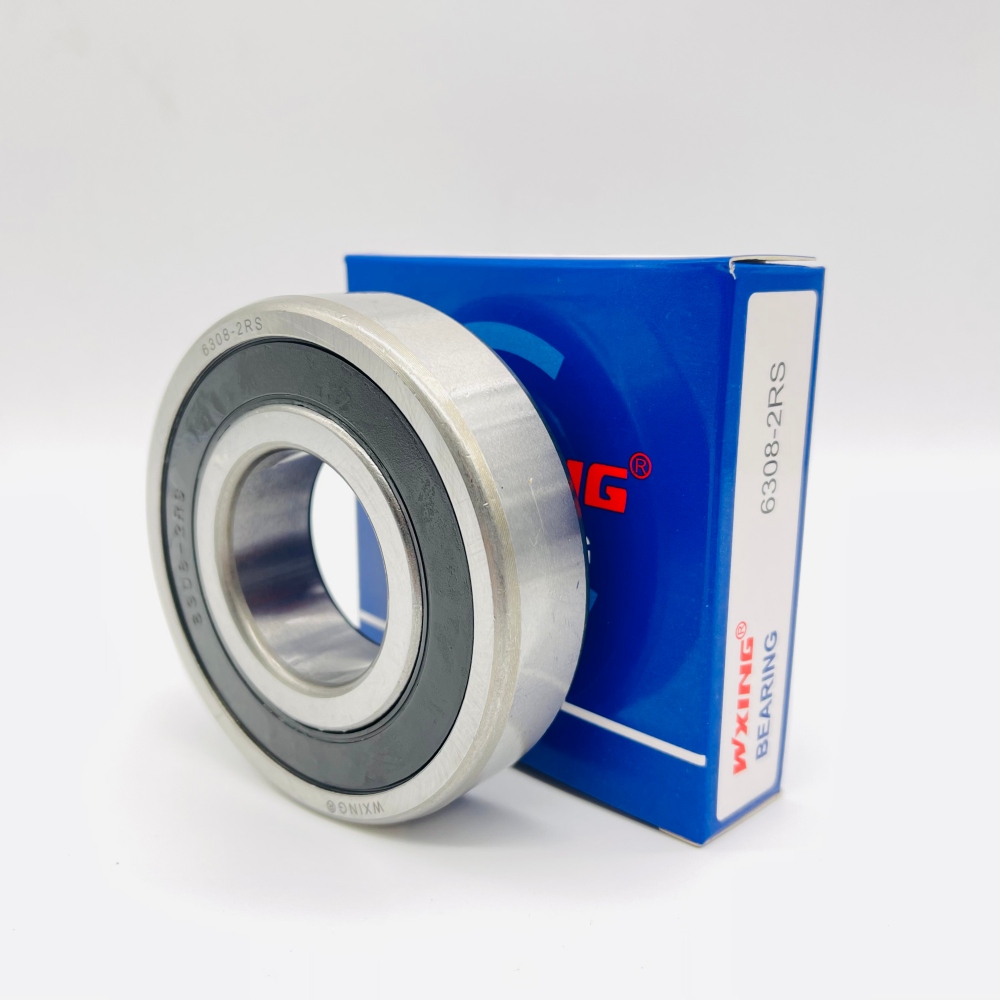

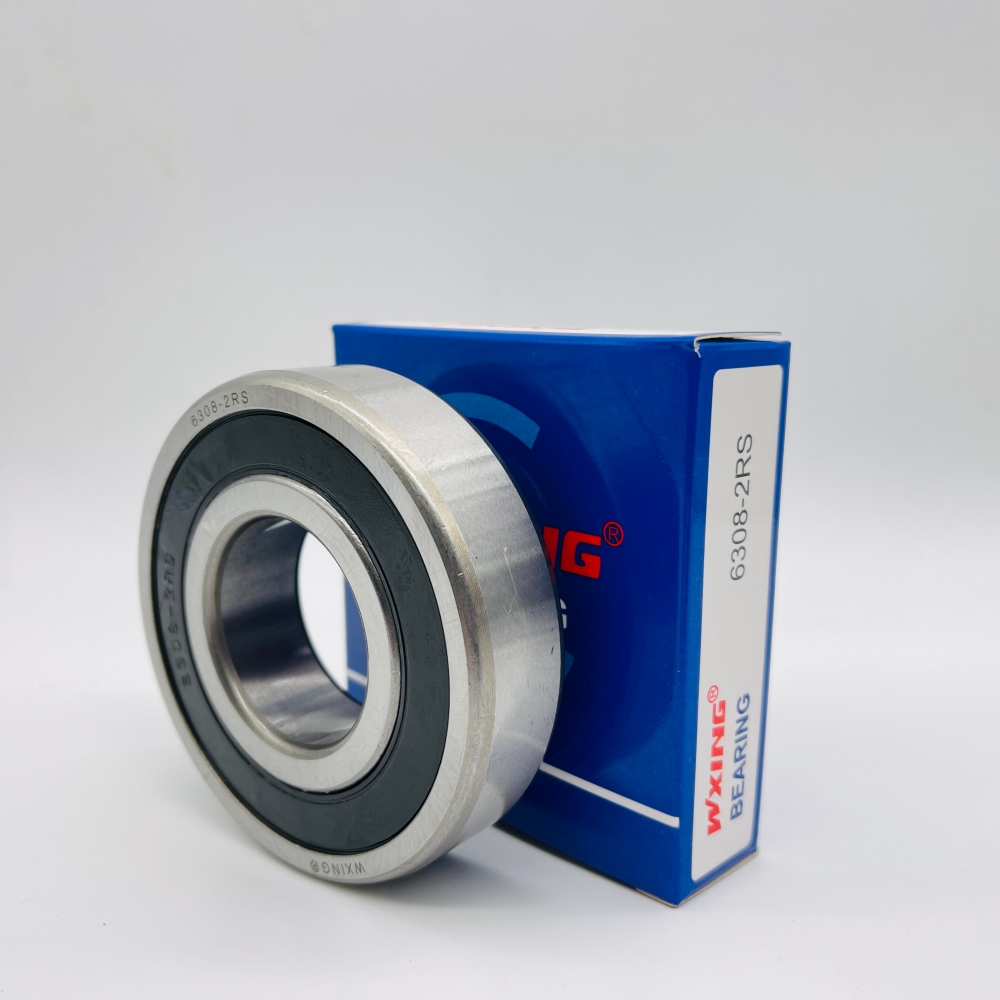

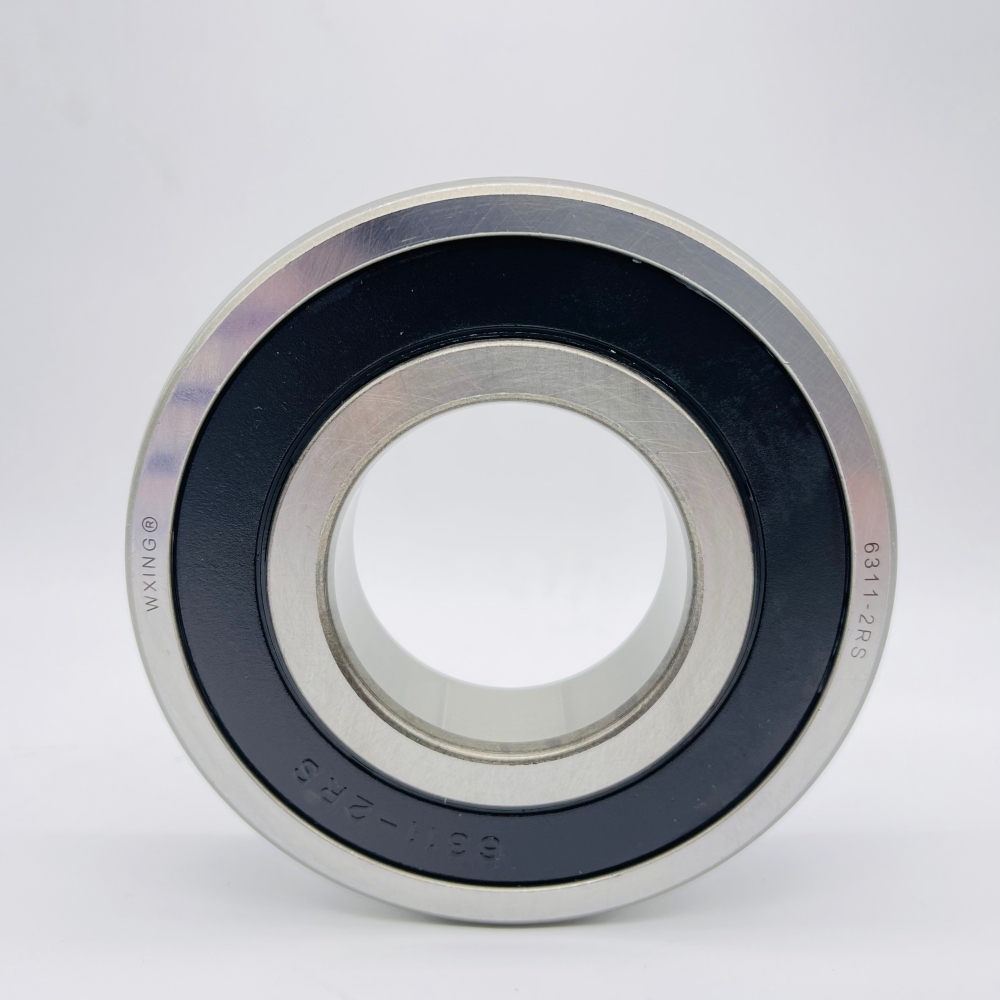

The role of the wheel is essential for the car to be able to drive. Whether the bearing in the wheel is good or not will directly affect the running effect of the tire. So if it is a deep groove ball bearing, how to judge it from the appearance? The following editor organizes five aspects :

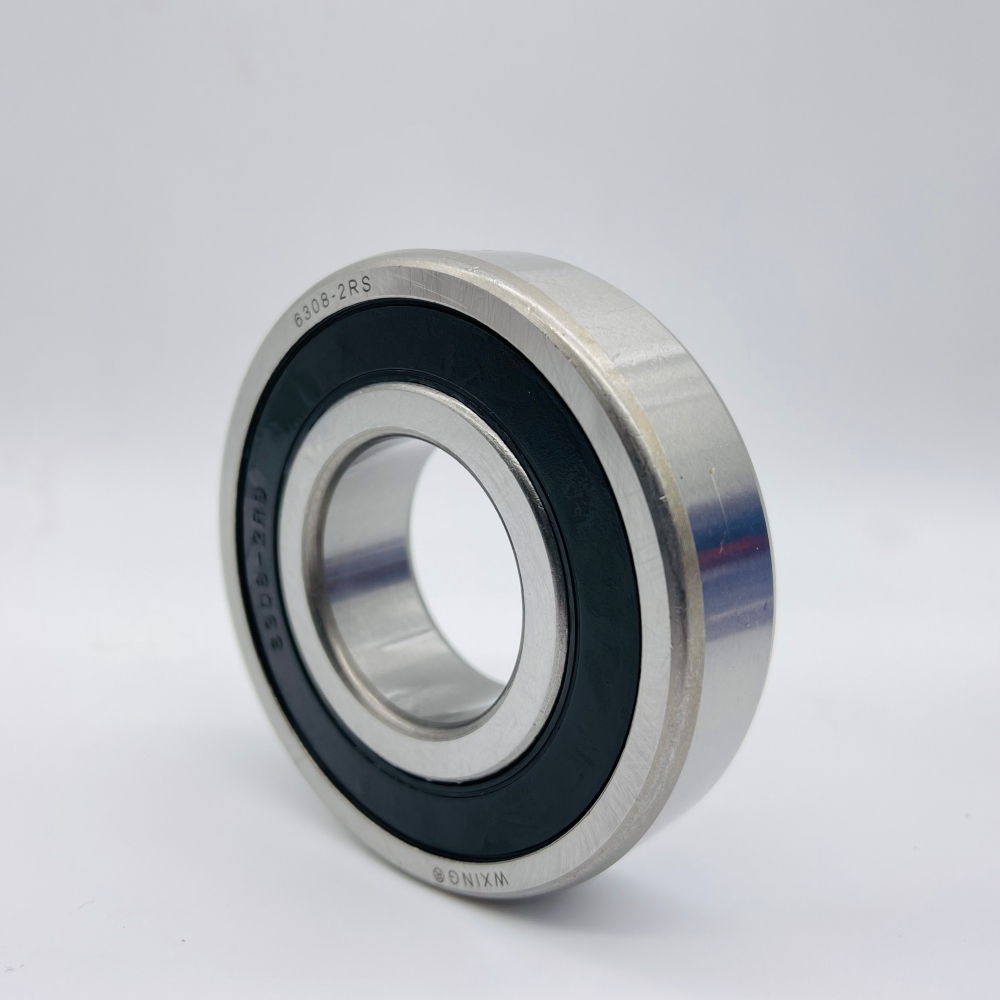

(1) All kinds of cracks, such as raw material cracks, forging cracks, heat treatment cracks and grinding cracks, etc., these cracks will become a source of stress concentration and expand rapidly during the operation of the bearing in the future, causing the bearing to rupture and affecting the bearing life and work. The security impact is huge.

(2) Various mechanical scars, such as abrasions, scratches, crushing, bumps, etc., will cause poor bearing installation, cause unbalanced load and stress concentration, resulting in a decrease in rotation accuracy and service life.

(3) Rust, black skin and pitting, the latter two are defects that are easy to store moisture and dirt, and are most likely to develop into rust. Corrosion is a source of pollution leading to poor installation, early wear and fatigue, and severe corrosion can render bearings useless.

(4) Peeling and folding, the parts of these two defects are not firmly combined with the base metal, and there are often decarburization or carbon-poor phenomena around them to varying degrees, and the material is easy to collapse, dent or wear, which affects the bearing life and accuracy. Very unfavorable.

(5) The riveting or welding quality of the cage, mainly to observe whether the rivet head is misaligned, skewed, loose, lack of meat or "double eyelid", whether the welding position is correct, whether the solder joint is too large or too small, and whether the welding is not strong or welding.

I hope that in this article, from the aspects that need to be paid attention to in the visual inspection, bearing steel has very strict chemical composition requirements, so the chemical properties of bearing steel bearings are very stable, and there will not be much difference in mass production. If you need, you can call us directly.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.