The natural environment of tapered roller bearings

Tapered roller bearings are very common in heavy-duty automotive and industrial applications. Applications can be found in car/truck transmissions and wheel-ends, metal and wind industries, material handling, mining and industrial transmissions.

Typical for these applications are the requirements to accommodate heavy combined radial and axial loads as well as operations with high stiffness. Reliability, durability and the capability to withstand extreme conditions are also important criteria.

Furthermore, and most often, tapered roller bearings operate under contaminated and harsh conditions where the main issue is to ensure uptime.

LOAD RATINGS

Relevance of load ratings

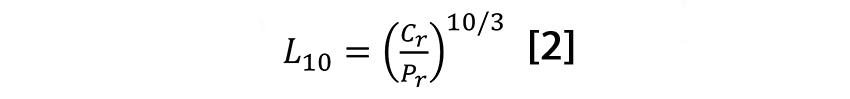

When comparing bearings from different manufacturers, engineers often look at the load ratings as the substantial performance parameter [1]. The dynamic load rating is also key for calculating the bearing basic rating. This can be explained most easily from the life equation.

Calculation to ISO Standard

According to ISO 281, the basic rating life of a radial roller bearing is calculated from:

where

L10 = basic rating life (at 90 % reliability)

Cr = basic dynamic radial load rating

Pr = dynamic equivalent radial load.

According to ISO 281, the basic dynamic radial load rating for radial roller bearings is calculated from:

where

Cr = basic dynamic radial load rating

bm = rating factor of bearing type (value 1,1 for tapered roller bearings)

fc = material/geometry/dimension factor

i = number of rows

Lwe = effective roller length![]() = contact angle

= contact angle

Z = number of rollers per row

Dwe = mean roller diameter.

The relevance of fc as performance factor is very obvious, for example a performance factor of 1.23 results in double L10 basic rating life.

Calculations to US Standards

Sometimes, and especially in the North American market, C90 load ratings can be found. These are based on a rating life of 90×106 revolutions:

where

C90 = basic dynamic load rating based on 90×106 revolutions

M = material factor, defined by bearing manufacturer

H = geometry dependent factor, defined by bearing manufacturer

i = number of rows

leff = effective contact length![]() = contact angle

= contact angle

Z = number of rollers per row

Dwo = mean roller diameter.

Dynamic radial load rating C1 for 1×106 revolutions rating life: